Squeeze energy savings from pneumatic systems

Industrial machines designed to run efficiently and save energy are undoubtedly important considerations in manufacturing today. The reasons not only include rising energy prices and the need to hold down production costs, but also an increasing awareness of the environmental impact on an organization’s sustainability.

These issues should not be the responsibility of only production-floor personnel. Machine and system designers and financial managers have a stake in this as well. Energy can be saved eliminating leaks, system design, and advanced machine diagnostics.

Documented findings

Sachin Kambli, of Festo Corp., Hauppauge, N.Y., cites a study by Germany’s Fraunhofer Institute that examined compressed air systems in the European Union. It concluded that 42% of the total potential savings in optimizing pneumatic systems comes from simply implementing comprehensive leak detection programs. The objective should be to check the pneumatic system completely from the compressor (supply side) to each machine and device (demand side). On the demand side, using a simple ultrasonic leak detector can help manually identify individual leaks on machines — usually for an entire plant.

From there, he says, technicians can categorize leaks by size and importance and record their locations. One of the most common methods is to mark leaks with colored tags containing some basic information:

• location of the leak on the plant floor (included for the audit report).

• approximate leak rate in l/min or scfm.

• classification of leak size and priority for repair.

• repair measures required and list of parts that need to be replaced.

• estimated repair time and, if necessary, additional machine downtime.

• machine accessibility during production.

• remarks concerning general design-improvement opportunities.

This information should be compiled into a report and reviewed by management. Over time, it will highlight problem areas on the production floor. This might include specific types of machines, trouble-prone locations within the plant, or particular designs that could be causing problems. It could also indicate the need to adjust compressor use across production shifts.

Such leak detection programs yield several benefits, Kambli continues. First, leak-detection programs usually need no machine downtime, unless, of course, detection is to be carried out on parts of a machine that are inaccessible when it’s operating.

Second, they are relatively inexpensive. An ultrasonic leak detector is generally priced at $500 to $3000 for a device suitable for most locations and that can detect most leaks. A headset provides noise cancellation, thus permitting use in noisy production environments where leaks may not be audible.

Finally, once leaks are tagged and documented, in-house maintenance personnel can fix them during regularly scheduled machine downtime.

For more information on energy savings through leak detection, system design, and advanced machine diagnostics, visit www.festo.com.

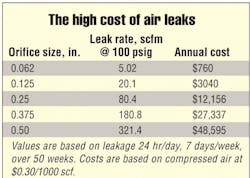

A pair of energy thievesThe most impressive energy savings in pneumatic systems may be realized by eliminating leaks. In hydraulic systems, leaks are quickly repaired due to obvious hazards and the associated cost of hydraulic oil. With pneumatics, leaks are often ignored until they become uncomfortably loud and annoying, or cause such a significant pressure drop that repairs are a must. Many studies indicate air losses from leaks range from 20% to 45%. Left unattended, leaks can grow due to the abrasive effect of airline contamination and particulates attacking the leak orifice. Eliminating wasted air energy and production costs more than justifies the expense of a maintenance patrol that searches out and quickly repairs air leaks. Another, less-obvious source of waste is excessive pressure drop across air filters. In hydraulic systems, excessive pressure drop across a filter can have serious consequences for the entire hydraulic power unit — even resulting in catastrophic failures. Poor maintenance on a pneumatic filter rarely results in sudden system failure. However, excessive pressure drop across the filter is an ongoing, albeit hidden, cost. Using pressure-differential indicators on filters and changing filter elements regularly avoids the escalating cost of pressure drop across the element. Electronic and mechanical indicators are available that provide reminders to service the filters. Pressure switches to monitor pressure drop also help ensure efficient use of compressed air and optimum system performance. |

More on ultrasonic leak detection

Turbulence created by compressed air flowing from a small orifice generates ultrasonic sound, which is directional in transmission. This emitted white noise is created by air moving from a high pressure environment to a lower pressure one. Ambient noise typically found in a manufacturing plant can make it difficult to locate leaks merely by listening for them. However, most plant noise is in the audible range of human hearing, whereas air escaping from a small orifice is ultrasonic.

Exair’s Ultrasonic Leak Detector (ULD) is a hand-held instrument that can locate leaks in compressed air systems. It detects only the ultrasonic sound generated by the turbulent flow of a leak and converts it to an audible frequency that can be heard through the unit’s headphones.

A person using the ULD need only aim it in the direction of pipe, tube, fitting, or port junction. When a leak is present, an audible tone can be heard through headphones and an LED will illuminate. Exair’s ULD can detect leaks as far as 20 ft away, so an initial inspection can quickly be conducted on an entire machine or area.

A ULD can be adjusted to filter out background noise using one of three sensitivity settings. Moreover, a parabolic hood or tubular extension can be attached to the ULD to shield its sensor from background noise. If a suspected leak is in a dangerous or inaccessible area, the extension or hood make it possible to probe these areas from a safe distance to isolate the leak.

One of the most challenging tasks for an Ultrasonic Leak Detector is finding a small leak on the discharge side of a compressor where the fitting connects to the air receiver. This area is normally hot, loud, and dangerous — and using soap bubbles to detect the leak may not work because the water tends to evaporate faster than it can form bubbles. However, the Ultrasonic Leak Detector can find the exact location of the leak. Using the tubular extension may help determine which side of the fitting leaks the most.

For more information on ultrasonic leak detection, visit www.exair.com.