Designing or implementing a vacuum system for material handling applications is an important and often costly expenditure. System designer may receive mixed messages, making the right choice unclear. Engineers should consider the following design parameters: reliability, product safety, efficiency, response time, flexibility, and maintenance issues.

A centralized system consists of one vacuum source, usually mounted remotely, that provides vacuum to multiple use points. This occurs in varying degrees, such as a plantwide supply of vacuum provided by a single central system, individual machines having their own dedicated vacuum pump, or a system where a machine may have pockets or cells of multiple cups operating from a single vacuum pump. Centralized systems are a common design and have some advantages: ease of design and installation, ability to use a vacuum sensor for part presence, no extra hose/line needed for blow-off, and little weight added to an end-of-arm tool setup.

A decentralized system, Figure 1, locates the vacuum pumps closer to the points of use, and can range from a zoned system, where groups of vacuum cups that work together are isolated, to a system where each cup is completely independent of the others. Newer technology and advances in pumps (such as more compact designs) allow for a vacuum generator to be installed at each vacuum cup.

The value of vacuum flow

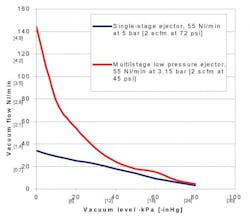

Vacuum flow is important to understand when choosing a vacuum system, yet it is commonly neglected. As seen in Figure 2, a vacuum pump has its highest flow as it operates at or near atmospheric pressure. Vacuum flow then decreases as the vacuum level increases, while the air within the system is evacuated.

When a vacuum cup first makes contact with a part, the flow creates the initial grip that securely grabs the part. Leaks in the system, such as those produced when handling porous parts or materials with a textured surface, rely on flow to maintain vacuum levels. Some designers in the packaging industry recognize the importance of vacuum flow and view it with greater importance than vacuum level. The flow of a system also determines response — and therefore cycle — time.

Although it is easy to understand the downside of restricting vacuum flow, many vacuum systems do restrict flow, particularly in material handling applications. For example, most companies that use centralized systems channel the vacuum flow through tubing and manifolds. These restrictions are probably the greatest factors in reducing system performance and reliability.

Conductor size: a Catch-22

Flow restriction also creates the need to oversize vacuum pumps in order to compensate for line losses. Of course, installing larger pumps increases the system's energy consumption with no additional benefit at the cups. Tubing and manifolds in a centralized system also create additional volume that needs to be evacuated, and then returned to atmospheric pressure during each cycle. Evacuation and release time combined determine the cycle time for a handling application.

Thus, it may seem logical to simply use smaller tubing to decrease system volume and create faster cycle times. However, this only impairs system performance by creating pressure drops and reducing available flow. The resulting flow loss can mean increased response times. Larger size vacuum tubing actually increases system performance by allowing the maximum amount of flow to pass.

With pressure drop through the system caused by restrictions, the vacuum level seen at the pump may not be the same as that seen at the cup, especially with porous objects. It can be misleading to assume that the vacuum level present at the pump is the same as the vacuum level present through the entire system. This causes erratic performance and troubleshooting problems. In fact, vacuum flows and levels at each cup will likely be different if tubing lengths are different, based on their proximity to the pump.

A decentralized approach, with little or no vacuum tubing, minimizes or eliminates the effects of line losses and pressure drops. Higher flows are realized at the cups, and cycle times are decreased due to increased flow and reduced volume. The increased flow adds to the reliability of the system and gives a higher safety margin. Very often, the pumps can be downsized to provide similar performance, and less operating energy will be expended.

Reliability, safety, and maintenance issues

The reliability and safety of a vacuum system is critical — problems may includedropping parts or missing picks. With a centralized design, all of the cups are tied together into one volume, and therefore, when a low flow or low vacuum situation occurs, it affects all cups in the system. For example, if one cup is damaged, or leakage is otherwise present, the resulting vacuum loss will be seen at every cup in the system. Because symptoms occur throughout the entire system, troubleshooting such an event is more difficult and identifying the cause requires time and effort.

Conversely, in a decentralized system, each pump-and-cup combination works independently of — and has no influence on — the others. A leak at one cup can be readily identified and fixed, and will have no bearing on the capacity of the rest of the system. Safe product handling is not as great of an issue with leaks, and downtime due to troubleshooting and maintenance is lower.

Flexibility and energy efficiency

Decentralized systems allow users to control cups and pumps individually to adapt to changing requirements. If they choose not to operate specific cups in an array, users can simply shut down the generator that corresponds to that cup, and expend less operating energy. If the cups link together as in a centralized system, a vacuum valve could be used at each cup, but this does nothing to reduce the pump's energy consumption.

Regardless of the system layout, other application concerns should be evaluated. Consider the operating vacuum levels as they relate to the performance of the system and the amount of energy needed to operate at these levels. It is also useful to consider the size and style of vacuum cups and the effect they will have on the system, as well as the various options available for vacuum generation.

Boyle's Law states that an inverse relationship exists between pressure and volume for a gas at constant temperature, and that pressure multiplied by the volume is constant. Imagine pulling a piston in a cylinder in order to change the internal volume, thereby creating a vacuum in the cylinder, Figure 3. As the internal vacuum level rises toward absolute vacuum, the volume — and the distance that the piston needs to travel — increases toward infinity.

What this means is that to produce a high vacuum level, considerably more energy in the form of piston travel is required than is needed to produce lower levels. The relationship between energy input and vacuum output is not linear but exponential as the vacuum level increases. There is, therefore, more efficient energy transfer when operating at lower vacuum levels. This is similar to the relationship of energy requirements needed to compress air.

In the case of a sealed system, you can theoretically expend up to ten times more energy to receive only minimal gains in holding force at the cup. For an application with porosity or leaks, the effort needed to overcome leakage at deeper vacuums requires significant vacuum flows, and can be prohibitive. Working at lower vacuum levels, where a vacuum pump naturally generates more flow, is a better option. On any system, the response time and release time will be enhanced working at lower vacuum levels, and the life span of the vacuum cups will be increased because of the reduced stresses.

Inevitably, limitations on the design of a vacuum gripper may force the use of smaller vacuum cups and require the use of higher vacuum levels. This is unavoidable in some cases, but if the option to use larger vacuum cup sizes and operate at lower vacuum levels presents itself, this is ideal.

For instance, if we look at a 2-in. diameter flat cup, the rated holding force at 18 in.-Hg is roughly 16.5 lbf. By replacing that with a 3-in. diameter flat cup, the holding force at 18 in.-Hg is now 45 lbf. In this example, by using a vacuum cup with a 1-in. larger diameter, we realize 64% greater holding capacity and have the option of operating the system at a lower vacuum level with no loss of performance at the cup.

The vacuum cup factor

Vacuum cups have a big impact on how a system functions. Because the cups are the portion of the system that contacts the product, it makes sense to evaluate available options and determine the best solution for the application. Although vacuum cups may have historically been viewed as commodity items, they are now considered to be engineered products.

New designs of vacuum cups have been developed with specific applications in mind. For example, in the automotive industry, cups have been developed for durability, coefficient of friction, resistance to machine oils, and mark-free performance. In the packaging industry, cups have been developed for increased grip and sealing capabilities around the lip of the cup. Objects that may not have been considered for vacuum handling in the past — such as high-temperature or unusually shaped items — can now be handled routinely.

New pump technologies

Consider also using some new pump technologies to further improve vacuum system design.

Vacuum generators are being produced today that operate at lower supply pressures without sacrificing performance. Using a low-pressure generator builds safety into the system by effectively eliminating the impact of fluctuating supply pressures, as seen in most manufacturing environments.

Operating at lower pressures also saves energy by reducing the compressed air flow through the nozzles. Using this type of vacuum source in a decentralized system can produce high performance with a minimum of energy. Vacuum generators are also available in a wide range of sizes, with different characteristics to suit applications' vacuum and flow requirements.

Energy-saving devices

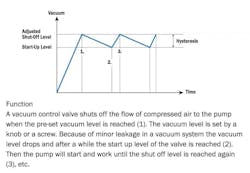

Energy-saving devices, Figure 4, have the ability to shut off the supply of air to the pump while maintaining a preset vacuum level. These simple devices incorporate a valve controlled by a vacuum switch and a check valve in the vacuum line.

The generator will operate until a set vacuum level is reached, then shut off. If the vacuum level drops due to leakage, the pump will turn back on at the startup level of the device. Energy-savings systems should be used with sealed systems and are not recommended for porous applications.

Compressed air vs. mechanical vacuum pumps

Reduction of energy costs is currently the most common form of justification. Generating vacuum using compressed air requires more energy than mechanical vacuum pumps on a straight comparison of equivalent performance — assuming a 100% duty cycle, and comparable pump performance. In reality, however, a compressed air-driven vacuum pump can reduce the energy costs in most applications in several ways:

- Mechanical pumps are generally mounted further away from the application than a comparable air-driven pump. This can be due to space constraints, maintenance issues, or the noise and heat generated by the pump. The need to overcome losses and performance degradation through the required fittings, manifolds, and vacuum lines requires the pump to be sized accordingly. As we have seen, mounting an air-driven pump closer to the vacuum pump, with proper line sizing, can result in downsizing the pump while achieving similar performance.

- Mechanical pumps cannot cycle on and off as frequently as an air-driven pump can. Therefore, mechanical pumps typically run 100% of the time, even though the vacuum requirements at the cups are significantly less.

- An optimally performing vacuum system can increase the productivity of a machine. When decreasing cycle time and increasing the output of a process, production gains can be measured.

- Consider costs associated with maintenance and downtime, which may sometimes only be accounted for after installation.

- While few applications are ever the same in respect to performance requirements and operating parameters, a careful analysis of the vacuum system can help optimize the performance, and benefit the process. Some existing systems that may not have been carefully thought out can see performance increased or costs reduced from an upgrade, while new systems being developed should be optimized for the most efficient performance that will make for a strong handling system.

For more information call (800) 321-7422, email [email protected], or visit www.piab.com.