A look at one of the jeeps that use air springs for realistic, bouncing motions.

Unlike conventional cylinders, air springs have flexible walls that allow the actuator to expand axially like an accordian when air is pumped into it. Because no seals, piston, or rod are needed, contamination poses nowhere near the potential maintenance problems of conventional cylinders.

Improving the ride

A metal cam system mounted under each jeep was used to create vehicle bounce In the Florida attraction. Not only was the metal system rigid and susceptible to the elements, any adjustments in bouncing action required modifying the cam profile.

Convinced that air springs were the answer, Cinnebar developed a prototype vehicle for the Universal Studios Hollywood ride. Golden State Hydraulics provided the vehicles' hydraulic systems, and the project got the go-ahead for production from Universal's Ed Huntington.

Action behind the scenes

The first pursuit jeep (appropriately dubbed a "collision jeep" because one appears imminent) must hurl toward the ride vehicle, decelerate abruptly, bounce and rock in front of the awe-struck public, then quickly return to prepare for the next cycle. The collision jeep assembly is mounted to a sled, which is propelled forward by a single hydraulic cylinder controlled through a proportional valve that maintains acceleration, maximum velocity, deceleration, and return parameters.

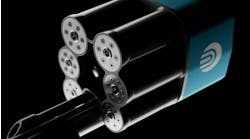

Two four-ply, double-convoluted air springs are mounted to a steel plate which, in turn, is attached to the sled. When pressurized at 65 psi, the air springs lift the vehicle up and help propel it forward. A tank supplied by the building's air system is attached to the jeep and temporarily stores air to provide plenty of capacity on demand. Solenoid valves are switched on and off during the cycle forward, varying the air spring displacement to give the appearance of bouncing over irregular surfaces. "The action appears random and realistic," says Whittier, "but each movement is timed and planned."