Six ADN compact cylinders perform sealing and cutting of the packaging film.

Among the pneumatic motion-control functions, the Rhino 12 uses Festo DNC-80-175 cylinders for die closing, AEVC-25-10 cylinders for film clamping, and ADN-80-30 cylinders for sealing and cutting.

The DNC cylinders in this application have an 80-mm diameter and 175-mm stroke. They are standard, double-acting cylinders made of aluminum alloy with a smooth-anodized finish, and high-alloy steel piston rods. They come with polyurethane or nitrile-rubber seals, although fluoropolymer seals are available. Ambient temperature rating for the standard version is -20° to 80° C, though optional versions handle temperatures from -40 to 120° C.

AEVC cylinders are compact, short-stroke, single-acting units that come in diameters from 4 to 100 mm with strokes from 2.5 to 25 mm. The version used here has a 25-mm diameter and 10-mm stroke. They’re designed to offer rapid response, large clamping force in relation to their size, and require minimal installation space. They have anodized aluminum bodies, alloy steel rods, and polyurethane rod seals.

The ADN products are compact, double-acting cylinders. The Rhino 12 uses versions with 80-mm diameter and 30-mm stroke, but these cylinders are noted for availability in a wide range of variants, configurations, and mounting accessories – thanks to its modular design – letting engineers tailor them to suit specific applications.

They feature anodized aluminum construction, alloy steel rods, and polyurethane or fluoro elastomer seals. Standard, built-in cushioning rings absorb impact energy and thus permit high speeds, fast machine cycles, and long service life.

Controls

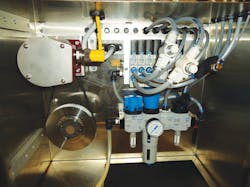

Controlling all the machine’s pneumatic valves is Festo’s VTUB electronically controlled valve manifold. It can hold from 2 to 16 valves on a single manifold, making it suitable for a wide range of pneumatic applications. Valve options include 3/2-way normally open and normally closed; and 4/2-way valves with single or double solenoids. It also handles vacuum applications. Pressure capabilities range from -0.9 to 8 bar and flows to 1000 lpm, and operating voltage ranges from 12 Vdc to 230 Vac. This compact manifold also saves on wiring — the VTUB requires only a single cable with a 26-pin connector to control and activate the manifold’s nested valves.

Festo also offers a valve-terminal configurator to help users more easily select the right version for an application. All terminals are supplied fully assembled and individually tested, reducing installation time for the machine builder.