Troubleshooting Challenge: Drilling Barge with Steering Instability Problem

This file type includes high resolution graphics and schematics when applicable.

An OEM that builds barges was contracted to build a barge with a movable drilling rig mounted on it. The final customer wanted to be able to position the barge, drop the four-corner spuds (outriggers), and drill holes in the port floor as the first stage of deepening the port for the bigger neo-Panamax ships going through the Panama Canal.

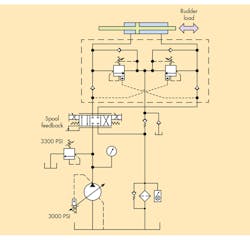

The rudder system used to guide the barge was designed using a hydraulic joystick proportional system. The main feature was the ability to move the joystick to reposition the rudders; releasing the joystick would maintain the new angle position of the rudders. A set of Sun Hydraulics counterbalance valves was used in conjunction with a purging system. A purging system prevents hot contaminated oil from exiting and then re-entering the cylinders without making it back to the tank. The hydraulic power unit would be located about 50 ft from the steering cylinder system with Sun block mounted on the cylinders.

When commissioning the barge, the steering system would not hold its position. It would respond well to a signal to reposition, but when the joystick was released the rudders would move on their own after three to four minutes’ time lag based on the water currents’ direction.

Any idea what the problem is?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing Mindy Timmer. All correct solutions submitted by December 30, 2016, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Paul Lopez, CFPS, from Michaelson Fluid Power, Smithfield, R.I., who correctly answered last month¹s puzzler. A $50 gift card is in the mail to him.

Solution to Last Month’s Challenge: Cylinder Chatter Evades Solution

The use of a counterbalance valve with a proportional directional valve will cause a cylinder to chatter if the counterbalance valve spring chamber drain line is internally drained. As the proportional valve throttles the flow exiting the counterbalance, pressure builds up between the counterbalance and proportional valve due to the restriction. Any pressure that builds up in a spring chamber of any pressure control is additive to the valves spring setting. The proportional was causing the counterbalance setting to vary. Externally draining the counterbalance valve solved the chatter problem.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: