What’s the Difference Between Industrial IoT and Industry 4.0?

Many conversations about manufacturing quickly turn to questions about the future. Will automation and robots take over everything? How are we to sustain growth in our rapidly changing global market? Are we upgrading and investing enough to stay ahead of our competition? Should we be looking at this Industrial IoT thing? What about Industry 4.0? Do we need to pay attention to either if we don’t use that many electrical components? If you are looking to remain a viable business in this next industrial revolution, being aware of and starting to invest in IIoT and Industry 4.0 applications is a requirement, regardless of whether you are a “mechanical-only” company or not.

IIoT is simply about connecting devices on the plant floor, allowing for the development of cyber-physical systems and inter-device communication, which provides new ways to generate and collect interesting data throughout the industrial space. IIoT focuses on selecting devices that can provide visibility down to the lowest points of the production floor, providing visibility into the machine and enabling predictive maintenance and big-data analytics. IIoT is, at its core, about connecting devices. Ultimately, though, by connecting more together, we can improve overall equipment effectiveness and provide new insights into our business.

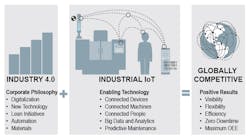

On a grander scale, Industry 4.0 is a blend of digitalization, new technology, and practical decisions focused on dramatically changing how we manufacture products through unprecedented flexibility, efficient production, and visibility at every level of production. Industry 4.0 has impact throughout our processes and across the supply chain. By blending lean initiatives, automation, technology, materials, downtime reduction upgrades, and investments in overall equipment effectiveness, the Industry 4.0 philosophy keeps this generation of manufacturers competitive in a global market.

Although the German government set this tone and direction for Industry 4.0, the entire manufacturing world must now take on this challenge. For example, standard assemblies such as hydraulic power units (HPUs) are receiving a major boost from being IIoT-connected. Traditional on-off flow or pressure switches are being upgraded to smart devices that provide information above and beyond simple switch points. Even traditional analog devices—such as temperature, pressure, flow, and level transducers—can be made IIoT-ready through open standard technologies like IO-Link. These technologies remove the headaches that come from integration of analog technology and add additional value by incorporating easy-to-report parameters, diagnostics, events, and warnings.

A standard HPU can become a smart power unit with minimal modification and provide dramatically better value through predictive maintenance, remote monitoring, and ease of troubleshooting. Imagine not having to climb down into the oil-drenched pit of a stamping press to troubleshoot an issue. With IIoT-ready technologies, we can connect to the devices and know exactly what needs fixing and maybe predict the failure before it occurs. This can dramatically reduce not only machine downtime, but the time spent in hazardous locations as well.

Selecting IIoT-ready technologies is only one step of the program to fully leverage the value of Industry 4.0. We also must analyze processes, determine how flexibility can be implemented into production, and discuss where automation technology makes sense to support lean processes. Manufacturers today can see into every aspect of their production across multiple sites, flexibly manufacture hundreds of variations of product in the same production line, and ensure quality standards with virtually zero machine downtime.

Industry 4.0 is a cultural philosophy about how we can use increased visibility, flexibility, and efficiency across our production to be more competitive. On the other hand, IIoT is an enabling force for Industry 4.0: connecting our devices, our data, our machines, and our people to benefit our company and customers. By embracing both, it is easier to achieve positive results and sustain global competitiveness.

Will Healy III is industry marketing director at Balluff Inc.

About the Author

Will Healy III

Industry Marketing Director

Leaders relevant to this article: