Electric vehicles are quickly becoming essential elements in personal and mass transportation sectors. In mobile machine segments, major suppliers in areas such as construction, warehousing, and off-highway are launching full electric and electric hybrid equipment in response to industry demands to lower carbon footprints and comply with stricter emissions regulations.

These trends are leading to technology innovations in a broad range of construction, agricultural, and other off-highway working vehicles. Original equipment manufacturers (OEMs), drivetrain providers, and other technology suppliers are designing and prototyping ways to use battery-powered electric drives and hybrid electric/diesel drives to move off-highway machines and power their implements.

The push for electrification does not mean the eventual replacement of hydraulics with electric motors will occur; instead, the industry will work toward ways to integrate electrics into off-highway platforms in the most effective ways possible, and to make maximum use of the power density and efficiency provided by hydraulics technology.

Rapidly Evolving Market for Electric-Driven Machines

In the lower-power segment with mobile machines, such as aerial work platforms, forklifts, and commercial lawnmowing systems, battery-electric drives are rapidly replacing combustion engines and even hybrid diesel-electric drivetrains. In most cases, the duty cycle and loads for this equipment allow the battery to be recharged overnight to support a full work shift the next day; this is due in part to improvements in both battery technology and electric motor power and efficiency.

The next round of electrification challenges lies within the larger machines, such as the heavy-duty construction, agricultural, and working machines that typically use diesel engines for their drivetrains and hydraulics to power their implements. This class of equipment is often referred to as the 700-Volt (V) machine class. Industry drivers that are leading to new investments in “electrifying” these kinds of machines include:

Environmental/regulatory concerns. In many major markets, evolving emissions and air quality regulations continue to affect construction OEMs who need to deploy machines that comply with more stringent regulations, yet are still equipped to perform the most demanding tasks. For example, in certain urban environments, noise and emissions regulations have led to OEMs launching all-electric, small skid loaders, wheel loaders, and other equipment capable of working in tight construction conditions.

Total cost of ownership. As electrification expands, the cost of electric drivetrain technology has become more competitive. Combined with the expanding availability of electric charging stations and the cost of fuel, both the long-term value and the potential of electrified mobile machines are becoming more realistic.

Nevertheless, providing the power necessary for construction and off-highway mobile machines to do their jobs every day presents a formidable challenge for electric technology. A fundamental issue is the torque required to do work. Whether that torque is provided by a certain level of voltage and current, the pressure and flow of a hydraulic system or the rotational energy from a diesel motor through a gearbox to a mobile machine’s axles, creating and consistently delivering the power needed to move the machine and/or its load lies at the heart of mobile machine engineering.

How much power is needed—and where do you get it? Fundamentally, demand is driven by the machine’s duty cycle. How far does it travel, how constant or intermittent is that travel demand, and how much power is needed to drive the machine’s implements? If it’s a front-end loader lifting and moving dirt in a construction site, drivetrain power consumption might be less than the load demand on the bucket implements. If it’s battery-powered, a convenient overnight recharge is relatively easy.

Conversely, an agricultural sprayer working in the field is traveling constantly over acres of distance, while the demands on its implements are relatively light. However, if it’s a battery-powered, all-electric vehicle, running out of power in the middle of the field is unacceptable.

To successfully electrify mobile machines, the ultimate question needs clear and reliable answers: How do you replace the power that you have used? With diesel motors running drivetrains and powering implements, the answer has been simple: Fill up the tank. And while battery technology continues to support greater storage, the leap to full electrification for the most demanding mobile machine applications seems difficult to envision.

Innovative approaches are called for in three areas of mobile machines:

- Drivetrain technology: what moves the machine

- Implements: how the mobile machine’s tools are powered

- Intelligence: digital technologies to manage machine functionality and load sharing, sometimes referred to as “electronification”

Modular Approach to Powering Drivetrains

The extent to which different mobile machines can adopt electric drivetrains is led by a matrix of factors, including the size of the machine, its duty cycle, and how much power the drivetrain needs to supply the rest of the machine.

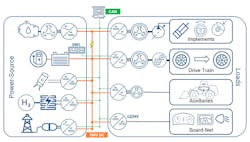

Given these factors, no one drivetrain solution, electric, hybrid diesel-electric, or combustion-only system can supply an effective solution. It makes sense to consider a modular range of solutions. For example, Bosch Rexroth’s approach is based on five mobile machine drivetrain topologies:

Conventional system. Using the standard diesel engine, this approach is still recommended for applications such as heavy-duty trenching equipment, working to dig trenches for pipelines or other long-range projects. The machines are running constantly and operate in remote locations away from electric power infrastructure.

Boost and recuperation. Some machines like excavators may need additional power for certain tasks. While still powered by combustion engines, that engine is also connected to a generator, delivering power directly to implements or the drivetrain, or batteries on the mobile machine. This electric power then “boosts” either the drivetrain or the implements when a task or load requires extra power. This helps save power and reduce emissions by eliminating the need for the combustion engine power plant to increase its output. It can also incorporate technologies like regenerative braking to recover energy after the boost happens.

Hybrid without battery. This application has the diesel engine powering a generator, but the drivetrain is made of electric motors; electric motors are also powering any machine implements. The diesel engine is smaller than if it were carrying the physical load of moving the machine, and there is no extra weight associated with the battery. This design would also typically incorporate technologies like regenerative braking to recover energy during the working day.

Hybrid with battery. This is the standard hybrid configuration used in most passenger vehicles. Power being drawn from a battery charged by a smaller diesel motor helps to reduce emissions. For some construction vehicles, this can be a plug-in hybrid; the battery can be charged from an outlet, so the diesel engine doesn’t have to run to power the drivetrain or implements when the working location is connected to the grid. If the location is more rural and away from the grid, the diesel engine powers the generator that charges the battery.

Full electric. At present, these are plug-in, battery-powered machines with the capacity to support a full day’s workload, operating in settings where noise and emissions restrictions call for all-electric. Machines, such as small skid loaders or telehandlers that have intermittent duty cycles, drive a short distance, pick up a load of drywall, and lift it into a construction site, then sit idle for some time. They provide the best application possibilities for this type of drivetrain with current battery technologies.

As mobile machine builders approach drivetrain electrification, a major concern is balancing the need to deliver enough torque to drive the machine against the need to make the most economical use of electric power. One tool that’s critical to solving this challenge is gearbox technology. Suppliers like Bosch Rexroth have experience building compact, high-performance gearboxes that combine space-saving designs with high-power density and match the gearbox ratio and the hydraulic motor.

Options for Powering Implements

Electrification of mobile machines, unlike passenger cars and other vehicles, requires assessing ways to ensure the machine’s implements have the power they need to do their jobs, day in and day out, without having to interrupt or change construction plans or warehouse operations to recharge the batteries.

Just as with the drivetrain, engineering the drive elements for the maximum load an implement needs to lift or move is one critical calculation. Consider a full-size excavator that must dig and move hundreds of pounds of soil or rocks all day long. Today, that implement is typically hydraulically driven, drawing its pressure and flow from a pump powered by the mobile machine’s diesel engine.

In an all-electric system, it might be possible to power that implement with a heavy-duty electric motor powering a ball screw or other linear component to do the work. However, the size of the actuator to accomplish the task and the drain on the battery could be substantial, even for a hybrid electric platform.

A more effective solution would combine electric power and hydraulic power. It takes a certain amount of power to move a given load—whether it’s voltage and current with an electric motor, or flow and pressure with a hydraulic cylinder, the ultimate result is generating the torque needed to do the work. Rather than power the hydraulics from the diesel motor, the motor runs a generator which, in turn, supplies power to an electric motor driving the open-loop hydraulic pump for the cylinders powering the excavator’s tools. This leverages the proven power density of hydraulics while transitioning how it is powered from the combustion engine platform to electric power.

Electronification can Augment Mobile Hydraulics

In another consideration, the “electronification” and digital transformation shift of mobile hydraulics uses digital machine control technologies to help intelligently manage the torque and power demands within mobile machines, to help keep batteries from being drained before the work shift ends.

For example, electronic load sensing (eLS), an established electro-hydraulic technology that adjusts the hydraulic pump displacement dynamically based on flow and pressure requirements, can be simply adapted and applied to an electrically driven system. A fixed displacement pump could be attached to an electric motor where the pump output is based on the electric motor speed. An electric motor could also be used with a variable displacement pump to increase the overall system efficiency and performance. This is the flexibility electronification provides to a system when taking a holistic and open approach to the torque demand instead of only the power source.

This helps manage the demand on the electric supply and, with a hybrid electric drive or a purely electric drive platform, gives engineers the tools they need to create heavy-duty mobile machines that can do the work without excessively draining the batteries.

Advancing Mobile Machine Electrification

There are technologies in place that can help the mobile machine industry move forward with electrification—including the heavy-duty,700-volt segment serving agriculture, construction, mining and other industries. Companies like Bosch Rexroth have announced plans for 700-volt electric motors and inverters, along with a new generation of gearboxes, hydraulic components, and software that can help mobile machine OEMs expand the use of electric power within their systems.

These technologies can help the heavy mobile machine segment find intelligent ways to fit into a world that is rapidly evolving the electric power infrastructure for transportation, helping reduce emissions and carbon footprints through a range of successful systems that use conventional, hybrid electric, and full electric platforms to provide the next generation of mobile machines.

Terry Hershberger is director of sales product management at Bosch Rexroth Corporation.

About the Author

Terry Hershberger

Director of Sales Product Management, Bosch Rexroth Corporation

Leaders relevant to this article: