Knowing the little details in fluid-power component symbols can make a big difference in an application working or not working, save a lot of time with troubleshooting and make design much more efficient.

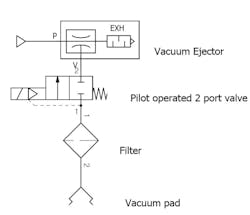

For example, take a look at the schematic below. It shows a basic vacuum pick-and-place circuit. A venturi ejector generates a vacuum and a two-port valve applies or switches off vacuum to the pad. Do you see any issues? Is there a reason the solenoid valve would not operate?

There is a detail in the valve symbol which engineers can easily overlook (and on occasion do), especially if the engineers are unfamiliar with pneumatic symbols. This type has an internal air pilot, and for the valve to open, compressed air pressure is needed at the inlet port (port 1). An internal orifice directs some supply air to an internal piston or another mechanism that moves the valve spool.

Instruction manuals for these types of valves specify a minimum operating pressure for the valve to switch position. This is the pressure which acts on the internal piston/other mechanism, moving the spool to let air flow to the outlet port (open the valve).

If vacuum pressure is acting on port 1, the minimum operating pressure cannot be reached, and the valve remains closed. Not all manufacturers add dashed lines in their symbols to identify internal air supplies to a pilot to make it obvious.

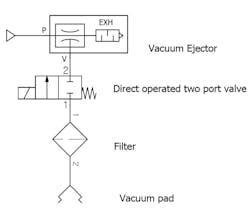

A better choice of valve when using this setup for vacuum applications is a direct-operated type such as the direct-operated solenoid type shown in the example below. These valves do not require a minimum operating supply pressure. The solenoid pulls an internal armature to open the valve or move the spool to allow flow. This type of valve will operate under vacuum pressure.

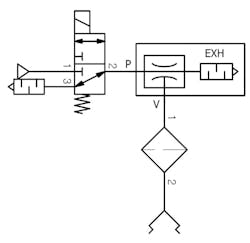

Astute readers will have noticed that the above setups are not the most efficient way of supplying vacuum for pick-and-place applications. In this case, the ejector still consumes air to create vacuum even when vacuum pressure is not required, such as when a workpiece has been placed and the robot head is travelling to collect the next piece. When vacuum is not required, shutting supply air to the ejector saves a lot of energy. The schematic below shows how using a 3-port valve before the ejector can do this.

When the solenoid is energized the valve opens, letting pressure act on the supply port of the ejector (as this is positive air pressure, an internal pilot valve would be suitable as well). The solenoid can be de-energized when the object being picked is to be placed down. Port 3 on the valve exhaust airs from the ejector, which turns off vacuum pressure, releasing the workpiece.

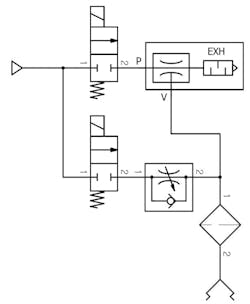

It can still be more efficient. If fast cycle times are required, consider using positive air to release the workpiece from the pad quicker and more cleanly (on occasion, workpieces stick to a vacuum pad). By using two 2 port valves, one can supply the ejector, and when it is time to release, cut supply to the ejector and use the other to supply pressure to the pad, releasing the workpiece cleanly. When doing it this way, it is a good idea to use a speed controller in the release air line, as too much flow could blow a light workpiece away from where it is supposed to land.

Could it be even more efficient? If the budget can handle it, a PLC would allow pressure switch to be added. This lets the vacuum pressure switch tell us when the vacuum pressure needed to lift our object has been reached and we know the pad has gripped the object. If we cannot add the PLC and switch, mis-picks can go unnoticed, which may cause snags down the line when customers orders arrive short, or a packing sequence gets disturbed.

Another advantage of a pressure switch is that it can highlight when maintenance is needed. When pads become worn or damaged, the application will experience leaks. If the pressure switch takes longer to detect the required vacuum pressure, or doesn’t detect it at all, it will alert a technician to examine the pad, tubing, fittings and other components for leaks. Regular maintenance and correctly operating machinery bring down running costs of an application (leaks cause machinery to consume much more air and, in turn, energy than they should).

If a company is going to buy all these components separately, it might be worth considering buying an all-in-one ejector, which includes supply and release valves, filters, a speed controller for release air and a vacuum pressure switch. There are several of these on the market. Some include an energy-saving option, which cuts compressed air supply to the ejector once an object has been picked by the vacuum pad.

Once the object is picked, the pressure switch detects that the required vacuum pressure has been achieved, and the supply valve cuts compressed air to the ejector. An internal check valve holds vacuum pressure, which holds the picked object without the ejector producing more vacuum. The switch detects if there are any leaks and only lets compressed air supply the ejector if more vacuum is needed.

When it is time to release the object, the supply valves direct compressed air to release the object (only for a very short burst to release). The initial cost of an all-in-one ejector seems high, but if used intelligently, the savings it returns in the long run definitely make it worth the initial investment.

Wayne Wilding is with technical sales support at SMC Corp.

About the Author

Wayne Wilding

Technical Sales Support, SMC Corporation

Leaders relevant to this article: