How Trends in Fluid Power Affect Sealing Technology

With growing opportunities to grab major construction projects around the world, fluid-power customers are relying on equipment manufacturers to build machines that perform reliably in any environment without needing for frequent maintenance. Meeting these expectations can be challenging and requires components that can handle extreme temperatures, wet and dry conditions, and constant heavy-duty operations, and that includes seals and gaskets.

To design and manufacture the durable and gaskets that keep hydraulic cylinders, pumps, motors and valves operating smoothly, suppliers must stay ahead of their customers’ requirements. One method of doing this involves analyzing industry trends and their role in developing new fluid-power materials, designs and products. Here are six industry trends that will influence the research and development activities pursued by fluid-power suppliers.

Customization Within Standardization

Standardization is a universal industrial trend that has driven realignment in many industries. The automotive industry, for example, successfully established a standard platform vehicle strategy several decades ago. Mirroring a similar mindset, many of today’s fluid-power cylinder manufacturers no longer offer different cylinders for different applications. Instead, they provide standard cylinders with broader performance capabilities. The benefits of this approach include lower development and SCM costs and faster responses to the market.

But there are challenges to this approach. Standard cylinders with standard seals are not designed to address all application conditions (including different pressures, temperatures, fluid mediums and friction) and environmental challenges such as humidity. All these conditions affect the cylinder’s ability to operate flawlessly for long, maintenance-free hours. That still takes customization.

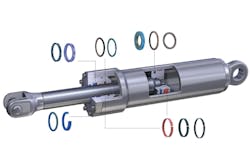

One approach cylinder manufacturers can take is to use sets of seals that have been developed for different applications. These sealing platforms fit standard cylinder gland dimensions but are packaged with specific bundles of wipers, primary seals, secondary seals, and rod bearing and piston bearing elements. Seals are not the only cause of cylinder leaks. It takes matched platforms of sealing components working together to reduce friction, eliminate leaks and increase the cylinder’s reliability for specific tasks.

With radial shaft seals, there is even more at stake. These seals are used in construction and agricultural equipment and interact directly with the shaft and the bearing. The collateral cost of a poor-quality seal can be extreme. Using standard radial shaft seals doesn’t just cause premature equipment failure and leakage; it may destroy the shaft bearings, the shaft itself and even the housing if the heat gets too high. Radial shaft seals must be customized by size and material to address different applications. Customers are beginning to realize that installing correctly dimensioned, premium radial shaft seals ultimately saves money.

Global Machines

In the past, different regions of the world have relied on fluid-power machinery manufactured to handle regional performance challenges such as extreme temperatures, dry or wet conditions, and terrain from mud to ice. Thanks to improvements in machine engineering, it is now possible to manufacturer equipment that withstands a broad range of the extremes the world has to offer. But what about seals inside these machines? They must also meet a myriad of performance challenges to keep equipment running.

Ideally, suppliers should offer customers a universal seal that reduces part complexity and engineering costs and streamlines order processing and SKU counts. These seals must handle all the challenges fluid-power machinery encounters, including extreme environments, high and low temperatures, widely fluctuating pressures and different sustainability requirements. One way to achieve this is by using advanced materials.

Experts estimate that materials account for 80% of a seal’s performance; the other 20% is attributed to design. Polyurethanes have been a standard choice for the dynamic seals required in fluid-power applications for decades. Recent advancements, however, have produced new polyurethanes that handle a broad temperature range, different environments and long operating hours machinery throughout the world requires.

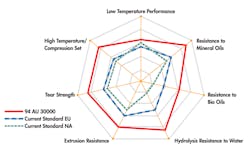

For example, Freudenberg’s 94 AU 30000 polyurethane is specifically developed to address these challenges. Seals made from 94 AU 30000 better resist water and synthetic hydraulic fluids, withstand aggressive temperature fluctuations, and are more resilient to wear. They also are less prone to damages caused by fluctuating pressure peaks which might occur when a backhoe repeatedly pounds on a boulder to remove it.

Bigger Machines, Bigger Cylinders

Another fluid-power trend is the use of bigger, more powerful machines in regions where infrastructure demands are still growing. Larger machines require larger cylinders and seals and generate higher energy densities that put new demands on the seals. Replacing these seals can be a difficult and costly task. Many of these massive machines operate in remote areas on challenging terrain, so when one goes down, repairs can take days while replacement parts are shipped. To address these risks, operators are looking for seals that maintain the performance capabilities while extending trouble-free operation.

The design of piston-ring seals for such a large piece of equipment can be tricky. By testing the performance boundaries of selected seals, Freudenberg developed the HDP330 high-pressure piston seal that can handle the increasing pressure demands while maintaining trouble-free operations. This two-part seal consists of a PA slide ring with a stepped cut and an elastomer contact-pressure element. It offers extreme strength against gap extrusion due to the sliding component, plus high abrasion resistance and pre-loading force.

As the performance requirements of fluid-power seals continue to push the limits of existing technology and materials, more fluid-power customers are seeking technical solutions like the HDP330. For its part, this piston seal can be affordably modified and quickly installed in a variety of fluid-power applications.

Environmentally Friendly Fluids

Requirements for environmentally responsible industrial operations are growing around the world. Customers are requesting fluid-power machinery that is cleaner, quieter and less likely to expose fields and construction sites to industrial contamination. One way fluid-power manufacturers are answering this call is by using more environmentally friendly lubricants and hydraulic fluids. Using biodegradable oils, for example, is the growing response to potential leaks in farm equipment.

Although these new lubricants and fluids are better for the environment, they can also wreak havoc on traditional seals. These liquids frequently contain aggressive compounds that weaken and break down elastomer bonds in standard sealing materials. It takes material expertise to properly analyze the of sealing materials and fluids. A dual approach could be the best solution. It couples the development of internationally compliant materials with fluid-producing manufacturers testing for compatibility.

Freudenberg, for example, has established engineering centers in Europe and North America that offer fluid-power customers advanced testing protocols and validation measures that save time and money. These centers are equipped with state-of-the-art equipment that track pressure, temperature, frictional torque, changes in mechanical properties and leaks while characterizing interactions between tribological systems and diagnostics in seals and sealing components. They also incorporate future-oriented technology to address environmental requirements in fluid-power applications.

Less Work and Time Invested in a Cylinder

Build and design standards for hydraulic cylinders are well established. Materials, surface finishes and best design practices are well understood and have been universally applied throughout the industry for decades. So, everyone is aware that a seal’s price is a small part of a hydraulic cylinder’s overall costs. This means that reducing seal prices has a minimal impact on cylinder cost. Today’s customers look for ways to address the primary expenses involved in cylinder manufacturing, including the materials, machining and labor. They are asking how innovative approaches to cylinder designs and materials can significantly lower the overall cost of hydraulic cylinders.

Recently, one such approach has emerged. By designing the cylinder around a seal package and investing in high-quality seals, companies can significantly reduce the time and work needed to manufacture that cylinder. Cost reduction factors such as rougher surface finishes on tubes, wider tolerances and extrusion gaps, shorter glands, and even eliminating components such as back up rings and buffers, become possible when a seal package is specifically designed for an application. The payback on such seal packages many times greater than the initial investment.

This is the underlying approach our company’s Perfect Cylinder Program offers customers. By working with cylinder engineers to design cylinders around sets of high-performance seals, other areas of cylinder production that account for a significant portion of the cost can be reduced. With this approach, company experts work with customers to reengineer hydraulic cylinders and pair them with the high-performance seals that increase efficiency while lowering the cost of machining and labor, among other factors.

This approach also addresses the need to offer advanced materials in the fluid-power industry. For example, one seal package combines components made of 94 AU30000 polyurethane, the HDP330 high-pressure piston seal and the company’s Guivex guide bands that can handle 40% higher side loads. These reduce cylinder length and material needed while improving cylinder efficiency and saving customers as much as 40% on material and production expenses.

Smart Seals Reduce Maintenance

All manufacturers are interested in eliminating the time and cost of unnecessary maintenance on equipment. However, the push to do so is even higher in some fluid-power applications, such as offshore windmills where the components’ size and location being maintained are extremely remote and challenging. In such cases, maintenance personnel often walk a balance between frequent component inspections that don’t require service, wasting significant time and money, and too few inspections, which may save money and time, but increase the risk that problems may not be caught in time to prevent serious damage or downtime. With these kinds of fluid-power-applications, customers want new ways to control time and costs.

Smart seals are one option. They are already being developed and promise to significantly reduce maintenance costs by monitoring the lubrication subsystem and sending alerts when specific parameters are reached. Looking ahead, smart seals will become important for many fluid-power applications and manufacturers need to invest in technologies that support their development.

There is already an oil seal at our company that includes a detector. It has a small sensor that send out a signal if it gets wet, alerting operators to a leak and the need for maintenance. In addition, the company is working on a shaft seal that measures its own wear by sensing when the wall of the seal gets thinner, signaling a need for service.

The capabilities of smart seals are still emerging, but they fit well in an industrial environment where machines learn and are connected to one another, and where seal condition can be critical for a machine’s performance and profitability.

Christian Dickopf is vice president of general industry and regional manager of NAFTA for Freudenberg Sealing Technologies.