“Lightweighting” is a term used to describe a method of combining advanced technologies to manufacture similar, much lighter components. This concept is familiar to the auto industry, which has been manufacturing automobiles of all sizes that weigh a fraction of their predecessors. With Federal Corporate Average Fuel Economy (CAFE) standards requiring an increase in fuel economy and lower CO2 and NOx emissions for consumer vehicles and light trucks by the year 2025, regulations are driving the auto industry to innovate and find lighter solutions. Larger on-road vehicles and mobile equipment are also being required to comply with government regulations for lowering fuel consumption, reducing emissions, and meeting company expectations of decreasing operating expenses at the same time.

Even though these composite accumulators look much like their steel counterparts, the composite construction reduces weight to a fraction of that of steel. The result is high power density and the potential for much lower installation costs.

Fuel-efficient engines and lightening the vehicle structure are primary tactics implemented in improving mileage and reducing emissions. The top three materials the auto industry has focused on to accomplish these goals is high-strength steel, aluminum, and carbon fiber. Each high-strength, lightweight material will decrease the weight of a vehicle and, when used in conjunction, may result in significant weight savings over a heavier steel vehicle with equal strength and safety.

Lightweighting also translates into applications such as on-road and off-road mobile equipment as well as general industrial applications. Every pound counts in some way. Driving heavy equipment to a site, harvesting equipment on a farm, or operating an excavator in a construction site increases operating expenses if this equipment is heavy. Heavy vehicles or transport vehicles operating on-road are subject to additional taxation, environmental regulations, and permitting fees. That, added with fuel charges, can sends costs soaring. The operational cost of weight is expensive.

Fluid Power as a Plus

Large OEMs face client demands and government regulations for product fuel consumption and emission restrictions encouraging them to design lighter, more efficient but equally durable vehicles. One solution is hydraulic hybrids, which use fluid power to store and reuse braking energy in hydraulic accumulators. Parker-Hannifin, Lightning Hybrids, and others are on the cutting edge of developing and commercializing hydraulic-hybrid vehicles that not only conserve fuel, but also extend the life of vehicle braking systems.

Some of these hybrid vehicles boast a 40% to 50% decrease in fuel consumption and emissions due to these technological advances. This energy recapture and release coupled with lightweighting vehicles results in an outstanding cost savings over the long-term capital investment. Lightweighting is critical in maximizing benefits on a hydraulic hybrid vehicle platform, but can also provide substantial gains in many other hydraulic applications.

Most Bang for the Buck

Pick your heaviest essential components and make them weigh less. Sounds simple, but his is a significant design challenge for hydraulic hybrid companies. In order to achieve the maximum fuel efficiency, engineers must look for ways to lightweight the accumulators on the system while staying within budget.

Reconsidering material selection is a clear first step in reducing the weight of the accumulators, which leads quickly to candidates such as lighter carbon-fiber composites and aluminum. But carbon fiber and aluminum both come with a hefty price tag—right? Not always. Many engineers and end users are finding the price of composite accumulators is only slightly higher than traditional steel, and the long-term operational costs usually offset the initial investment.

Accumulator Shell Types

Hydraulic accumulators—specifically, bladder accumulators discussed here—have been used in industry for years (see "The Many Roles of Accumulators"). The most common type of accumulators used today feature a steel shell to withstand the high pressures and high number of cycles required of an accumulator. This type of accumulator is classified as a Type 1, which means the shell is all metal (carbon steel, stainless steel, Inconel, etc.).

There are essentially four types of high-pressure accumulator shells: Type 1-all metallic; Type 2–metallic with hoop overwrapped composite shell on the cylindrical section; Type 3–metallic liner with complete composite overwrap;, and Type 4–plastic liner with complete composite overwrap. Types 2, 3, and 4 are all examples of lightweighting the accumulator shell, with Types 3 and 4 producing the most significant impact in weight reduction. Companies like Hydac, Parker Hannifin, and Steelhead Composites all offer off-the-shelf lightweight accumulator solutions.

Strength, Weight, and Safety

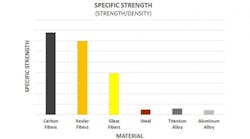

It may seem hard to believe that something made of carbon fiber and aluminum would possibly stand up to something as strong as steel. However, studies and testing show that engineered composite structures can far exceed the strength of steel. Due to the low density, high strength, and excellent fatigue characteristics of carbon fiber, composite accumulators can provide pressure rating equal to steel accumulators while weighing only one-third to one-quarter the weight of their traditional steel counterpart.

In today’s hazardous world, human health and safety is at the forefront of our minds. Some of us have witnessed the results of catastrophic damage a pressure vessel can cause when something goes wrong. Composite accumulators offer additional built-in safety: a leak-before-burst feature. When the composite accumulator has reached its fatigue life, the vessel liner will simply leak, and pressure will slowly escape through the carbon fiber composite shell. This safety feature has been found to meet the rigid standards of the U.S. Department of Transportation.

An optional safety feature is a heat-activated pressure-relief device for the quick release of the nitrogen charge stored in the bladder in case of fire. Furthermore, composite accumulators offer a huge advantage in applications where rusting and corrosion is an issue. Personnel or passengers can get peace of mind that the composite accumulator is not rusting when exposed to otherwise corrosive environments, which would not be the case with unprotected steel accumulators.

Testing

New technologies are always closely scrutinized, and composite accumulators are no different. However, no set standards exist for accumulators on mobile vehicles. Manufacturers of Types 2, 3, and 4 composite accumulators follow the testing guidelines set forth by the Compressed Gas Association, Natural Gas Vehicle Institute, International Standards Organization, and American Society of Mechanical Engineers. Manufacturers such as Steelhead Composites perform rigorous testing on the accumulators to further develop and improve the design and cycle life of the vessels.

Although steel accumulators have been proven in the field to last for millions of cycles, composite accumulators are being evaluated and optimized for cycle-life performance in relation to their end application. Currently, we have tested more than 250,000 cycles under rigor and stress that far exceed the drive-cycle characteristics of the hydraulic hybrid vehicles for which these accumulators are being used. Cycles of a million plus are on track to be achieved with the help of advanced engineering, material treatment, and extensive testing.

Operation and Maintenance

Composite accumulators made by Steelhead are light yet tough, repairable, and easy to install. The structural shell of carbon fiber and epoxy composite overwrapped over aluminum liner provide for a strong and tough structure. A sacrificial layer of glass fiber and epoxy composite creates a strong barrier against impact damage and road debris. Optional shell coatings can provide an additional layer of protection from the surrounding elements in corrosive environments.

OEM replacement parts and instructions are available for trained personnel to perform standard bladder repair and maintenance resulting in a longer service life. Top-repairable models are also available that make bladder replacement simple by allowing removal of the bladder through the accumulator’s gas-port end, thus eliminating the need to remove the accumulator from the hydraulic system.

Additional savings can be captured in the ease of installation with less labor and possibly eliminating expensive lifting equipment normally required with heavy steel accumulators. In addition, due to their size and light weight, these composite accumulators can be installed overhead, saving valuable floor space; skid-mounted for mobility; or installed in vehicles as in the case of hydraulic hybrid retrofit systems. Ultimately, lighter weight means composite accumulators can be installed where needed or where it is most convenient, instead of forced into locations due to weight restrictions.

Industry Compatibility

Traditional steel accumulators have large openings so that bladders can be maintained easily. Steelhead’s composite accumulator ports are no different in that they are designed with a threaded (or flanged) steel port interface with an industry-standard 3.5-in. (89-mm) diameter port opening on the hydraulic end. The large port opening not only allows easy removal and installation of the bladder, but also accommodates a bladder with a wall thickness that ensures low permeability and longer life span for the bladders. An industry standard port opening also means allowance for maximum fluid flow rates common to the industry.

In addition to industry-standard features, composite accumulators can be engineered to specifications and prototyped in-house allowing for greater design flexibility. Some suppliers offer short lead times along with specific volume and pressure customizations.

Hydraulic accumulator technology has not changed much over the last 50 years. However, the many advantages composite accumulators in both existing and new mobile and industrial applications should herald an increase in their use. This is especially true in factory settings, where the lighter weight of composite accumulators reduces installation cost.

Kaushik Mallick is director of engineering at Steelhead Composites LLC, Golden, Colo. For more information, call (720) 524-3360 or visit steelheadcomposites.com.