HydraForce Partners with Tan Delta and Elevāt to Optimize Hydraulic System Maintenance

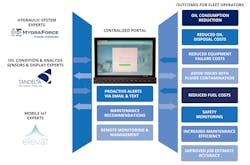

HydraForce is collaborating with Tan Delta and Elevāt, a provider of IoT connected machine applications, to improve maintenance of hydraulic systems in mobile equipment. Elevāt's telematics solution will be integrated into hydraulic systems utilizing HydraForce technology, allowing the monitoring of system performance.

In October, the company announced a partnership with Tan Delta Systems — a manufacturer of real-time oil quality monitoring sensors. Through this partnership, Tan Delta's oil conditioning sensor can be integrated into manifold assemblies equipped with HydraForce's cartridge valves. This enables continuous monitoring of hydraulic oil conditions.

Adding Elevāt's technology to the mix will help machine users be more proactive with their maintenance practices. Its telematics solution provides a centralized portal through which hydraulic system information can be collected, analyzed and sent to machine owners and maintenance personnel as necessary. Email and text alerts can be sent, helping to ensure timely action for any hydraulic system maintenance needs.

“Elevāt’s Machine Connect application is paired with the Tan Delta oil conditioning sensors to provide operators with machine operational data and deliver customized alerts to inform the operator or owner when hydraulic fluids require maintenance. The combination of an electronic controller architecture with telematics provides multiple benefits to users, including real-time data and ongoing alerts of oil conditions. The reported information will prevent excessive wear of hydraulic components and catastrophic failures that can occur when machines are in operation, thus, leading to increased productivity, and reductions in machine downtimes and maintenance costs,” said Russ Schneidewind, Director of Business Development, HydraForce, in the press release announcing the new partnership.

READ MORE: IoT Enables Better Problem Solving in Fluid Power

“Through accurate monitoring of oil health, maintenance scheduling can also be optimized as equipment is serviced only when required, and operators can rest assured that any unexpected changes in the oil condition will be immediately detected and reported. This can also extend the operational life of equipment and overall machine health, as optimal oil conditions prevent unnecessary wear and tear,” explained Chris Greenwood, Managing Director, Tan Delta Systems.

Power & Motion spoke with Adam Livesay, Co-Founder, Elevāt, about the partnership and how the technologies can work together to improve maintenance and monitoring of hydraulic systems.

*Editor’s note: Questions and responses have been edited for clarity.

Power & Motion (P&M): How does the Elevāt telematics solution integrate with the HydraForce and Tan Delta technologies?

Adam Livesay (AL): We share a lot of the same OEM and channel partners as HydraForce, so we have been working together inside partners and OEMs for a number of years now. We started working with HydraForce on their telematics strategy early this year, late last year. They take a unique approach in which they provide more of their subject matter expertise to their components and the applications their components power. They have a lot of history, data and information to give customers.

The Internet of Things (IoT) accelerates that because now they can share what they as a supplier know about the way their components are operating with the OEM or channel partner and ultimately the end user. Five years ago, that was not really the case with fluid power suppliers. That was kept internal. We’ve seen this change with our [various] partnerships.

I think we both have the same vision that companies are going to partner together to provide value and information to the OEM, and ultimately the end user, to drive better machines, maintenance outcomes, you name it.

HydraForce has a unique partnership with Tan Delta [to use its] oil condition monitoring sensor. In fluid power, oil condition monitoring is always one of the pinnacles for preventative and predictive maintenance. One of the major barriers to entry is the cost. [Previously HydraForce] was not able to get accurate and repeatable information packaged in a sensor solution like Tan Delta offers. Tan Delta’s sensor is the first I’ve seen that meets a commercial price point as well as [level of] accuracy [beneficial to the market].

We are really excited about this because we’ve been asked as an IoT company how we can get information about the oil in the hydraulic system, information about the health of the oil in gearboxes, all these different things on a machine but in a cost-effective way. And Tan Delta seems to be the answer.

By bringing these three partnerships together, where HydraForce works really closely with Tan Delta, they work closely with us, we work closely with the OEMs and HydraForce, we [can say] here's another piece of the puzzle, another piece of this ecosystem has been created of companies that are providing the next generation IoT solutions to their customer.

P&M: Can you talk about how bringing all of these technologies together will help with remote diagnostics and predictive maintenance?

AL: There are [several] sensors on a piece of machinery…[those for the] hydraulics are all connected through a HydraForce gateway. The gateway connects to Elevāte.

One of those sensors is this Tan Delta oil quality sensor. It can give a read on current hydraulic oil condition and temperature. It will [provide this information] and the rate that those things are changing over time. This gives the fleet owner or machine operator immediate visibility into the current state of the oil within the hydraulic system. They can take immediate action if the oil condition starts to deteriorate because that is a major leading indicator of wear and component failure.

Two of the major use cases here are going to be reducing unplanned downtime and managing part and repair schedules for machines which is a big deal right now because of allocation of parts and service costs going up.

Oil quality is probably the most important thing to determine the health of a hydraulic system. Right now if a machine goes down, a service company goes to [inspect it] and brings big, bulky oil monitoring and filtration systems to determine the health of the oil and diagnose the problem. Now that can be done remotely [with the HydraForce, Tan Delta and Elevat technology].

READ MORE: IIoT-Enabled Pneumatics Improves Packaging Operation

P&M: And the telematics system is analyzing the information?

AL: Yes. The first step in the process is data collection. We have implemented best-in-class sensors from Tan Delta and software, which is the Elevāt portion, along with the HydraForce gateways. We are capturing machine data across all assets.

Next, we would provide data visualization. Customers will see their equipment health and the performance impact across all of their equipment that has these sensors on it. Step three is automating alerts. Based on the data coming off that sensor, we can implement known thresholds or performance and send that information to the right people in a fleet’s organization.

The final step, the cool part with Tan Delta, is we have the predictive intelligence. When we see rates of change in that hydraulic oil condition and temperature, we can start making predictions on the degradation of that component or machine.

P&M: Was there anything special done on the design side of things to make sure the technologies from HydraForce, Tan Delta and Elevat work together?

AL: The three companies have all been working closely together for this past year. What we have been doing is deploying the Elevāt software on HydraForce gateways and hardware. Tan Delta has their own internal software and data sets we have integrated into. Therefore, we can get the sensor flowing seamlessly – from the machine to the sensor to the gateway to the Elevāt cloud.

Once that data is there [in the cloud], we can read that information and use the proprietary Tan Delta database, datasets and algorithms to perform predictive maintenance and automate alerts to customers.

There is collaboration from all three of us to get tight integration into an ecosystem which provides results to the end customer.

P&M: Do you see partnerships like this, and the integration of telematics and IoT into fluid power systems, becoming more prevalent for mobile equipment?

AL: I see it [has] accelerated for sure. We have a number of other partnerships we are working through right now around component manufacturers, sensor companies, and traditional fluid power component manufacturers.

A couple of years ago, one company would try to provide the entire solution. That has shifted. Now the power is in the OEM’s hands and suppliers are figuring out how to build ecosystem partnerships so the OEM ultimately has the highest value of [technologies] coming together. And they are not forced into one type of product.

This is a [situation where] the sum of the parts are greater than the one company. We are excited about it because we always believed this was going to be the case; sometimes you are going to be the solution, other times a puzzle piece of the solution. And it seems the market has really shifted that way.