New Hydraulic and Electric Motion Control Solutions for Construction Equipment

The 2023 International Fluid Power Exposition (IFPE) and co-located CONEXPO-CON/AGG was filled with new product launches from manufacturers in the fluid power and electric motion control industries. These products included so-called traditional hydraulic and pneumatic components as well as advancements in electric actuators, electrification solutions and more.

Visit our IFPE channel for more news, video interviews and more from the year's largest event dedicated to the fluid power, motion control and power transmission industries.

With the range of products launched at IFPE & CONEXPO, it is evident that the fluid power and electric motion control industries continue to innovate in order to meet the needs of OEM customers in the construction equipment and other heavy machinery industries. The array of new technologies introduced also shows just how much the mobile equipment industry is changing, with trends such as electrification and automation bringing about the need for new components and system architectures.

Also driving technology designs is the increased desire from OEMs and their customers to improve the efficiency of their machines as well as increasing connectivity and data collection.

Lee Co. Introduces DL Series Plug

The Lee Company has introduced the DL Series Plug to its product offering. Featuring a patent pending design, the plug permanently seals passages using the company's new Drive Locking technology which retains plug and seal passageways for the life of the application without the need to use pins, sealants or other sealing devices. According to the company, this helps to simplify installation and reduce costs.

Installation is further simplified through the inclusion of an Installation Indicator feature which provides users with a visual indication of any gaps which means the plug has not been installed correctly. If installed correctly, the Installation Indicator will come in contact with the housing wall and no gaps will be visible.

The DL Series Plug features a single-piece, stainless steel design which is rated for pressures up to 69 bar. Five standard body diameters are available from 4-8 mm. The plug suits use in cross-drilled holes in aluminum manifolds used in transmissions, electric drive units, industrial hydraulic systems and more.

Bosch Rexroth Expands Hägglunds Motor Line

At IFPE, Bosch Rexroth introduced its Hägglunds Quantum range of hydraulic motors. The motors are designed to improve torque and speed capabilities while maintaining efficiency for direct drive applications in heavy-duty equipment.

The Quantum motors provide a top speed of over 150 rpm and maximum torque of more than 350 kNm. Changes to the design and materials used enabled the increases in speed and torque, as well as a longer lifespan while ensuring efficient operation.

READ MORE about the Hägglunds line and its Atom motor, a winner in the Motors and Drives category of the 2022 IDEA! awards.

Two motors are included in the Quantum range, which replaces the previous Hägglunds CB, the Hägglunds Quantum and Hägglunds Quantum Power. The motors have a similar design although the latter is able to achieve particularly high speeds at full torque capacity and high levels of efficiency. It is able to do so due to the use of a new slim connection block which works together with the motor's additional ports and optimized channel geometry to improve upon the performance of previous versions. All of this is possible without adding size or weight.

Environmentally friendly fluids can be used with the new Hägglunds motors which was a key design criterion for the company said Wolfram Ulrich, Vice President Sales, Hägglunds, during Bosch Rexroth's press conference at IFPE where it introduced the hydraulic motors.

Ewellix Launches New Electric Actuators, Assembly Kit

Linear motion technology provider Ewellix launched a new generation of electric actuators as well as a kit to aid the assembly and specification of electric linear actuation systems at CONEXPO. The company's new electric actuators are designed specifically for use in mobile equipment applications, providing the power density and motion control needed in construction, agricultural and other heavy machinery.

Ewellix plans to initially release actuators with 3- and 15-ton lift capacities. Future models will provide additional capacities and a steer-by-wire option. The actuators will provide OEMs with an alternative to hydraulics which the company says is clean, easy to install and offers a lower total cost of ownership. These new actuators are based on Ewellix's CASM series and can be equipped with safety features such as a descent speed limiter, back-up nut and electromechanical motor braking which help to provide similar functionality as a hydraulic cylinder.

While the new electric actuators will feature the same robust and modular construction as the CASM series, they will also offer a more compact design and wider range of end attachments. A higher efficiency motor package with IP ratings suitable for off-highway equipment applications will also be available. Maximum linear speeds (unloaded) up to 300 mm/sec, at accelerations of up to 6 m/sec, and stroke lengths of up to 2 m will be possible, depending on the application and configuration.

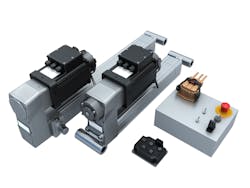

Ewellix also introduced its eMOVEKIT as a means of reducing design and validation time for OEM customers. eMOVEKIT is a complete system with all necessary components for the drive and control of linear motion in mobile equipment with a 24V power source. An Ewellix electric actuator is included as well as the required connectors, cables and mounting attachments.

Ewellix developed the eMOVEKIT due in part to the growth of electrification in the off-highway equipment industry. In some cases, electric actuators are being used in place of hydraulics because of the efficiency, power density and reliability they can provide. The company says the kit aims to help both experienced engineers as well as those who are new to electric actuators easily implement them in their machine designs by providing all necessary components. The kit can be used for prototypes and full-scale equipment builds.

Epec Presents Three New ECUs

Technology company Epec, part of Ponsse Group, presented three new electronic control units (ECU) to aid the increasing use of electronics and software in construction equipment. The company says these control units can help OEMs with the implementation of steer- and brake-by-wire systems, edge computing, advanced control systems, electrification and more.

The Epec Core Unit and SL8X Control Unit are designed for control systems requiring real-time control, functional safety and flexible interfaces. Both ECUs are equipped with various programming options including C++ and Ethernet. Connectivity for real-time data exchange is included as well as IP69K compliance to ensure reliability in harsh off-road environments.

Epec also presented the GC44 Responder unit which benefits use for centralized intelligence systems. It is a generic CANopen responder unit and designed to withstand use in harsh operating conditions.

Danfoss Adds Hydraulic Hoses and Connection System to Portfolio

Danfoss Power Solutions has introduced new hydraulic hoses as well as a system aimed at simplifying hydraulic line connections.

READ MORE: Danfoss Remains Invested in Hydraulics

The new Aeroquip by Danfoss FC250H and Weatherhead by Danfoss H250H hoses are designed to exceed SAE 100R5 performance levels; they are tested to 300,000 impulse cycles.

Both hoses feature a two-braid design which helps to reduce their weight and improve flexibility compared to three-braid hoses. According to Danfoss, the hoses weigh 20% less than conventional three-braid versions which helps to reduce overall vehicle weight for improvements in fuel efficiency.

The bend radius of the hoses is half that of the 100R5 requirement. They also feature a 25% tighter bend radius and 15% smaller outer diameter than the 100R5 maximum, making it easier to route the hoses and use them in the tighter installation spaces common to today's construction equipment.

Installation is aided as well by the use of a universal flat crimp fitting. This provides a smaller profile for reduced installation complexity and saves up to 70% over the cost of bubble crimp tooling states Danfoss in its press release announcing the launch of the hoses.

Danfoss also launched its multiplate system to the North American market at IFPE. A configurable coupling system, it helps users to connect and disconnect up to six hydraulic lines simultaneously fitted with Danfoss flat face quick-disconnect couplings. This can be done in a single movement, increasing the speed at which assembly, maintenance and attachment changeout can occur.

The multiplate system features a patented internal mechanism capable of withstanding heavy-duty cycles yet lowering the force required for connections by 40%. It can be configured to make connections under pressure, supporting manual connection up to 350 bar.

Safe and reliable connections are assured by eliminating the chance of crossed lines and contamination. Per Danfoss, there is an integrated sealing band between the fixed and movable plates which prevents dirt and dust ingress during operation. A fixed plate with a dust cap which automatically closes provides protection for female couplings during disconnection.