Download this article in .PDF format

Hydraulic systems can use either of two methods of load control: the energy-loss method, in which flow to the actuator is set by valving, or the volume-control method, in which the stroke of a variable-displacement pump sets the rate at which fluid flows to the actuator. Although systems using variable-displacement pumps inherently are more efficient, they are more costly and cannot react as quickly as systems using servo or proportional valves operating from a constant pressure source.

Most industrial hydraulic systems are designed using the energy loss method. Such systems cost less to build and are more responsive because system energy is immediately available. But because of the inherent poor efficiency of these systems, energy lost as heat can exceed that of the mechanical power produced by the system. For example, even well-designed electrohydraulic servovalve or proportional valve systems may convert 60% to 80% of input horsepower to heat. Well-designed non-servo systems can produce heat losses of only 20% to 30%.

Some hydraulic system heat is desirable to bring fluid up to operating temperature. Cold hydraulic oil has a higher viscosity than warm oil. So maintaining an operating temperature of 100° F would cause sluggish operation and excessive pressure drop in a system designed to operate at 140° F. When a system begins operation on a cold winter morning, for example, the oil should be allowed to warm until it reaches a temperature where heat is generated at the same rate as system heat radiating into the atmosphere or other cooling medium.

If heat generation exceeds the radiation rate, the excess heat can cook the oil, start oil decomposition, form varnish on system component surfaces, and begin to deteriorate system seals. Excess heat sooner or later spells trouble for any hydraulic system. Too much heat breaks down oil, damages seals and bearings, and increases wear on pumps and other components. The solution to these problems is the inclusion of a properly sized heat exchanger as a component of the system.

Thermodynamics

Heat is a form of energy that migrates from one region to another when a temperature difference (gradient) exists between the regions. Heat naturally flows from the hotter region to the cooler one. The rate of heat transfer is important in determining how much can be removed from a system within a given time frame. As long as it has a higher heat transfer rate, a physically smaller heat exchanger can remove heat from a system faster than one that is much larger.

The defining equation for any heat exchanger is:

q = U X A X ΔT

where:

q is the heat transfer rate, BTU/hr,

U is the overall heat transfer coefficient, BTU/hr-ft2-° F,

A is the heat transfer surface area, ft2, and

ΔT is the fluid temperature difference, °F.

These three factors take varying forms depending on the particular design of heat exchanger and the application involved. Inspecting the equation reveals that increasing any factor on the right increases heat transfer rate in direct proportion. Doubling the surface area in contact with the heated fluid doubles the heat transfer rate. Increasing temperature difference between the hydraulic oil and the coolant by 50% increases the heat transfer rate by 50%.

Heat dissipates from a fluid system through natural and forced convection. Natural convection occurs as heat moves from system components into the surrounding atmosphere because of the temperature gradient. In smaller hydraulic systems, temperatures generally are lower than in larger systems, and heat transfer from the oil to tubing and other component surfaces often provides sufficient cooling.

But if natural convection cannot remove enough generated heat, a heat exchanger must be installed to control system temperature. The heat exchanger uses forced convection to remove heat. Another mode of heat transmission, radiation, may often occur, but its effect is small and usually can be ignored. Generally, a heat exchanger is necessary for a hydraulic system if:

- a specific oil temperature limitation is necessary to stabilize oil viscosity

- cycle dwell time is a major portion of the total duty cycle, especially in systems with fixed-displacement pumps, and

- there is a history of problems from hot oil, or shortened oil or seal life.

Heat-transfer mechanisms

The heat transfer coefficient, U, is composed of several mechanisms. The first is the convective heat transfer from the hot fluid to the wall separating it from the cold fluid or air. This can be called the hot fluid thermal resistance, which depends primarily on physical and thermal fluid properties. Turbulent flow and high velocity improve heat the transfer rate.

The second heat transfer mechanism is thermal conductance through the tube wall. Most heat exchanger tubes are built from copper or aluminum alloys or similar materials that exhibit high thermal conductivity.

The third mechanism is the convection of heat from the tube wall to the cooler fluid in the tube. This mechanism acts in much the same manner as the hot fluid thermal resistance. Use of multi-pass flow patterns takes advantage of the fluid velocity and turbulence for increased U values.

Other conditions that influence heat transfer rates are fouling factors that may occur on both sides of the tubes over a period of time. When a flowing fluid system deposits material or scale on boundary walls, they become fouled. This layer of scale:

- acts as an insulator

- increases effective fluid-film thickness, and

- reduces fluid velocity distribution near the tube wall.

As the scale thickens, heat transfer rate decreases accordingly. Mechanical or chemical cleaning, or both, may be necessary to remove the scale when excessive deposits degrade heat exchanger efficiency.

Tube-pass configurations

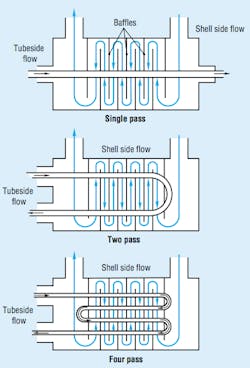

Heat exchangers are available in 1-, 2-, and 4-pass configurations, Figure 1. These multiple passes result from dividers in the bonnets that mate with segmenting bars on the tube sheets to initially force the cooling medium (water) through only a fraction of the tubes. This causes the water to flow one, two, or four times the length of the heat exchanger before it leaves the outlet.

The equation at left applies to shell-and-tube heat exchangers, but several factors expand and complicate the basic equation, so they will not be addressed here. Some basic rules still do apply: the larger the area, A, the greater the flow, q. This is logical because with a given heat transfer coefficient, larger heat exchangers can transfer more heat. The flow pattern through the heat exchanger can have a great influence on the heat removal rate.

Fluid can flow in laminar, transitional, and turbulent modes. When flow is laminar and at low velocities in a tube, there is little or no fluid movement immediately next to the tube wall. This layer of stagnant fluid hinders heat transfer and acts as insulation. Faster, turbulent flow has no smooth velocity gradient. The jumbled, tumbled flow pattern can disrupt much of the stationary fluid film. Built-in obstructions to flow, called turbulators, disrupt laminar flow, thereby improving heat transfer. Although these obstructions to flow increase pressure drop through the heat exchanger, the improvement in heat transfer more than compensates for the higher pressure drop.

Water cooling

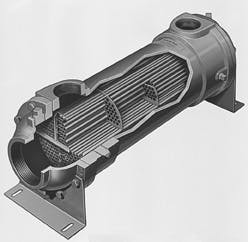

Shell-and-tube heat exchangers, Figure 2, have an outer flanged shell with end bonnets appropriately sealed to the shell ends. A precise pattern of tubing within the shell runs the length of the shell and terminates in end plates. Tube ends are fastened to the end plates, which seal each end of the shell. Cool water flows inside the tubes, and hot hydraulic oil flows around the tubes within the shell.

These heat exchangers are made of red brass, copper, cast iron, admiralty brass, stainless steel, aluminum, or other special metals. The tubes that make up the tube bundle, or core, are arranged in geometric tube bundle patterns (square or triangular centerline spacing when viewed from the tube ends) to help promote turbulent flow. The tubes run through a number of baffle plates that provide structural rigidity and create a maze through which the hot fluid must flow. This flow pattern enhances heat transfer by forcing the hot fluid to flow perpendicular to the tubes and promoting laminar flow. Many tube bundles for hydraulic applications are permanently sealed in the shell. Models with removable tube bundles are available but are more expensive and have different sealing conditions at the shell ends.

Air cooling

When the air sink is the choice to receive waste heat, a familiar heat exchanger like that shown in Figure 3 is used. Even though it radiates heat only to a small degree, it is often called a radiator instead of a convector. It convects heat and uses the same equation examined earlier to describe performance.

Hot oil passes through the tubes of these heat exchangers, and turbulators help break up laminar flow to promote efficient heat transfer from the fluid to the tube wall. The tube metals also have high thermal conductivity.

Stagnant air around tube exteriors presents a problem in the effort to increase heat transfer. Still air is a poor conductor and has a high thermal resistance that limits heat transfer. As might be supposed, increasing air flow over the tubes helps decrease this thermal resistance. The amount of decrease again depends on whether the air flow is laminar or turbulent. In either case, the air still inhibits heat transfer because it is not as good a conductor of heat as water or oil.

As with shell-and-tube heat exchangers, increasing the heat transfer surface area increases heat transfer capability. Fins, physically fastened to the tubes, increase surface area and, as an added benefit, help break up laminar air flow.

Considerations that help determine heat exchanger core configurations are:

- oval tubes promote turbulent flow at lower flow rates than round tubes do

- round tubes give higher flow rates and lower pressure drops than with oval tubes

- materials generally are admiralty brass, brass, aluminum, or steel. Choice can depend upon structural needs or service environment, and

- fins vary in heat transfer capability and cleanability. Fin types are flat plate, humped, and louvered, ranked in order of increasing ability to generate turbulent flow and in decreasing order of cleanability.

Newer designs

Shell-and-tube heat exchangers have been the mainstay of industry for well over 50 years. Recently, however, new designs have been developed to increase effectiveness, provide equivalent heat transfer surface in a smaller envelope, yet reduce cost.

The extended-surface design adds many fins to the external sides of tubes. These fins provide more surface area and improve the heat transfer coefficient, thereby reducing the size of the heat exchanger over standard shell-and-tube versions. However, because of the greater internal heat-transfer surface area, pressure drop is correspondingly greater than in the older versions.

The extended-surface design shell-and-tube heat exchanger is also available with a spring-loaded pressure-surge protector. If system pressure surges, a bypass valve opens to protect the tubes from damage due to excess pressure.

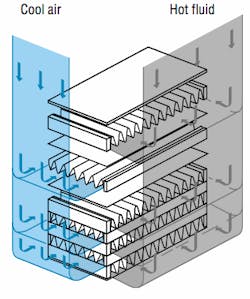

Another newer heat exchanger design is the brazed-plate type, Figure 4. The heat-transfer surface consists of a series of stainless-steel plates, each stamped with a corrugated pattern designed for a combination of high strength, efficiency, and fouling resistance. The number and design of the plates vary according to the desired heat-transfer capacity. The plates are stacked together with thin sheets of copper or nickel between each plate. The plate pack, end plates, and connections are brazed together in a vacuum furnace to secure the plates together at the edges and at all contact points. Inlet and outlet connections are available in a number of different styles.

The brazed-plate heat exchanger is compact, rugged, and provides high heat transfer capability. Its heat-transfer surface area is concentrated in a very small volume. The corrugations in the plates induce turbulent flow to increase heat transfer and reduce fouling. A brazed-plate heat exchanger holds about one-eighth the liquid volume of a thermally comparable shell-and-tube counterpart.

Normally the hot and the cold fluids make only one pass through this exchanger. The incoming fluids are directed through alternate parallel channels created by the stacked channel plates. The single pass through the unit means the flow passage is as long as the heat exchanger is high. This short flow path offsets any pressure drop which is caused by the turbulation.

The same heat-transfer principles govern performance of brazed-plate heat exchangers. Stainless steel construction of the brazed-plate design allows flow velocities as high as 20 ft/sec. These higher velocities, coupled with turbulent flow, provide heat-transfer rates of three to five times those of shell-and-tube heat exchangers. The higher heat transfer rate means less area is required for a given capacity. Tests show the brazed-plate design can handle particles up to about 0.040 in. without plugging. A strainer should be used if larger particles may be encountered. Because of their construction, these heat exchangers must be cleaned chemically rather than mechanically.

The plate-fin heat exchanger is characterized by its compact, light-weight, efficient design. It provides significantly more cooling per cubic inch than the the other designs described earlier. Plate-fin heat exchangers consist of finned chambers separated by flat plates and route fluids through alternating hot and cold passages. Heat is transferred via fins in the passageways, through the separator plate, and into the cold fluid via another set of fins, Figure 5. The basic construction consists of alternate layers of fins and plates brazed together to provide a honeycomb structure that offers high resistance to vibration and shock. Because it is so efficient, lightweight, and has high structural integrity, it is frequently used in military and aviation hydraulic applications.

Another reason for using this type of heat exchanger is that design flexibility is much greater with the plate-fin type. Finned passage sizes are easily varied by changing fin heights. The number and width of finned passages are also easily varied as is the fin density. A plate-fin heat exchanger size can be customized to fit a particular envelope.

The plate-fin heat exchanger usually is fabricated from aluminum, but regardless of the materials of construction, the core is furnace brazed in a controlled atmosphere or high vacuum. Because plate-fin heat exchangers require more precise manufacturing, they are usually more expensive than the other heat exchangers discussed earlier.

Application considerations

When determining the heat exchanger requirements of a hydraulic system, consider how much heat the system generates and what temperatures the oil and system components can tolerate. Determining hydraulic cooling needs can be confusing because heat generation may vary as a machine progresses through different cycles. Also, ambient temperatures may shift or heat generation may increase over time.

The first step in determining heat transfer requirements of a system is to know the temperature limits of the system fluid and components. This information is available from the respective suppliers.

Next, estimate total system heat output before building the system. To arrive at this figure, many designers use the nominal percentage of input horsepower method. Using this method, heat is estimated to be a percentage of total system inefficiency, based on individual component inefficiencies, plumbing surface area, and past experience. The total of these percentages is multiplied by the input hp and converted to BTU/min, BTU/hr, or kW.

For example, a 300-hp hydraulic system is assigned an efficiency rating of 70% or 210 hp. The remaining 30%, 90 hp, is lost as heat. The 90 hp converts to 3,820 BTU/min or 229,200 BTU/hr, or 67.14 kW. After the system is built, heat rejection is determined by measuring the fluid temperature rise during system operation over a period of time. Temperature rise per unit of time, along with system capacity, determine heat input.

To reduce their exposure to high pressures, heat exchangers should be installed in the tank return line to reduce their need to withstand high pressures. A bypass valve protects them from high pressure surges, such as those commonly experienced during cold starts. Bypass valves also can be specified based on fluid temperature. In this manner, fluid bypasses the heat exchanger until warming to a predetermined temperature, which closes the bypass valve and routes fluid through the heat exchanger. An alternate piping method uses a separate circuit from the reservoir with a small pump to drive the oil through the heat exchanger. Filters often are incorporated into these side circuits - or kidney loops, as they are sometimes called.

Oil-to-air heat exchangers are most commonly used on mobile applications. Engine coolant is available for oil cooling, but the heat must eventually be removed into ambient air through the radiator. Some installations use a separate section of the radiator in front of the engine-driven fan for oil cooling.

When considering application and sizing of heat exchangers, the steady-state temperature of the hydraulic fluid and the time it takes to arrive at that temperature must be used. A heat exchanger manufacturer can assist with application and selection. When contacting the representative, be prepared to provide the following:

- oil heat load in BTU/min

- oil flow in gpm

- maximum oil temperature

- ambient air temperature during system operation

- environmental contaminants that can affect the system, and

- maximum allowable pressure drop.

If the heat exchanger is liquid cooled, the supplier will also need to know the cooling water inlet temperature and flow rate. Most manufacturers' literature includes examples, steps, and simplified equations to help size heat exchangers properly.

Now the heat exchanger choice can be made: will it be an air- or water-cooled version? Generally, air-cooled heat exchangers are more expensive than water-cooled ones on a per-unit basis, because on other than mobile applications, the air-cooled version requires a fan/motor package. But there are more considerations:

- electric costs to run the fan

- costs to purchase water, pump it, or perhaps treat it before use or after discharge

- fan noise and hot air exhaust

- clogged cooling surfaces if debris becomes airborne, and

- vibration mounts and flexible piping.

A properly sized and applied heat exchanger can save time, money, and repair costs. Many fluid power systems should not operate without one.