Most engineering efforts focus on ways to design and manufacture products that satisfy application requirements as inexpensively as possible. But you can make a satisfactory design better by making it more reliable and easier to maintain - and without spending a lot of money. How? Simply by following simple tips and recommendations offered by manufacturers. These fundamentals concern bending, alignment, motion, and similar basic guidelines.

Application basics

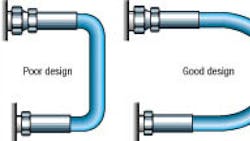

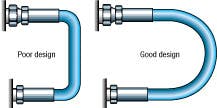

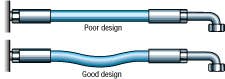

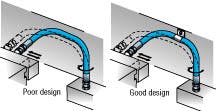

Most manufacturers offer hose that can be bent to a tighter radius than that published in industry standards. Still, bending hose to a smaller radius than recommended should be avoided to avoid shortening service life. Therefore, route hose in a manner that provides ample bend radius.

Providing protection

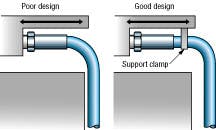

To help prevent abrasion, use clamps to secure hose in place and keep it from rubbing against adjacent surfaces. The clamp should have a snug fit around the hose to prevent movement, but not be tight enough to damage the hose by compressing it. Be sure the hose is slack on both sides of the clamp to compensate for contraction and expansion.

Additional protection can be provided by sleeves. Metal sleeves resemble springs that protect the hose from being crushed. Fabric sleeves help keep abrasive particles away from hoses, and both types can serve the added function of nestling multiple hoses into a compact bundle.

Some types of sleeves must be installed from one unconnected end of the hose and slid along its length. Others have a longitudinal slit to enable installing the sleeve without having to disconnect either end of the hose assembly.

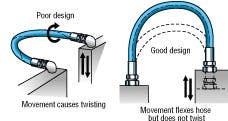

Accommodating movement

When multiple lengths of hose lie close to each other, and substantial linear motion will occur, hose carriers keep hoses neatly nestled to prevent tangling, twisting, and rubbing against each other. Depending on which particular type is specified, carriers can also isolate the hoses inside from potentially hostile conditions outside - impact from falling objects, abrasive particles, chemicals, or intermittent high temperatures.

Other important considerations

In other applications, static electricity sometimes may be discharged through the hose wall to surrounding surfaces. This is caused by conducting electrostatic charges from the fluid through the hose's metal reinforcement and cover to adjacent surfaces. Consequences can include localized burning that weakens the hose or even produces pin-size holes in the hose wall. In this case, hose with a conductive tube may be called for to conduct electrostatic charges to hose end fittings rather than through the hose.

Just as twisting can dramatically shorten hose life, so can excessive heat. Heat from external sources, such as exhaust components on mobile equipment, can quickly soften or embrittle the hose wall from the outside in. Therefore, it is important to keep hose away from external sources of heat. If this is not possible, manufacturers offer insulated protective sleeves to partially block heat transmitted to the hose.

However, heat from an internal source - the hydraulic fluid itself - also can reduce the service life of the hose. Pumping hydraulic fluid at a temperature of only about 18° F over the maximum recommended temperature for a hose can cut its expected life in half. What makes this problem even more serious is that machine operators often are unaware that fluid temperatures may exceed manufacturers recommendations - especially if the high temperatures occur only intermittently.

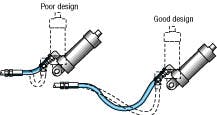

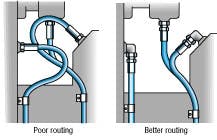

Finally, strive for neat appearance when routing hoses. This not only prevents tangling, twisting, and rubbing together (which can cause abrasive wear), but aids maintenance by making it easy to remove and re-install hose assemblies and trace circuit routing.

Use adapters sparingly because they add to the number of components in an assembly. This increases assembly time, cost, and the number of potential leak points. However, when properly applied, adapters can simplify hose assemblies that use angled fittings (such as 90° elbows) at each end. Hose-end fittings on these assemblies must be carefully oriented to prevent twisting the hose during installation. So using an angled hose coupling at one end of the hose and a straight coupling connected to an angled adapter fitting on the other eliminates the need to carefully align hose ends during assembly.

Todd Mueller is manager, hose and connector product application engineering, Gates Corp., Denver.