This file type includes high resolution graphics and schematics when applicable.

Hydraulic fluid performs multiple functions, such as power transmission, lubrication, heat transfer, and conveyance of contamination into filters. With the important roles played by fluids, proper fluid selection is critical in maximizing performance and life of hydraulic pumps, motors, and other components. To make the right choice, a variety of fluid properties must be considered, along with other factors such as operating parameters, system requirements, environmental conditions, and regulations.

How Fluids Affect Pump Performance

Hydraulic components and the hydraulic fluid work together to run the hydraulic system. Because the fluid is the medium by which power is transmitted to perform any usable work, hydraulic systems simply cannot operate without sufficient fluid. Taking its critical role into account, appropriate fluid type, viscosity, and quality are essential requirements for fluid selection.

A hydraulic system with a poorly matched fluid may operate, but it will deliver substandard performance that could ultimately lead to catastrophic failures. Improper fluid selection can cause various undesirable results, such as decreased system efficiency, lack of lubrication, short fluid and component life, corrosion, erosion, sludge and varnish formation, and excessive heat generation.

In addition to fluid properties and quality, contamination also affects system performance significantly. Contamination can generally originate from four sources: contaminated oil, built-in contamination, ingressed contamination, and internally generated contamination. Independent of the source, it can lead to decreased efficiency, component wear, and other adverse impacts. Studies indicate that more than 70% of hydraulic system failures are due to contamination and can reduce hydraulic efficiency as much as 20% before a system malfunction is recognized.

Importance of Viscosity

Various fluid properties affect the fluid’s ability to perform different functions. Viscosity, which describes a fluid’s resistance to flow, is the most important. It has a profound influence on hydrodynamic/boundary lubrication, volumetric efficiency, mechanical efficiency, cavitation, quantity of lubricants reaching lubricated parts, heat generation, and many other properties like air release, heat dissipation, and filterability.

Low-viscosity fluids provide thin film thickness, leading to boundary lubrication conditions, which can result in metal-to-metal contact and damage system components. For example, when two moving metal surfaces contact each other with inadequate lubrication, excessive wear can occur due to cold welding (Fig. 1), and damage components. Low viscosity also reduces volumetric efficiency of pumps and motors through increased internal leakages.

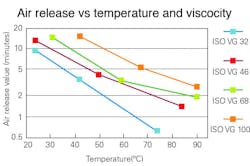

On the other hand, high viscosity, or high resistance to flow, can result in sluggish operation and decreased mechanical efficiency. Energy losses from high viscosity can result in elevated fluid temperature. High viscosity can cause cavitation and poor air release properties, resulting in cavitation and aeration erosion (Fig. 2). In addition, a high-viscosity fluid may not reach areas with tight clearances, causing failures from lack of lubrication.

The rate of air release varies based on different viscosities and temperatures. At a given temperature, air is released faster with lower -viscosity fluids (Fig. 3). As the temperature increases, air is also released faster for each fluid.

Overall efficiency of hydraulic components is related to mechanical efficiency and volumetric efficiency. Mechanical efficiency is related to frictional losses and drag due to fluid viscosity, and volumetric efficiency relates to internal leakage. Both volumetric and mechanical efficiency depend on the viscosity of the fluid.

As shown in Fig. 4, volumetric efficiency increases with increased viscosity, whereas mechanical efficiency decreases. The particular range of viscosity at which overall efficiency is maximum is typically selected as the optimum range for the specific components. Viscosity recommendations should be considered for all system components, but viscosity recommendations for pumps and motors should be given prime importance.

Viscosity itself is affected by temperature, with environment temperature, operating temperature, and system design acting as contributing factors. Suitable viscosity-grade fluid needs to be selected for each application based on the operating temperatures. The fluid viscosity at operating temperature must meet the viscosity recommendations of the system components (primarily the pump). Minimum, normal, and maximum operating temperatures need to be considered for selecting the fluid viscosity grade.

Preventing Wear Extends Life

Anti-wear (AW) properties of fluids are another crucial parameter to be considered. Good AW properties are required to maximize hydraulic system performance and component life. The fluid must be properly formulated and have adequate AW additives. These additives form a thin layer on the mating surfaces and help prevent metal-to-metal contact at boundary lubrication conditions. The resulting damages due to lack of AW properties is depicted in Fig. 5.

Insufficient AW properties can lead to cold welding and scuffing in the boundary lubrication regime, resulting in removal of surface material. Anti-wear properties are essential for both rolling and sliding contact; the requirement for sliding contacts is more critical, however, as stick-and-slip type movement can occur. Even the best-machined surfaces have asperities (peaks and valleys).

When these asperities come in contact from a heavy load, they can become joined by cold welding. If the applied force is large enough to break the welding, the object suddenly moves. This causes material removal from surfaces. High AW additive reserve is recommended for severe application, thus allowing the surfaces to slide or roll over each other without any surface damage.

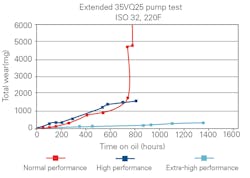

The Eaton-Vickers 35VQ25 pump test was developed to demonstrate a fluid’s ability to protect components from wear, thereby confirming long-term use in various operating conditions. The test was adopted by the American Society for Testing and Materials (ASTM) with the designation of ASTM D6973 (Standard Test Method for Indicating Wear Characteristics of Petroleum Hydraulic Fluids in a High Pressure Constant Volume Vane Pump).

More specifically, the 35VQ pump test can be used to evaluate anti-wear properties of hydraulic fluids. Higher performance fluids can dramatically reduce wear and extend the life of components (Fig. 6).

Other important properties include:

Viscosity Index (VI)—A unit-less number indicating the effect of temperature change on the kinematic viscosity of an oil. Liquids tend to become less viscous when heated. A high VI indicates a relatively small change of viscosity with temperature. High VI (multi-grade) fluids are recommended for applications operating within wide temperature ranges. In general, high VI fluids are recommended for mobile applications, as they are exposed to environmental changes and high operating temperatures.

Shear stability—This is the measure of a fluid’s resistance to shearing. The molecules of VI improvers break down to smaller molecules, causing thinning of viscosity (also known as shearing). Shear stability is the most important property of a VI improver. VI improvers with low shear stability will quickly break down, so viscosity after shear should be evaluated for systems using VI-improved fluids.

Thermal and oxidative stability—Oxidation is the chemical reaction of oxygen with oil, generating acidic byproducts. The rate of oxidation is accelerated by high temperatures, water, acids generated due to oxidation, and the presence of metal catalysts such as copper. In general, oxidation doubles for every 10° C increase in fluid temperature. Oxidation leads to increased viscosity, total acid number (TAN), generation of varnish and sludge, and darkening of fluid. The rate of oxidation can be reduced by reducing fluid temperature and using fluids formulated with high-quality base stocks, anti-oxidant additives, and thermally stable AW additives.

Hydrolytic stability—Hydrolysis is the chemical degradation of lubricants by reaction with water. Lubricant additives—especially zinc-based ones—will react with water, forming acidic byproducts. The presence of metals such as copper can act as a catalyst. Ester-type base stocks also hydrolyze in presence of water. Lubricants with good hydrolytic stability will resist hydrolysis.

Filterability—Fine filters used in hydraulic systems may exhibit premature filter plugging due to inappropriate formulations, water contamination, and fluid degradation. Measuring filterability helps to predict fluid behavior in filtration applications before use in a system.

Demulsibility—The ability to release water from a water-oil mixture. This characteristic is important for the equipment operating in humid climates, where the possibility of water contamination is high.

Corrosion inhibitors—Hydraulic fluids are generally formulated with rust and corrosion inhibitors. The rust inhibitors get deposited as thin film on the metal surfaces and enable protection from rust. The corrosion additives hinder hydrolysis and prevent formation of acidic materials, which otherwise cause corrosion. The ability of a fluid to prevent rust and corrosion can be measured by a rusting test using distilled water, salt water, and a steel specimen.

Material compatibility—Different rubber and elastomer components—including hoses, accumulator bladders, seals, and gaskets—are used in hydraulic systems and have different compositions, or recipes. Because of these varying compositions, fluids are tested for their compatibility with most commonly used elastomers to predict the life and performance with that particular fluid.

Air release—Suspended entrained air can cause many abnormalities, such as poor system efficiency, system failure through erosion (similar to cavitation), and fluid degradation through micro-dieseling. Micro-dieseling occurs when air bubbles move from a low- or negative-pressure area to a high-pressure area, get heated up due to compression, and carbonize oil at the bubble interface, resulting in carbon byproducts and oxidation. Air release characteristics have more significance in systems with relatively short residue time. An air-release test can identify the ability of a lubricant to separate entrained air.

Foaming—Foaming is a common problem for hydraulic systems. Large volumes of foam can cause overflow of reservoirs. Factors that lead to foaming are contamination, degraded fluid, air entrainment, and poor system design. Hydraulic fluid formulations contain foam inhibitors, but very high dosages can produce an adverse effect. Foaming tendency test describes the volume of foam generated immediately after the fluid is agitated and aerated. Foam stability measures the volume of foam remaining after a specific time from the stoppage of aeration.

Hydraulic Fluid Evaluation

A properly selected fluid the best balance of requirements of these properties to meet individual requirements. Many lubricants other than conventional hydraulic fluids are used in hydraulic systems, such as motor oil, automatic transmission fluids, universal tractor transmission oil, and super tractor oil universal. Some of these are formulated with petroleum-base oils, whereas others are synthetic.

Either way, hydraulic pumps generally are designed to operate with mineral-base fluids. Alternative fluids are sometimes used for applications where certain special properties are essential, perhaps even more important than hydraulic system performance.

Furthermore specific formulations or base stocks may be used to meet strict environmental or fire-resistance requirements. These include phosphate esters, polyol esters, polyether polyols, polyalkylene glycols, vegetable oil base fluids, polyalphaolefin (PAO), water glycol, and invert emulsions. For example, if fire resistance is critical, fire-resistant properties may be the most important factor.

Similarly, the focus in environmentally sensitive applications may be on toxicity and biodegradability. Still other special types of fluid are used for meeting food-grade and military requirements.

These alternative fluids will have advantages to suit the specified application, but its fundamental properties may fall short of those of petroleum-based lubricants. Therefore, hydraulic components—especially pumps and motors—may need to be de-rated to account for these adverse factors.

To determine whether a special or alternative fluid is warranted, ask some key questions:

- Does the hydraulic system operate near an ignition source or high-temperature surfaces, where fluid leakage could cause a fire?

- Are fire suppression measures potentially ineffective or impractical?

- Would a fire result in unacceptable impacts or costs?

- Are there any insurance benefits to using a fire-resistant fluid?

- Does the system work in an environmentally sensitive area, such as agriculture areas or forests, or where environmental regulations are applicable?

- Does the system need to be operated near or within waterways such as rivers, canals, or oceans or water sources, such as dams and reservoirs?

- Could leakage of oil cause damage to the environment, which could be a punishable offense?

- Does the application have any non-standard requirements such as military or aerospace?

If the answer is yes to any of these questions, the system may require a special fluid.

Anjeeve George is lead engineer – lubricants at Eaton India’s Engineering Center, Eaton Hydraulics Group Asia India, Shanghai.

This file type includes high resolution graphics and schematics when applicable.