Filler-Breather Adapter Simplifies Hookups

Reservoirs aren’t the only source of dirt and moisture contamination in hydraulic systems. These elements can also enter through actuators, especially piston rod seals on cylinders. Moreover, contaminants may be self-generated by pumps, motors, and degradation products from the fluid itself. So, even if you completely eliminate dirt and moisture from entering the hydraulic system through the reservoir, you still need to add filters within the system.

One of the most effective filtration methods is offline filtration, often referred to as a kidney loop. A kidney loop uses a circulating pump to draw hydraulic fluid from the reservoir, route it through a filter, and pump the clean fluid back into the reservoir. Heat exchangers often are incorporated into the kidney loop to control fluid temperature within prescribed range.

The problem is, installing a kidney loop or adding an auxiliary circuit to an existing system requires making sure any lines you work on are not pressurized after shutting off power. Only at this point should you open the hydraulic line you'll be tapping into, drain the fluid from the line, install a tee or other fitting, and then connect everything back up. You then have to repeat this process for the return line. However, you're still not done, because you may have to bleed air from the line, and you certainly should check for leaks.

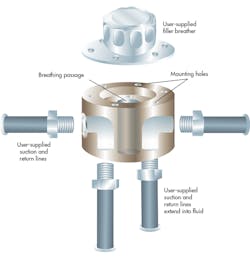

A filler-breather adapter contains connections to draw fluid from, and return fluid to, a hydraulic reservoir without the need to bleed the system. Two side ports provide auxiliary suction and return lines for convenient connection of a kidney loop or additional hydraulic pump.

To eliminate these difficulties, Tom Nell, certified fluid power engineer at Flpwr.com, developed an adapter that contains connections to draw fluid from, and return fluid to, a hydraulic reservoir. The adapter fits between the reservoir and filler breather. It comes with the hardware to mount the adapter to a standard filler-breather port on a reservoir and provides a surface for mounting a filler breather on top of it. The adapter incorporates a pair of SAE-12 ports that each lead to a ¾-in. vertical tube, which extends into the hydraulic fluid in the reservoir.

One tube can be used for suction and the other for return, simply by connecting suction and return lines to the respective port. The adapter makes it easy to tap into an existing hydraulic system to add an offline filtration circuit (kidney loop) or other auxiliary circuit. The ports also can be used to add fresh fluid to the reservoir without having to remove the filler-breather cap, which would open the reservoir to the atmosphere.