Troubleshooting Challenge: Repeated O-Ring Failures on a Cross-Port Relief

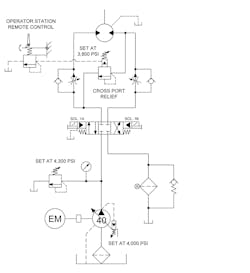

The schematic below shows a hydraulic motor system that controls the motion of a giant ladle used to move molten steel. When the directional valve is de-energized, the cross-port pilot operated relief slows the ladle as it is lowered and is controlled remotely by a technician.

The mill had problems with the O-ring between the incoming pressure of the cross-port relief and its outlet. The Buna-N O-ring kept failing. A maintenance crew replaced it with a Viton O-ring. They also changed the back-up ring that went between the O-ring and the outlet. It seemed to last somewhat longer than the Buna ring, but it too kept failing. The O-ring also would erode in one area and fail.

Maintenance checked the bore measurements of the steel block the relief screwed into and found they were well within given tolerances. So why is the O-ring repeatedly failing?

What’s the Problem?

Think you know the answer to this month’s troubleshooting problem? Then email it to [email protected] (put “Feb Troubleshooting” in the Subject line). All correct answers received by Feb. 20, 2020 will be entered in a random drawing. The winner will be mentioned in a future column.

Solution to last month’s problem:

Hose Keeps Failing on a Large 100-Ton Press

When the crane cylinder was being tested for two hours, they needed to keep the ambient temperature somewhat consistent. Oil expands approximately .005% per 10ᴼF change. This would cause the 10-in. bore cylinder to extend just short of ½-in. A 20ᴼF change would cause it to extend almost 1 in. The reverse is true; the volume can decrease if the rain caused the temperature drop. The sun shining on a cylinder can cause the rod to extend.

Robert J. Sheaf, Jr. is founder and president of CFC Industrial Training, a division of CFC Solar, which provides technical training, consulting and field services to any industry using fluid power technology. Visit www.cfcindustrialtraining.com for more information.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.