Harvester puts hydraulics to work

When is a grape harvester more than a harvester? When it also separates the grapes from their stems and sorts the grapes. A trimming tool can also be used to prune the vines.

Such is the case with grape harvesters from Pellenc SA, Pertuis, France. Pellenc manufactures multiple lines of harvester trimmers, and other equipment for owners and operators of vineyards. Pellenc’s machines are designed for maximum crop yield by taking advantage of closed-loop electrohydraulic control for propulsion, harvesting, and cleaning.

Depending on the individual model, Pellenc harvesters use an electronically controlled hydrostatic pump driving four hydraulic motors for propulsion and hydraulic steering to weave their way through vineyards. Pellenc patented its own Permanent Integral Transmission feature (called TPI), which regulates speed and distributes power between the hydrostatic drive and work functions. The TPI feature prevents skidding at all speeds in forward, reverse, and while turning.

Harvesters in Pellenc’s 8000 series are driven by either a 4- or 6-cylinder diesel engine capable of 100 or 173 hp. Maximum pressure of the hydrostatic pump is 450 bar (6525 psi). The machines typically use dual displacement hydraulic motors from Poclain Hydraulics. The dual displacement feature allows the nimble harvesters to move down each row of vines at optimum speed, yet move at higher speed when traveling to new locations.

Harvesting in progress

Grape harvesters use a variety of various harvesting heads to match the type of vineyard, ground conditions, and preferences of the growers. A condensing zone at the vegetation entry point leads an adjustable length active zone, which makes the machine adaptable to all vineyards, grape varieties, and types of trellising. The active zone is where hydraulics is used to gently, but effectively, shake the vines to release grapes.

A widening exit zone at the rear of the machine ensures that the vegetation is released gently. Pellenc experts say this is the only harvesting technique that ensures a constant distance between the left and right picking rods, guaranteeing damage-free shaking.

The harvesters are equipped with two catcher plate ramps that form a watertight base. The angle of each ramp can be adjusted, and each includes several pairs of catcher trays mounted on elastic hinges. They are closely overlapped to ensure that they slide along smoothly and do not damage the vine trunks. All metal parts of the machine that come into contact with the harvest are made of stainless steel or food-grade material. Covers are provided on all hydraulic components to protect the harvest in the event of a leak.

The fallen fruit is then conveyed via cleated belts from both sides of the machine. The conveyors can be run in reverse in case blockages occur, and their speed can be synchronized with the vehicle speed and the size of the crop.

As they are conveyed backward and upward, the grapes are cleaned by two hydraulically driven fans equipped with replaceable blade edges to chop up leaves, stems, etc. The rotational speed of the hydraulic motors driving the fans can be adjusted from the driver’s station.

Once the grapes have been cleaned, they are collected in bins, each equipped with augers to distribute the load evenly for sorting. The sorter consists of a grid-type continuous conveyor that separates the juice from grapes and whole bunches of grapes. It is located directly at the exit of the elevator conveyors. Two suction fans are located on the rear conveyor chute that completely remove all the leaves while retaining all the juice.

Automatic guidance

Pellenc’s machines come standard with its Activ’ head positioning system, which automatically keeps the harvester’s collector head centered around the row of vines. Two double-acting hydraulic cylinders carry the entire harvesting head and adjust its position left or right as needed. A closed-loop control reads position of the vine row from a pair of sensors mounted at the inlet to the harvesting head and commands the cylinders to position the carrier to within 1 mm of the vine row. A pair of indicator lights in the cab signal the driver if any correction is needed to the path of the carrier.

Competitors’ machines lean against the row for positioning, which can damage the vines, and reduce yield by allowing grapes to drop to the ground. The end result with Pellenc’s design is high yield without damaging the vines and no loss of fruit onto the ground.

Click here to see a video of Pellenc’s Model 4380 grape harvester in action, or visit www.pellenc.com for more information.

The drive for savings

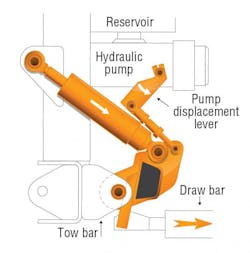

Pellenc’s solution taps into a tractor’s existing hydraulic system to give its towable version propulsion and braking. Even better, the vehicle provides traction or braking automatically. This is accomplished with Pellenc’s Auto-Torque system.