Advantages of hydraulics for motion bases

This file type includes high resolution graphics and schematics when applicable.

Motion bases for aircraft and other types of simulators demand a combination of rapid acceleration and deceleration, tight positioning control, long life, and, of course high reliability. The larger the mass that needs to be moved, the more likely the motion base will use hydraulics. Manufacturers have been able to increase the capacity of electromechanical actuators, so they present them as preferable to electrohydraulic systems.

However, many of the arguments minimize the advantages of hydraulics over electromechanical systems and exaggerate the disadvantages of hydraulics. Different motion bases have application advantages based on their particular design. Hence, the following analysis is intended for applications where it is necessary to lift and hold payloads for extended periods of time as well as accelerate and decelerate that payload while elevated. Of primary concern are motion bases designed primarily for flight simulation and similar applications.

Sizing and power requirements

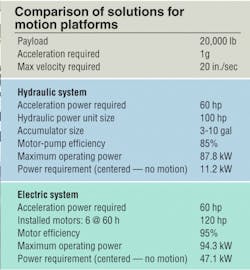

Proponents of electromechanical motion bases repeatedly claim that electrical systems consume less power than hydraulic systems do. Let’s see if this is true through an example, which is summarized in the accompanying table.

Assume we need to lift and hold a 20,000 lb payload for extended periods of time. This is a common condition for flight simulators and similar applications where accelerating and decelerating dynamics are small, but large excursions of the platform are required. Such applications typically use six linear actuators arranged in a hexapod configuration.

In this case, the hydraulic system generates heat that requires about 3.2 tons of refrigeration (38,000 btu/hr or 11.1 kW) to stabilize temperature. However, the electric unit generates heat requiring 13 tons of refrigeration (156,000 btu/hr, or 45.7 kW). This cost of heat rejection cost is rarely mentioned by those promoting electrical systems. This point is important because electrical systems are air cooled, so the generated heat migrates to the surrounding environment, typically occupied by people. Hydraulic systems reject less heat, and that heat can be dissipated in a separate room through an air- or water-cooled heat exchanger or directly to atmosphere.

This point should not be trivialized because users may have to install expensive cooling systems after they discover the higher temperature of the room housing the electric motion base. The bottom line is that electromechanical systems used in typical motion bases consume significantly more energy than electrohydraulic systems do.

Overload capacity

Both electric and hydraulic motion bases are typically designed for a specific application with a clearly defined payload. If the payload should increase, say, by 20%, an electromechanical system probably would become overloaded. Electrical systems depend on precise sizing of their motors. Suppliers rarely oversize these systems because doing so would increase cost, which would jeopardize the supplier winning the contract. If payload increases, the solution is generally to scrap the old system and order a newer, larger, and more expensive motion base.

A hydraulic system, on the other hand, can accommodate a much wider range of operating parameters. Typically, a properly designed hydraulic system can be overloaded up to 50% or more and still operate effectively. But you don’t get something for nothing; if you increase the operating pressure to handle larger payloads, then you must re-stroke the HPU’s pump to avoid overloading the motor. Doing so would sacrifice some dynamic performance to handle the larger payload. However, installing a larger motor-pump assembly could provide performance comparable to the original, even with the higher payload.

Unfortunately, this scenario is fairly common: a customer requests a system designed for an 8000 lb payload but ultimately loads the machine to 12,000 lb. An electrical system would need to be replaced, but a hydraulic systems may get by with reduced dynamic performance or a larger HPU.

Performance

Assuming equal design criteria, accelerations and velocities that can be obtained with hydraulic and electric systems are comparable. In theory, electromechanical systems should be capable of higher resolution because most of these systems use an encoder, resolver, or similar feedback transducer. In reality, though, manufacturing tolerances and design and assembly tolerances relegate the true resolution to that comparable to hydraulic systems. Digital accuracy relative to computer programming and theoretical computation can be far different from the actual accuracy once machining and fabrication tolerances are taken into account. Hence, hydraulic and electric systems accuracies are comparable.

Durability and reliability

Hydraulic motion bases have proven to be far more durable than their electrical counterparts. Many hydraulic motion bases have been in operation for more than 60 years with virtually the same hardware in place. Control and computer systems have changed and been upgraded, but the physical components are original or as original.

Other than servo and proportional valves, essentially the only moving parts in each actuator is the piston, rod, and bearings. Developments in valves have made them reliable and durable — with operational lives exceeding 30 years in most instances.

Electric motion systems have been in operation for perhaps 15 years. During that time, several have been replaced with hydraulic systems for many dead weight bearing applications. Current designs use either lead screw, ball screw or roller screw mechanisms for linear motion. All of these contain a multitude of components to convert rotational motion of an electric motor to linear motion. Planetary rollers, roller balls, and the sliding motion of lead screws all require generous amounts of lubrication.

Installation

Electromechanical motion bases require high voltage transmitted to their actuators. Special precautions need to be taken to ensure such systems are safe and meet national and code requirements. Hydraulic systems, however, only require high voltage service at a remote HPU. It is common for the hydraulic HPU to be located in a room with limited access. Hence, only low control voltages are required directly at the motion base.

Hydraulic systems require pressurized hoses routed to each of the actuators under servovalve control. Typically system pressures run from 1000 to 1500 psig. These pressures are easily and safely handled by two-wire-braid hoses commonly rated for working pressures to 3000 psig and burst pressures well above that. Leaks are virtually eliminated by using SAE O-ring, JIC, and other modern fitting configurations. And if environmental issues are a concern, any of several “environmentally friendly,” or even food grade hydraulic fluids can be used.

Complexity

Hydraulic systems are quite simple: actuators, servovalves, controller and computer. Hydraulic actuators are designed to absorb the total system energy in the event of worst case, runaway conditions. This is accomplished by using built-in cushions at either end of the actuator stroke. This common design feature is built into the cylinder to protect against all control, electrical, and hydraulic failures. Essentially, when any condition of failure occurs, the cushions protect both the motion base and the payload from damage.

Electrical systems, on the other hand, typically rely on a combination of switches and control logic to protect the system. Many electrical systems rely on a braking system to violently stop the motion. Although these can be effective in their implementation, programming and additional complexity elevates installed cost and potential for damage to either the motion base or its payload.

Maintenance

Hydraulic systems typically require maintenance approximately every 1000 hr of operation. This usually amounts to checking and replacing filters, taking fluid samples, general maintenance, and running diagnostic tests to ensure everything is adjusted and working properly.

Electromechanical systems, on the other hand, typically require lubrication about every 80 hr of operation, along with checking of power wiring and a multitude of limit switches, control logic verification, and encoder or resolver operational checks. Reliability depends on proper operation of a serial combination of components. Failure of one component causes all subsequent components in a functional chain to fail — the end result being downtime of the entire machine.

Noise

Hydraulic cylinders used in the motion base are quiet, generating levels less than 50 dBA. In most applications, any sound emanating from the cylinders is masked by ambient noise. The HPU can generate substantial noise, but it is usually located in a separate room or enclosure away from the motion base. This presents two advantages: noise can easily be isolated from the simulator, and heat-generating components are located away from the simulator. Another advantage is that most maintenance can be conducted in one convenient location — much of it with the motion base running.

Electric motion base systems can be noisy due to the many small, fast-moving parts in the actuators. They generate a loud rushing sound that is distinct and may or may be heard in the enclosure mounted on the motion base. This issue is especially important for flight simulators.

Apples to apples

Proponents of electromechanical systems often point to hydraulics as antiquated technology that is dirty and imprecise. However, this misrepresentation compares highly engineered electromechanical systems to low tech hydraulic systems slapped together in a workshop by someone with only a cursory knowledge of hydraulics and closed-loop control.

Electrohydraulic motion bases must use high quality components, fittings, materials, fluid, and control systems. The cost of common hydraulic cylinder; might be $60.00, whereas a well made cylinder of equal size and capacity with integral position feedback might run more than $1000.00. Similarly, the fittings and connections for servo quality systems commonly use JIC and SAE connections to prevent leakage — and they should never use pipe fittings.

Safety

Depending on the design concept, hydraulic systems are inherently safe, particularly when emergency-stop conditions occur. Hydraulic systems can be designed to either lock in place gently settle during E-stops and power outages. This is accomplished by either eliminating the command to the servovalve, providing a control voltage to the servovalve, or using a separate abort valve.

Electromechanical systems, on the other hand, are typically designed to lock in position when an E-stop command is initiated. Battery backup schemes can be used to provide slow settling of electromechanical systems, but at substantial additional cost and complexity of the control system logic. Otherwise signal failure can result in an immediate retraction collapse of the actuators.

The author is president of Sarnicola Simulation Systems Inc., Conklin, N. Y., and has more than 25 years experience designing and building both electromechanical and electrohydraulic motion bases. For more information, call him at (607) 724-4021, email [email protected], or visit www.

sarnicola.com.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Leaders relevant to this article: