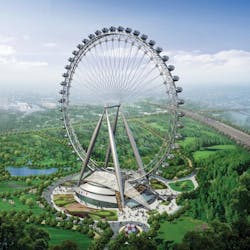

If you’ll be watching the Summer Olympics, no doubt you’ll see shots of the Great Observation Wheel of Beijing. With a diameter of 198 m and maximum height of 208 m, how could the cameras miss it? The new Ferris wheel in China’s capital city will be the world’s largest — by far. It will be able to handle 5760 passengers per hour and take them high into the air to enjoy the view across Beijing. The wheel is nearly half-again as high as the UK’s London eye, which tops out at 135 m.

Like the London Eye, the Great Observation Wheel of Beijing deviates from the conventional design of Ferris wheels, which use a drive to rotate the wheel from its center axis. The new Great Wheels, as they have been dubbed, are so large that it is not practical to drive them from their center axis. Instead, drives located at their circumference produce rotation.

The Great Wheels of London and Beijing were designed and built by Great Wheel Corp., Dubai, with control and drive solutions designed and supplied by Bosch Rexroth, Lohr, Germany and Boxtel, Netherlands. As the exclusive partner for Great Wheel Corp., Bosch Rexroth has also developed drive and control systems for many other Great Wheels, including the Great Wheel in Berlin, due to open in 2009.

Beijing’s wheel carry 48 enclosed cabins, each offering space for 40 passengers. Some simple math reveals that the wheel can carry up to 1920 passengers at a time. With a travel speed of 3 rev/hr, it can accommodate up to 5760 passengers per hour.

The driving force

No parameters based on experience are available for Ferris wheels in this size, only approximate figures extrapolated from the London Eye. Bosch Rexroth was responsible for the automation of the London Eye, but initial calculations quickly showed that the drive technology needed for Beijing would have to be significantly more powerful to produce the required performance.

The drive must have enough power to accelerate the wheel from standstill under the least favorable load condition, which would occur if only the cabins in the lower half were occupied. Bosch Rexroth engineers also had to account for force from wind speeds of up to 49 km/hr in their calculations, which they performed using simulation programs they developed. If the wind direction is parallel to the wheel, the drive system must have sufficient reserves to compensate for the braking and acceleration effect. The result is a primary drive for Beijing’s Wheel that can develop a drive force of 900 kN.

Multiple benefits from hydraulics

The advantages of hydraulics are obvious for this application. Hydraulics combines extremely high power density with low maintenance requirements and produces smooth, slow motion with low heat generation. To arrive at the optimum method of power transmission, Bosch Rexroth project specialists evaluated different concepts, such as piston drives, gears, and drive wheels based on economy, degree of wear, and safety before arriving at a solution using hydraulics.

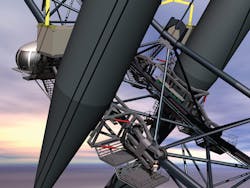

The Beijing wheel uses four drive units, each with two hydraulic drive modules, one of which is redundant. Each drive module contains a hydraulic power unit (HPU) feeding four hydraulic motors — a total of 32 motors. Each motor powers a planetary gear speed reducer, which in turn, drives a rubber tire against the circumferential rim of the wheel.

Bosch Rexroth used a similar wheel drive concept for the London Eye. However, to implement this technology economically into the Great Wheel in Beijing required wheels with a higher coefficient of friction. A hydraulic cylinder forces each pair of wheels against opposing sides of the wheel’s circumferential rim. The opposing forces produce zero net force against the rim, and the applied force from the cylinder ensures that enough friction exists to prevent the tire from slipping on the rim.

Each HPU uses variable-displacement axial-piston pumps to supply only the flow as needed to rotate the wheel at the speed required. This feature not only produces smooth operation, but provides substantial energy conservation. Another energy saving feature is that the wheel does not start and stop for loading — which would’ve required substantial power to accelerate and decelerate such a massive load. Instead, the loading platform moves at the same speed as the peripheral speed of the wheel — slightly less than 2 km/hr.

If one hydraulic drive module would fail, the redundant module within the drive has sufficient power to make up the difference in power loss. Even if an entire drive unit fails completely, the power of the other three drive modules is enough to ensure safe operation. In the event of a complete loss of electrical power, a pair of diesel-powered generators would provide electrical power to allow unloading all passengers.

Adjustable control

The hydraulic control supplies all motors within an assembly group with the same flow, a simple means of synchronizing the torque at the respective wheels, which is important for low wear and smooth motion. A higherorder control system coordinates the electrically adjustable stroke of the axial-piston pumps to ensure that all wheels turn in unison.

In addition, an auxiliary function within the hydraulics regulates the force of the cylinders acting on the tires pressing against the wheel rim. In rain and humid conditions, pressure to the cylinders is increased to prevent the wheels from slipping against the wheel rim. The electronic control monitors hydraulic pressure to the cylinders and piston rod stroke, which is accomplished using Bosch Rexroth’s CIMS linear displacement transducer integrated into each cylinder.

Automated boarding

A fully automated boarding system ensures that passengers can enter and exit the gondolas without having to stop the wheel. This is accomplished with driverless electric feeder vehicles on either side of the wheel in the ground station. Two rail circuits take the feeder vehicles alongside the wheel gondolas. Once the gondola’s doors open, passengers will have 40 seconds to exit the gondola on the one side while new passengers enter from the other side. For safety, a staff member will supervise the process in each gondola. At a defined point, the transfer is ended and the doors close.

A higher-order control system synchronizes the feeder vehicles (which are driven by Bosch Rexroth’s IndraDrive frequency converters) with the gondolas and monitors the entire process.

In addition to the project planning, delivery and commissioning of the control and drive technology, Bosch Rexroth is also responsible for the entire maintenance of the wheel. Bosch Rexroth basing this work on processes employed in the aerospace industry. After 16 hr of operation, the maintenance staff has 8 hr to perform all maintenance operations. Here, the visual inspection of the wheel’s structural elements is a major operation.

For more information, visit www.greatwheel.com. For more information about Bosch Rexroth drives, controls, and capabilities, visit www.boschrexroth-us.com.