Versatile Vane Motor Produces Virtually Constant Torque

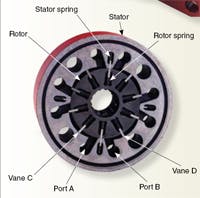

For example, as the vane marked C is in the middle of its work cycle (moving outward), the vane marked D is near the end of its work cycle (moving inward). Each rotor vane works once per cavity per revolution, so a four-cavity, 10-rotor vane motor would have 40 power strokes per revolution. The result: nearly constant vane extension — therefore, the output approaches constant torque, regardless of radial location.

The motor’s torque curves are virtually flat — with starting and stall torque equal to 90 to 94% of theoretical. Operation is smooth from less than 10 rpm to 2000 rpm and higher. As the rotor vanes approach the stator vanes, radii machined on the crossing edges at both vanes’ tips come into contact, allowing each vane to slide past the other.

Specification summary

Four series (15, 37, 57, and 125) cover range of 21 displacements from 5 to 250 in.3/rev that produce continuous torque from 183 to 13,714 lb-ft. Pressure ratings for all standard models: 3000 psi continuous; 3500 psi intermittent. (High-performance models: 4500 psi continuous; 5000 psi intermittent.) Speed range: 2000 rpm continuous (smallest model) to 300 rpm continuous (largest model).

Make contact: Rineer Hydraulics, Inc.San Antonio, TX 78216Phone: 210/341-6333 www.rineer.com

About the Author

Richard Schneider

Contributing Editor

Contributing Editor, has been affiliated with Hydraulics & Pneumatics for more than 30 years and served as chief editor from 1987 through 2000. He received a BSME from Cornell University and also completed additional courses at the Milwaukee School of Engineering. His diverse background in industry includes ten years with a fluid power distributor and a variety of other professional positions. He has also been active with the National Fluid Power Association and Fluid Power Society.

Leaders relevant to this article: