The gain can be calculated with the VCMM equation — an effort that is quite beneficial before assembling any hardware. However, the calculated value will make more sense if we assume the hardware exists, and we proceed to measure the speed gain. The speed gain block will be set up as in Figure 3. The system to be tested contains all the components that will produce output speed with and input voltage. This defines the physical limits of speed gain.

The test is set up, first, by mounting and plumbing all the hardware and wiring all the electronic parts accordingly. With hydraulic power applied, the supply pressure is set to the desired value. The test can be conducted using several different supply pressures. However, we will assume that just one pressure will be studied for our tentative setup.

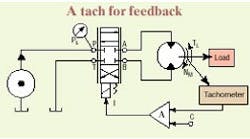

Next, a method must be arranged so that the mechanical load on the motor shaft can be adjusted to each of several desired values. A common practice is to use a hydraulic pump as a load, and then use an adjustable load valve to vary its pressure — which behaves as a variable load torque on the shaft. A torque transducer is commonly used to ensure that the load is correctly set, and a tachometer measures the output shaft speed. So, in the end, we are going to use all of the hardware of the closed-loop system, but we will be testing without the loop closed. That is, the tachometer output signal will not be connected to the feedback input on the servo or proportional amplifier. Not surprisingly, this is referred to as an open-loop test.

The test is conducted with the supply pressure set to the desired value, the load is set to zero or near zero, then the command voltage is set to zero. The command voltage is then increased in convenient increments to a value that results in maximum desired motor speed. While the command signal is high, the load is increased, say, to 33% of maximum torque. Then the command signal is lowered in convenient increments to zero.