Hydraulic pump and motor combinations have always had significant advantages over electrical or mechanical power transmission. But one of the biggest raps against hydraulics has been low efficiency. According to Sanderson Engine Development LLC (SED), Upton, Mass., a swashplate or bent-axis hydraulic pump-motor combination has an efficiency of only 60%. However, a new, more-efficient means of converting rotary motion to linear — and vice versa — is the Sanderson mechanism, which could lead to hydraulic pumps and motors of unprecedented efficiency.

A.E. Sanderson, VP of R&D, co-inventor with brother Robert A. Sanderson, VP of engineering, says the biggest energy loss of a hydraulic motor normally occurs because of the unfavorable leverages developed in transferring power from an axial thrust to a rotating moment. "This motion resembles trying to run a worm gear backwards. At mid stroke, a straight-line push of 100 lb along the axis of the piston is multiplied by the tangent of the swash plate angle to determine the force directed along the circumference of the swash plate. This component is turned into useful output torque, but only about 25 lb is available to drive the load. The remaining 75% of the force is wasted, increasing friction, and creating a parasitic load on joints and parts."

A different approach

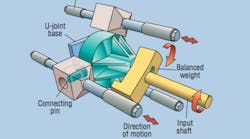

The new Sanderson mechanism avoids this limitation with a rocker arm solution, which reportedly can be applied to any design currently using a crankshaft, bent axis, swash plate, or a wobble plate. Explains Sanderson, "The principle of the mechanism is similar to a 90° rocker arm used in overhead-valve engines: a rotating crank displaces a push rod, which applies force and motion to one end of a rocker arm. This causes the rocker arm to pivot, thereby transmitting the force and motion at its opposite end to a valve stem."

Sanderson continues, "The 90° rocker arm can be connected to ground with a simple cross universal joint to give the rocker arm an additional degree of motion. The U-joint allows one end of the rocker arm to track the circular movement of the output crank with a suitable journal bearing, while the other end of the rocker arm is simultaneously constrained to follow a straight-line path and to reciprocate.

"If you imagine such a rocker arm mounted on a conventional U-joint, with one arm straight out, this arm can trace any path on the surface of a sphere within a solid angle of at least 30°. As this action takes place, because the U-joint cannot rotate, the other arm can only nod back and forth in a single plane. The motion of this arm is affected only by a single component of the motion of the first arm. Therefore, if the first arm is moving in a circle, then the motion of the second arm is a simple sine wave."

Additional benefits

Other substantial benefits exist, points out Sanderson. "The rocker arm works equally well in both directions. At mid-stroke, a push of 100 lb from the piston side can result in a 100-lb push in the circumferential direction along the path of the output crank. Virtually all the push of the piston converts directly to output torque. There is no need for side force on the cylinder walls to support either of these forces. Indeed, the side force of a Sanderson mechanism is normally zero, which eliminates a major source of friction in a crank mechanism."

The rocker arm works just as well in the reverse direction, says Sanderson. "Circumferential force of 100 lb converts to 100 lb of force to drive a piston. Again, the losses of a rocker arm and of piston-cylinder friction are minute. Total frictional load is negligible compared to the frictional losses of crankshafts, swash plates, wobble plates, and bent-shaft mechanisms."

According to Sanderson, SED now has hydraulic motors and pumps that exhibit efficiencies in the mid-nineties. This creates immediate applications in fields where the convenience of hydraulics has been outweighed by the need for energy conservation, such as windmills or automobile drive trains.

He offers that electric generators could be removed from the top of wind power generators and replaced by a hydraulic pump at the top for a lighter weight, smaller, and less expensive tower construction. Hydraulic motors on the ground could drive the generator with high efficiency and variable speed, if necessary.

Variable displacement

Variable displacement is accomplished with an optional stroke control, able to go from full stroke to zero, or even reverse stroke, with a single point control that affects all pistons and cylinders equally.

Sanderson explains, "In automotive applications, the hydraulic drive has been used in the past with notable results, including continuously variable speed drives and energy recapture. However, overall efficiency of only about 60% created a serious handicap. The advent of the Sanderson mechanism changes all that. Because overall efficiencies in the mid-nineties exceed that of a conventional drive train, a reconsideration of hydraulic drives is now warranted. A hybrid gasoline-hydraulic automobile with regenerative braking could possibly lead to mileage of well over 70 mpg."

SED reports that it has built a gasoline engine based on the Sanderson mechanism that shows excellent possibilities as a low-friction hybrid engine. Reveals Sanderson, "The vibration can be virtually nil, the low-end torque is extremely flat, the engine idles smoothly at 300 rpm or lower, and the standard emission technology applies equally to these in-line cylinders as it does to conventional crankshaft cylinders. The engine is lighter in weight, smaller than an equivalent crankshaft engine, and its shape fits very well into a low-profile engine compartment."

Scaling the Sanderson mechanism for higher or lower torque or power is another possibility offered by Sanderson. "The mechanism scales linearly, and drawings for a 50 horsepower device have been scaled up to several hundred hp by simply redimensioning the drawings. The forces and loads can be handled without grossly distorting the proportions of the basic mechanism. "SED already has transported the design from fractional horsepower air compressors, to multi-horsepower water pumps, to 500 hp slurry pumps with no serious problems. We feel that this technology may reach the entire range of applications from micro-pumps to thousands of horsepower engines."

The Sanderson is undergoing development and licensing at S-Ram Dynamics LLC, Franklin, Tenn. Click here to visit their website.