Troubleshooting Challenge: Hydrostatic Side Thruster Stops Working

This file type includes high resolution graphics and schematics when applicable.

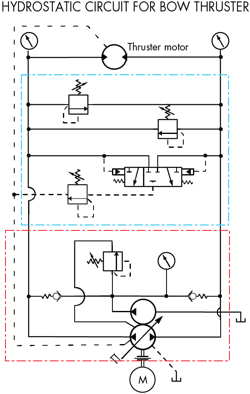

Despite flooding of the Ohio River this past spring, a large party riverboat was able to continue operating using its side thruster to facilitate docking even though high forces from the rushing river occurred. The main propellers provided more than enough thrust to move the boat ahead and astern , and steering to port and starboard was not a problem. The side thruster allowed docking the boat at an angle as the crew navigated the craft sideways, aligning it parallel to the dock.

However, the thruster suddenly stopped working one day, so we were contacted to investigate. The Captain said a diesel engine was driving a gearbox for the side thruster drive, and when they engaged a driveline clutch, the main pump appeared to be rotating. However, they could not get any rotation of the thruster props.

The cruise line’s mechanic told us that the original 0- to 600-psi pressure gauge mounted on the pump was broken, so he replaced it with a 0- to 6,000-psi gauge from one of the main system pressure lines. The charge pressure should be about 250 psi for the main pump, and it would be difficult to read that low a pressure from a 6000-psi gauge.

We looked to see if there was any movement of the gauge needle when the system was energized, but we could not see any at all. The servo control mounted on the pump seemed to function both manually and electronically but the pump would not turn the props in either direction.

Any idea what the problem turned out to be?

Find the Solution

Think you know the answer to this month’s problem?

Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by June 26, 2015, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Jeff Olsen, of A & L Hydraulics, Sioux Falls, S. D., who correctly answered our May 2015 puzzler. A $50 gift card is in the mail to him.

Solution to last month’s problem:

Lumberyard Stacker Cylinder Drops

When the yard stacker lift suddenly dropped, it always happened when the rotation function was selected at the same time. The directional valve sections had load checks in each function. They prevented the backflow of oil from one heavier load to a lighter load function if both were shifted at the same time. We found the load check for the lift function was being held open by what looked like a roll pin. We never found out where the pin came from, but removing the obstruction fixed the problem.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: