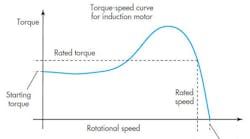

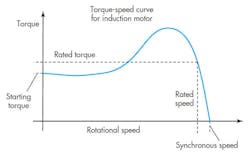

12. Torque-speed characteristics of a typical industrial induction motor show the synchronous speed and rated speed, torque, and the âslipâ between synchronous and rated speed.

The torque-speed curve also shows the difference between the synchronous and rated speed. This speed difference is necessary to keep relative speed between the rotating stator field (synchronous speed) and the actual rotor speed. The speed difference is called the slip of the motor, because it represents slippage between synchronous and actual speed. It’s necessary to create more induced rotor current to boost output torque with increased load.

Now consider what would happen if the rotor catches up to the stator field. There would be no relative speed between the rotor conductors and the rotating field, no induced voltage, and no rotor current/torque developed by the motor. In fact, this can happen only in an ideal motor; that is, a motor with zero friction. Because zero friction is impossible, an induction motor’s rotor can never reach synchronous speed in normal operation.

Popular jargon often states that “the (nominal) motor speed is 1,800 rpm” in a four-pole motor. However, that speed is really the synchronous speed of the stator field. The result is that a four-pole motor with a totally unloaded shaft will accelerate to near synchronous speed, about 1,795 rpm.

When the motor shaft is loaded with some external torque, there’s a decrease in speed, an increase in the relative speed (inducing voltage into the rotor), and an increase in rotor current. The effects of the rotor’s rotating magnetic field changes the phase of the voltage induced back into the stator, elevating the power delivered to the stator and in the end, delivering more power to the shaft load. The rotor’s increased magnetic field “tells the stator” that the shaft load has risen.

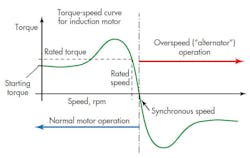

Alternator function in the induction motor

Bilateralism in the induction motor is the phenomenon that allows the electrical power source to “know” that the motor is experiencing a higher load, and that current should be increased to meet the rising output-power need. But bilateralism also means that the machine can operate as either a motor or an alternator to meet changing needs and operating conditions. Can an induction motor function as an alternator, and if so, what are the conditions? Figure 13 answers that question.

If there is a load, sometimes called an “active load,” it overpowers the motor, causing the motor speed to increase above synchronous speed. Under this condition, the motor simply switches to become an alternator and sends the shaft input power to electrical power, which is then sent back onto the electrical grid to be used by other machines on the bus. Such loads, called over-running loads, cause mechanical energy to be sent into what is normally the output.