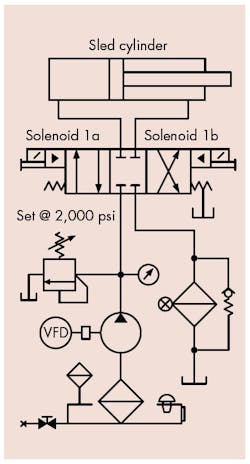

Troubleshooting Challenge: Pump Noise is Intermittent

This file type includes high resolution graphics and schematics when applicable.

The operator of the line complained to maintenance about a strange noise coming from the HPU. Maintenance people found the noise did not occur when the 10-ft.-long cylinder was retracted. However, a loud noise could be heard when cylinder’s piston rod about 7 ft. or more.

The HPU’s oil-level sight gauge was checked, but it showed the level to be comfortably above the low-level mark. Feeling other components wouldn’t cause such a noise, they decided to change the pump—the old “change the pump if you don’t know what’s causing the problem” scenario. Unfortunately, it did not solve the problem. What should they look at next?

Know the Answer?

Submit your solution to Mindy Timmer. All correct solutions received by September 14, 2015, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.