Torsional Vibration Analysis Critical to Tier-4 Engine and Powertrain-System Success

This file type includes high resolution graphics and schematics when applicable.

Unless a gear rattle or other mechanism alerts the operator to high levels of torque fluctuation, torsional vibration problems usually don’t show themselves until the occurrence of driveline-component failure. The most frequent issues have been with the engine crankshaft damper, coupling, clutch, and shaft failure; keyway hammering; spline wear; and premature wear or failure of driven accessories, such as compressors and hydraulic pumps.

Replacing or modifying the failed part generally does not solve the problem. Instead, a systems approach must be used to evaluate the interaction between components.

Torsional Vibration in Internal Combustion Engines

Torsional vibration is a subset of structural dynamics. Simply stated, it is the vibration of a system along some rotational degree of freedom (DOF). The problem has existed ever since fuel was first burned inside a cylinder to create power by pushing a piston down against a connecting rod to the crankshaft. The resulting torque is not smooth because it is only applied when the piston is forced down.

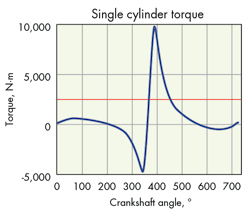

Even then, only a significant torque pulse occurs for the first 40° of rotation after top dead center (TDC) on the power stroke. Torque then suddenly drops to zero. Not only that, but a portion of the torque before TDC is negative because air must be compressed in the engine’s cylinder for the next cycle.

The end result is a peak torque that far exceeds mean torque. This is the root cause of internal-combustion engine torsional vibration issues. Powertrains are dynamic systems and can be represented as masses connected by springs; think of a tuning fork with a resonant frequency (Fig. 1).

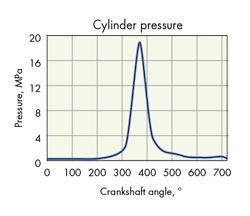

Figure 2 illustrates pressure inside an internal-combustion engine as a function of crankshaft angle. Figure 3 shows the resulting single-cylinder torque pulse as a function of the crankshaft angle.

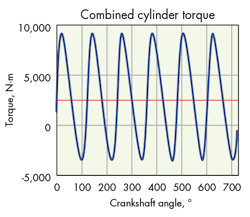

Combining six cylinders into an engine block separates the peak torque of cylinders 120° apart as the crankshaft rotates, but the output torque (Fig. 4) still occurs as pulses. This problem has been the bane of powertrain engineers since engines were first made, and it occurs with Tier-1, -2, -3, and now, Tier-4 engines.

Tier-4 Engine Designs are a Bit Different

Modern engines have been designed to achieve more power with smaller displacement. To gain higher average torque without increasing cylinder size, Tier-4 engines produce higher compression ratios, which produce higher peak torque values. Unfortunately, the higher pressure results in higher-amplitude torque pulsations. Therefore, torque pulsations are even more severe with Tier-4 engines, thus creating more extreme torsional vibration becomes.

This change was necessary, in part, to achieve EPA emission guidelines. Another difference is that Tier-4 engines also feature electronic control systems. Older mechanical systems were not very fast in their response to fuel needs with changing engine speeds. Electronic controls monitor engine load and speed, and fuel rate and timing are continuously variable and can be adjusted very quickly.

Depending on the algorithm, the electronic control unit (ECU) may also generate torsional vibration based on the way it controls the fuel system. For example, the ECU may have a fueling scheme for low speeds (800 to 1200 rpm), and a different scheme for high speeds (1200 to 1800 rpm). Quickly switching between low and high-speed modes could cause the fuel system to initiate additional pulsation or stability issues.

Furthermore, Tier-4 engine designs vary by manufacturer, so the powertrain torsional vibration experience will vary depending on the engine used and the overall powertrain-system design. To ensure acceptable performance of the entire system, engine manufacturers may require an OEM to provide a torsional vibration analysis (TVA) for a particular machine. This will ensure that an otherwise reliable engine will not be put at risk in a poorly designed machine. Sometimes an engine may not be warranted if it is slated for a powertrain with a below-par design.

Benefits of a TVA

When components of a system are torsionally incompatible, engines can be wrecked, crankshaft dampers burned up, drive shafts and couplings broken, and driven equipment—such hydraulic pumps—damaged as torque pulsations excite system resonance. A powertrain with a torsional-resonance problem can make a reliable, well-designed engine seem like a lemon. Independent consultants and specialized agencies perform thousands of TVAs annually to hedge against this risk. This applies not only to new equipment designs, but also older equipment that requires updating to a Tier-4 engine. (One example of how a TVA can impact design can be found at “A Pump that Tolerates Torsional Vibration.”)

These TVA audits generally cost $1,500 to $2,500, which is a small price to pay to ensure reliable, long-term system performance. Repairing or replacing a failed shaft or bearing in a hydraulic pump, for example, can cost several times that amount—and that doesn’t even include the cost of lost production from the machine. Unfortunately, many OEMs and equipment users are unaware of the torsional-vibration characteristics of Tier-4 engines. Likewise, they may not be aware of the benefits and value of doing a TVA after installing the new engine.

We recommend conducting a TVA with a new engine before putting the equipment back into service. We have seen repowered machines operate fine in the field for a year or more, and then they suddenly suffer a drivetrain failure due to torsional vibration. A sound business investment is to perform the TVA at the beginning of the repower design to avoid the expense of field repair and downtime later on.

Torsional vibration could become a problem for any equipment driven by a diesel engine. And, in terms of power, it spans the whole range of applications. It’s not just the big stuff in demanding, severe-duty applications—it’s also the little stuff. Simply put, torsional vibration can, and does, affect everything in the engine powertrain.

Learning from Experience

Simply changing out a failed powertrain component is not the solution to torsional vibration issues. It simply masks the problem until the next weakest link breaks down, and the machine fails again. The solution is a system-wide evaluation that takes into account how torsional vibration affects the entire powertrain.

The “new normal” is that powertrains using Tier-4 engines need close examination. Higher cylinder pressures, increased power from small-displacement engines, and today’s ECUs can all cause higher amplitude of torque pulsation. Design of a durable driveline that performs over the long term has become even more challenging, and is compounded by the trend at some OEMs to extend equipment warranties.

Steve Gluck is Technical Support Engineering Team Leader at Parker Hannifin’s Hydraulic Pump Div., Marysville Ohio. Call (937) 644-3915, or visit www.parker.com/hydraulicpump.

Matthew Witter is Principal Engineer and founder of Structural Dynalysis Ltd., Cincinnati. For more information, call (513) 258-1974, or visit http://strucdynltd.com.

About the Author

Leaders relevant to this article: