Troubleshooting Challenge: Accumulator Pre-Charge Changing

This file type includes high resolution graphics and schematics when applicable.

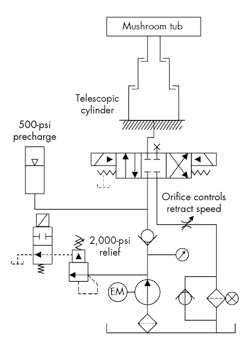

A farmer in Texas grows mushrooms in an abandoned salt mine. It was surprising to learn how many hydraulic systems they use in the processing of their product. They have a simple hydraulic power unit (HPU) with a piston-type accumulator to supplement pump flow. This feeds a three-stage, single-acting telescopic cylinder to raise large tubs of mushrooms up 30 ft. to a conveyor that then transports them up to the surface for processing.

The HPU recharges the accumulator during the retract cycle. Workers send the lift back up again as soon as they reload it. However, a problem arose when the lift began requiring more time to lift the load the required 30 ft. The additional time was robbing production, so something had to be done.

Workers decided the pump was probably wearing out, so they replaced it. When this didn’t fix the problem, they checked to see if the accumulator still held a pre-charge. The pre-charge was about 250 psi higher than what the schematic called for (see the figure), so they reduced it back to the correct pre-charge pressure of 500 psi.

This still did not fix the problem. What would you do next?

FIND THE SOLUTION

Think you know the answer to this month’s problem?

Submit your solution by email to Mindy Timmer at [email protected]. All correct solutions submitted by Nov. 20, 2015, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

SOLUTION TO SEPTEMBER’S PROBLEM

A cylinder with a 5-in. bore and 3½-in. diameter rod takes twice the oil to fully extend compared to what it takes to retract. Maintenance workers asked the same question most people would: Is a low oil level causing aeration noise in the pump? The sight gauge indicated the oil level was comfortably above the low-level mark, so they replaced the pump. When the new pump didn’t solve the problem, they called their local hydraulic service shop for help.

The hydraulic technician instructed a mechanic to remove the filler breather and confirm the oil level. Much to the mechanic’s surprise, the tank was low on oil.

Many sight gauges stain and turn dark when warm oil is present, making it difficult to determine if oil is present or not. If the maintenance people would have cycled the cylinder while observing the oil level in sight gauge, they would have seen that the oil level did not change as the cylinder extended and retracted. No movement on the gauge would have alerted them to the problem.