Milwaukee Cylinderâs Vulcan Series is a collection of options designed to allow a cylinder to operate at higher temperatures or in high ambient temperature environments. Options range from heat-tolerant seals to water-cooled bearings and water cooled-cylinder jackets.

Hydraulic cylinders often operate under conditions that would quickly destroy other methods of linear motion. Dirt, water, wide temperature variations, and shock loading usually pose no serious threat. Intense, heat, however, is often the Achilles heel of any form of power transmission unless special provisions are made.

For example, sometimes an extra-long piston rod or mechanical linkage can be specified to locate the cylinder away from the source of heat. Heat deflectors or thermal insulation may also be used to shield the cylinder from extremely hot ambient conditions. And even though it adds complexity to the system, using a fan to circulate cooling air around a cylinder makes its ambient environment more hospitable.

Even though hydraulic cylinders typically are expected to operate continuously in ambient temperatures that can well exceed 100° F, sometimes solutions such as these still are not practical. So how hot is too hot? Temperatures higher than 180° F are especially harmful to hydraulic fluid and seals.

Taking the Heat

Temperatures this high can quickly degrade hydraulic fluid, reducing its effectiveness as a lubricant. Moreover, excessive heat causes oxidation of the fluid, forming sludge and varnish—contaminants generated by the fluid itself. High temperature also accelerates seal degradation, resulting in loss of resilience and resistance to tearing. These conditions not only lead to leakage, but seal fragments become contaminants within the hydraulic fluid. Of course, premature seal degradation can usually be avoided by specifying a seal material that designed to operate in higher temperatures. For example, ethylene propylene and Viton seals usually accommodate temperatures exceeding 350° F.

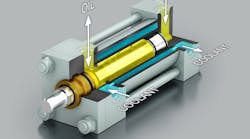

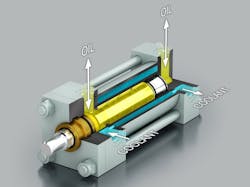

Fortunately, most cylinders don’t have to operate under conditions this extreme. But when they do, Milwaukee Cylinder, Cudahy, Wis., offers its Vulcan Series of standard and custom water-cooled cylinders. The cylinders contain a cooling jacket in which coolant circulates to maintain reasonable temperatures. Cooling the cylinder barrel, though, may not be enough. Therefore, Milwaukee Cylinder also offers cooling jackets for rod bushings, which provide cooling primarily for the rod bearing and rod seal. This solution proves especially useful if the piston rod is exposed to extreme heat while it is extended. When the rod retracts, it becomes a heat source within the cylinder.

Water-cooled cylinders rely on a source of cooling water that absorbs the ambient heat energy and moves this energy away from the cylinder, protecting the cylinder components from exposure to high temperatures. The term, water, though, is a bit of a misnomer. Instead, any of several industrial coolants are used that are not corrosive and that have better heat transfer properties.

The operation of the cylinder should also be considered in these situations. You must account for heat exposure to the rod while the rod is extended. Ideally, the rod should remain in its retracted state, protected by the coolant, and then extend for only short periods of time. A reflective high-temperature boot could also be used in this scenario to help deflect radiant heat from being absorbed in the rod.

Information for this article was provided by Douglas Lucina, Global Marketing & Engineering Leader at Milwaukee Cylinder. For more information, call (414) 769-9700 or visit milwaukeecylinder.com.