PWM: The Unconventional Way to Regulate Pressure

Download this article in PDF format.

Pulse-width modulation (PWM) has been used successfully in electronic control circuits for at least 50 years. It is an efficient method for controlling a large amount of output power while expending a relatively small amount of power in the controller itself. No matter how small, though, the sources of inefficiency in the electronic PWM circuit stem from the finite switching time of solid-state controlling devices and the finite conducting resistance of the switching device when in its on state. The extremely short switching times of electronic devices allow for the efficient use of PWM at frequencies in the kilohertz range, opening up a fairly wide array of suitable applications.

On the other hand, using PWM to perform hydraulic switching requires valves, whose switching times must be measured in tens or even hundreds of milliseconds—not microseconds or nanoseconds as in the case of electronic circuits. The result is that improperly implemented PWM hydraulic circuits produce unwanted vibrations and pulsations at frequencies that can be transmitted to output actuators. This possibility exists with the PWM-regulated hydraulic pressure source.

To investigate this phenomenon, I constructed a PWM-controlled, constant-pressure power supply typical of those used in electrohydraulic servomechanisms and motion-control systems. Representative test results can be displayed and analyzed, and others can use a practical design methodology to apply the PWM method to regulate pressure from a power unit supplying more than a trivial amount of power to a dynamic load. This applied engineering analysis aims to determine the extent a PWM-regulated pressure source can be constructed using a fixed-displacement pump with augmenting accumulator, as compared to the conventional method of using a pressure-compensated pump.

Effects of Non-Constant Pressure

Having constant pressure at the servovalve’s pressure port is critical in motion-control systems using the positional servomechanism that follows a motion profile. Motion-control system performance improves when constant pressure is maintained at the port. Non-constant supply pressures adversely affect the servosystem in three significant ways.

First, if the supply pressure varies when the servomechanism is in a dwell, or fixed position, the variations are propagated to the servoactuator in a way that upsets the force balance. Therefore, the actuator moves, seeking a new point of force balance. This results in a new value for the error signal, and, as its name implies, results in a positioning error. In a machine tool, for example, this can result in machined parts that must be scrapped.

Second, in critical applications—say, a flying cutoff—the flow demanded by the axis undergoing acceleration reduces supply pressure. This forces the servovalve to open more fully than if the supply pressure had not dropped. The pressure reduction further causes an undesired variation in actuator speed. It will either cause an error in cutoff length or demand a time delay for both the supply pressure and the servoaxis to settle, potentially reducing machine productivity.

Third, in multi-axis machines, commanding one axis to move will result in a flow demand and subsequent transient pressure reduction. Other axes that may be at dwell will "feel" the pressure variation at their own respective P-ports. The outcome may be twitching in the otherwise stable axes.

Dealing with Less than Ideal

No pressure source can be made truly constant. The pressure variations can only be reduced to where they result in tolerable positioning and velocity errors. Every application has its own set of application requirements, along with allowable speed variations and positioning errors. Clearly, then, special attention must be paid to the integrity of the pressure supply source in the most critical applications. The only thing separating critical from non-critical applications is the amount of error that can be tolerated.

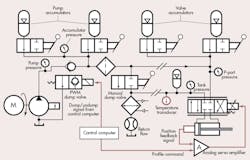

This schematic shows components of an electrohydraulic power unit capable of pressure compensation using a variable-displacement pump, or by keeping pump displacement fixed and using PWM on-off pressure regulation.

If we could build an “ideal” pressure source—which would not vary under any circumstances—we'd have a happy state of affairs. But such a power unit is impracticable and impossible. We can only strive to keep the variations within tolerable limits.

Methods for predicting the expected degree of servomechanism error in the presence of a given supply pressure variation are well documented. So rather than repeat these methods, we will instead concentrate on design features that will achieve a specific pressure variation.

The general process of maintaining a constant pressure in the face of flow variations (disturbances) is referred to as pressure regulation. Countless applications require constant-pressure power supplies, but the aim of this discussion is to evaluate the PWM pressure-control method and devise a design methodology for anyone wishing to implement the concept. Therefore, it is a foregone conclusion that the application requires constant pressure.

A Break from Convention

The conventional method of maintaining a constant pressure in the face of load flow variations uses a variable-displacement, pressure-compensated pump with an isolating check valve and an augmenting accumulator. The accumulator accommodates the sudden flow demands of the load flow and is critical to the dynamic regulation of supply pressure.

Standardized dynamic and steady-state methods exist for testing pressure-compensated pumps. The pressure-compensated pump is not the object of this investigation. Rather, it is to provide a comparison to a familiar pressure-control method. It is the standard by which at least some judgment will be made regarding the effectiveness of the PWM pressure-regulation method.

Establishing Ground Rules

The power unit used as the subject of this report is drawn in hydraulic schematic form (see figure). It consists of an engine-driven, variable-displacement pump with appropriate valving and accumulators to maintain relatively constant pressure under varying flow demands. The load consists of a time-varying, but programmable, load flow. The power unit can function using either conventional pressure compensation or with PWM (on-off) pressure regulation while keeping pump displacement fixed.