If the mountain won’t come to Muhammed, then Muhammed must go to the mountain. That’s the principle behind mobile material crushers. Large, stationary crushers can crank out impressive piles of crushed rock or concrete in no time. But some projects—such as road construction and utility projects—can go faster by bringing the crusher to the work area, rather than having to transport material to a centrally located crusher. With output capacities ranging to hundreds of tons per hour, these powerful brutes can hold their own against larger, stationary machines by smoothly and efficiently reducing construction and demolition debris into pre-selected sizes for gravel, fill, or subsequent processing.

Rocks and concrete chunks in sizes up to 3 ft by 3 ft and more than a foot thick can be fed into these crushers and reduced to pieces as small as 1 in.3 Output material can then be used for roadbeds, pipe beds, fill, or aggregate production—or simply graded into the soil for disposal.

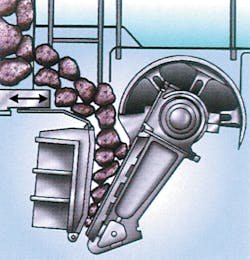

After input material is dumped into a hopper, it travels through a grizzly feeder, crusher jaws, and to a conveyor, which carries crushed material out of machine.

Getting Down to Business

After the mobile crusher is transported to the job site on a trailer, an operator maneuvers it into convenient positions under its own power—ready to work in spaces too tight for larger, more cumbersome crushers or inaccessible to crushers that must be towed or pushed into final position. Mobile crushers significantly increase productivity because the unit can move around a site to crush material wherever it is stockpiled, versus hauling material to a stationary crusher from several locations.

The crushing process begins when material is loaded into the machine’s vibrating grizzly feeder. The feeder is mounted on springs and vibrated by an eccentric drive located underneath the feeder pan, which protects it from misfed material that may fall out of the feed hopper. The vibration causes pieces of material to impact each other to reduce their size and applies force that is angled to the feeder, directing material toward the feeder’s discharge end. This action also segregates the material, causing finer particles to fall downward.

As the material travels through the grizzly feeder, finer material settles to the bottom, falls through openings onto a conveyor and transported past the crushing chamber. Separating out the smaller pieces extends the life of the crushing chamber and boosts machine output by reducing the amount of material that passes through it. The bypassed material rejoins the main material flow exiting the discharge of the crushing chamber or is segregated as a separate and discarded.

Hydraulic Design

A big advantage to an all-hydraulic design (besides the convenience of mobility) is that a low-speed, high-torque (LSHT) hydraulic motor driving the machine’s crushing jaws generates its maximum torque as soon as it starts. If debris gets wedged in the jaws of a mechanical machine, it usually must be stopped to clear the obstruction, then re-started. In contrast, the hydraulic motor can be instantly reversed to clear some jams then resume crushing without having to clear out a full load.

A powerful low-speed, high-torque motor drives an eccentric weight (upper right) to cycle a sliding jaw that crushes concrete, stone, and other materials into pieces about the size of ice cubes.

A pair of variable-displacement, axial-piston pumps supplies the propulsion and crusher drives—but not simultaneously, because the machine does not travel and crush at the same time. The pumps are rated at 5,000 psi, as is the LSHT variable-displacement, axial-piston motor that powers the crusher.

The motors power left and right track drives for moving the crusher around a job site. Once the machine reaches its destination, the operator shifts diverter valves to route hydraulic flow for crusher operations. This flow powers a hydraulics motor that rotates an eccentric weight to cycle a movable jaw toward and away from a stationary jaw in short, powerful spurts. The stationary jaw is positioned perpendicularly; the movable jaw forms an approximate 45-deg. angle with it. Debris tends to move toward the apex of the angle, where the maximum crushing forces are developed.

A feeder plate feeder, powered by another variable-displacement hydraulic motor, moves incoming debris into the jaws with a short, oscillating motion. The feeder strokes rapidly toward the jaws, then stops suddenly. Debris riding on the feeder slides off into the crusher, and the plate strokes slowly in reverse to pick up its next load. The speed-adjustable feeder shares flow with the motor for a discharge conveyor.

At the operator’s station, electrical controls actuate valves that control each of the crusher’s functions. A single button will stop the crusher motor, feeder belt, and conveyor if necessary, while other functions have their own operator interfaces to facilitate efficient startup. An automatic control shuts down the crusher in the event of a malfunction to prevent accumulation of crushed materials. Low engine noise, sound-suppression materials, and the relatively quiet LSHT motor increase the level of operator comfort.

Serious Hydraulics for Tractors

When hydraulic systems were first incorporated into general-purpose tractors, they must’ve been not much more than an afterthought. They provided pressurized hydraulic fluid to run a variety of useful attachments, but they left a lot to be desired with respect to power, control and, especially, efficiency. Fortunately, today’s tractors offer much greater hydraulic power, controllability, and load sensing, along with other features to improve efficiency.

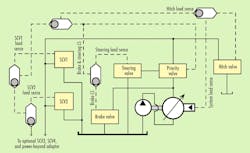

Using a system of shuttle valves, the closed-center hydraulic system of a general-purpose tractor can deliver the highest load pressure signal to the load-sensing control of a pressure- and flow-compensated axial-piston pump. The load-sensing control of this tractor’s main pump maintains pressure more than 400 psi above load pressure until the pump goes off stroke at nearly 3,000 psi.

In the Beginning

The tractor’s hydraulic system uses a gerotor-type charge pump, driven by a live power shaft, to supply fluid through a spin-on filter to a secondary elevated reservoir. This reservoir ensures that the main pump is not starved for fluid even when the tractor first starts. Any excess charge-pump fluid can be diverted to the tractor’s lubrication system.

A spin-on hydraulic filter has a ß10 rating of 5. A bypass valve opens when the filter element becomes restricted (indicating it has reached its dirt-holding capacity), and a light in the tractor cab alerts the driver when this occurs. The bypass valve also opens during cold-weather startup to help the hydraulic system warm up more rapidly.

All high-pressure hydraulic functions on the tractor are plumbed in parallel, using metric flat-faced O-ring fittings. These high-pressure functions include power brakes, the three-point hitch, power steering, and as many as four selective control valves (SCVs) that deliver pressurized fluid to hose couplers for implement operation. A power-beyond adapter is another option. The brake valves receive pressurized fluid directly from the main pump. In the event of a hydraulic power loss, the dual-stage brake plunger provides manual braking. A large plunger moves the brake piston against the disc. A smaller plunger can then build high pressure with minimal pedal effort.

All other pressurized fluid is delivered to a priority valve. The priority valve ensures that the power steering and brake valves receive enough fluid before diverting fluid to the electrohydraulic hitch control valve and the SCVs. The priority valve also regulates steering pressure to 175 psi above the steering load-sensing pressure. The double-acting cylinder steering system provides balanced steering flow and plenty of steering torque. Even with maximum load in the bucket and the tractor standing still, the steering system still has enough capacity to turn the front wheels.

Two hitch cylinders are controlled by a solenoid-actuated, hydraulically piloted directional-control valve. The 3-position, 6-way directional valve and cylinders are sized to deliver up to 10,000 lb of lifting force. Electronic sensors monitor hitch position and draft load, and this information is processed by the hitch control unit to regulate the hitch valve. A command lever can raise or lower the hitch, or it can be left in any position to maintain a given height. An up/down rocker switch lifts or lowers the hitch, and the command lever determines how far the hitch can be lowered.

A remote switch on the tractor fender permits hitch operation from outside the cab. A rate-of-drop switch controls the drop speed of the hitch; and the raise-height switch limits the extension of the hitch cylinder. The load/depth mix switch blends more or less draft sensing. When the directional valve is in its detented position, draft sensing is locked out to give the operator more precise position control.

Selective Control Valves

This simplified schematic of a closed-center hydraulic system indicates a cascaded shuttle-valve load-sensing system and a parallel nature of system architecture.

Manual 4-position, 10-way SCVs deliver pressurized fluid to implements connected to the quick-acting couplings mounted at the rear of the tractor. These SCVs have load-lift check valves in their extend and retract ports to provide low drift-down rates of implements. The SCV manual control levers are spring-loaded to neutral and have three detented positions: Hydraulic detents keep the valve in its extend or retract positions, and a mechanical detent holds the valve in float. As hydraulic detent options, the operator can select:

- No detent—This eliminates operation of the hydraulic detent mechanisms. The lever always is spring-loaded to neutral so the operator can control and feather implement movement, which is useful for loader operations, for example

- Continuous detent—Using this option, the valve lever remains in the detent even though a cylinder fully retracts. This option is ideal for running hydraulic motors.

- Automatic kickout—Using this option, the valve lever returns to neutral when a cylinder stalls or peak pressure is sensed.

Hydraulic detents on extend and retract are handy because, upon tractor shutdown, the SCV lever will spring-return to neutral for no-load restarting.