Managing Friction to Optimize Hydraulic Cylinder Performance

Industries, including fluid power, are shifting focus to improve equipment efficiencies, making it more sustainable. Achieving sustainability typically involves reducing the amount of power needed to operate such equipment, resulting in less consumption of natural resources. Industries may evaluate materials used to construct the equipment for their environmental impact during production and use and the ability to recycle when the equipment reaches the end of life. By analyzing each sub-system and applying sustainability goals, the operator may achieve the intent of attaining overall sustainability.

Friction is the force of resistance as one part moves on, or relative to, another part. There are many instances in fluid power components, such as those fitted to a backhoe loader, where friction occurs. These resistance forces must be overcome to generate work and movement, resulting in a demand on the power unit and the energy resources driving it. By reducing friction in the components that interact with the machinery, energy consumed is reduced, improving the overall sustainability of the equipment. This approach has companies considering new types of lubrication, materials or product geometry that offer less frictional drag, additionally ensuring these new solutions are not harmful to the environment.

READ MORE: Hydraulic Seals Designed for Heavy Duty

Hallite is supporting these challenges by focusing on reducing friction in the hydraulic cylinder sealing systems while ensuring the best seal performance. For example, in a backhoe loader, hydraulic cylinders are vital to allow the unit's proper operation. Depending on the complexity of the unit, upwards of 10 cylinders in varying sizes may be needed for standard operation.

Rod Seals

Rod seals are required to provide exceptionally good leak protection and consequently induce a relatively high friction force on the dynamic rod. The rod seal performance is impacted by many factors, such as pressure, quality of lubrication, surface finish, material, and geometry.

To better understand this impact, Hallite teamed up with the Milwaukee School of Engineering (MSOE) to create a test method to quantify the frictional force induced by a rod seal (see photo below). These seals are dynamic and increase loading as pressure increases in the system to prevent leakage.

Understanding Rod Seal Friction

The test fixture assessed both break away, or force needed to start rod movement, and the run force, or force required to keep the rod in motion. In addition, friction was measured at three different pressure points to understand the change in friction due to the seal responding to a higher pressure.

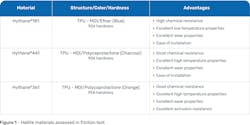

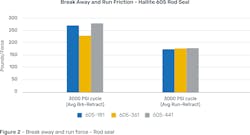

Hallite evaluated the Type 605 asymmetrical twin-lipped u-cup in several different Hythane TPU materials to establish a baseline (Figures 1 and 2).

Figure 2 shows the break away and dynamic friction forces induced by a 605 rod seal. When considering this seal in Hythane 181, the force required to overcome friction was 276 lbf at 3,000 psi applied pressure, and then reduced to 193 lbf to overcome dynamic friction and maintain a stroke.

In considering a typical hydraulic cylinder with a 3-in. bore and 1.5-in. rod, in a typical hydraulic system of pumps and valves, the dynamic friction forces would consume approximately 0.3 hp. Further assumptions in how many cylinders are in use, to do the work required, result in a demand of around 1.5 hp, which equates to more than 2% of the power generated in a typical medium-duty backhoe loader.

Reducing Friction in Rod Seals

With the baseline understanding of the Hallite 605 rod seal profile and materials, Hallite is now working to develop new profiles and materials to reduce friction alongside ensuring the best sealing properties. Further development work is underway using test methods to assess friction durability to understand the impact on longer term sealing properties. This has allowed for the development of new seal profiles and materials showing promising results.

Work is also underway with different hydraulic fluids to understand better how friction on the seal might be improved based on the viscosity and fluid type. Although much progress has been made, Hallite strives to offer improved solutions. These consist of not only seal and materials designs but also recommendations on the best combinations of fluids and operating conditions to achieve the best performance with a high level of sustainability for hydraulic fluid power sealing products.

This article was written and contributed by Andrew Iddeson, Global Technical Director, Hallite Seals International, and Chuck White, Director of Sales and Marketing, Hallite Seals Americas.

About the Author

Andrew Iddeson

Global Technical Director, Hallite Seals International

Chuck White

Director of Sales and Marketing, Hallite Seals Americas

Leaders relevant to this article: