Case Study: Proper Seal Choice and Press Programming Mitigate Yield Issues and Scrap Waste

Proper sealing of cross drilled holes in the outer shell of automatic transmission cases is necessary to prevent fluid loss. Cross drilling of the casing is often required during the manufacturing process to create and precisely connect the many channels and passages common to the transmission’s valve body which enable control functions to be performed.

When a transmission manufacturer found its previous sealing method would not work for its new thin-walled case design, it turned to The Lee Company to provide an alternative solution.

The Challenge

The manufacturer is a long-time customer of Promess, a provider of monitoring and motion systems for various assembly and test applications. When manufacturing transmission cases, it had typically used Promess’ Electro-Mechanical Assembly Press (EMAP) to press a steel ball bearing and seal the cross-drilled hole to prevent any fluid losses.

READ MORE: Going Beyond PID in Hydraulic Motion Control

However, the manufacturer found this method did not work well for its thin-walled transmission case. It caused the housing to crack as well as unacceptable leakage rates and warranty issues.

The EMAP is designed to monitor and precisely control peak force and final position. But an evaluation of its use for the thin-walled case established only distance was controlled because the ball pressing application was programmed by a user to stop at a specific distance. Therefore, the tight tolerances normally used for the dimensions of the ball bearing and the diameter and surface finish of the cross-drilled hole were not followed, leading to cracks and leakage issues.

New Sealing Method Offers Potential Solution

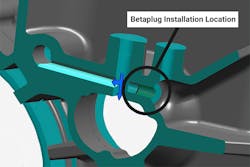

To overcome these issues, the manufacturer chose to use a Betaplug expansion plug from The Lee Company in place of the steel ball bearing. The company describes its Betaplug as a pre-assembled, two-piece tapered expansion plug. It features an inner pin and an outer plug body with lands and grooves which bite into the transmission housing during installation to create a leak-tight seal.

When installed in a matching tapered bore, the Betaplug provides proper sealing. According to The Lee Company, the plug reduces unnecessary expansion and has a predictable boss stress suitable for brittle materials or thin-wall conditions like those of the transmission manufacturer. This is due to the size of the tapered pin on the Betaplug precisely controlling its expansion and making the resulting boss stress predictable, easing installation as well as making it repeatable.

The Betaplug works without threads or sealants, and features a single-piece design which helps to reduce costs for manufacturers. Its tapered design removes the need to use tight tolerances during the manufacturing process, helping to ensure proper sealing in even high-volume production applications.

Once the transmission manufacturer began using the Betaplug expansion plug, cracks in the housing and production yield issues were eliminated.

However, it was discovered an improper installation specification was carried over to production of the thin-walled transmission which lead to new issues:

- an unacceptable scrap rate

- yield issues

- damages in the fixturing.

The manufacturer contacted Promess and The Lee Company to have both companies examine the installation and assembly process to help find a solution to these new manufacturing issues.

Proper Programming and Installation are Key

Upon examination of process used by the transmission manufacturer, The Lee Company and Promess determined adjustments were necessary to both installation of the Betaplug and programming of the EMAP.

Engineers from The Lee Company determined that when installing the Betaplug, it was being over-pressed. This led to the creation of excessive radial force when the pin moved to expand the plug’s body and extruded the plug in the installation bore.

The manufacturer also wanted to install the plug at a fixed point in the bore because it knew this is where the steel ball bearing best performed. However, this was not a suitable option for the Betaplug because it caused excessive installation force to be created.

Despite these findings, the manufacturer wanted to continue with its processes because the plugs were not failing in the field and the company decided it could accept the scrap rate.

Promess engineers evaluating the process recommended changing the programming for the press. Instead of measuring force level or distance, they suggested combining EMAP instrumentation with data processing provided by Promess’ Motion Controller. Doing so would enable the measurement and control of absolute force and distance as well as more complex aspects such as the rate-of-change between those measurements.

With these more detailed measurements, the press can be stopped once the pin is correctly inserted into the plug to prevent excessive force and over-insertion from occurring. In addition, the technology is capable of detecting if parts are upside down, sideways or missing a pin/component.

To ensure this new programming would work for the transmission manufacturer, engineers at Promess and The Lee Company conducted extensive lab testing. This testing was done prior to making any changes at the manufacturer’s facility.

The combination of updating the EMAP programming and correcting the Betaplug’s installation resolved the yield issues and reduced the manufacturer’s scrap rate. Since these changes were made the manufacturer has also not received any warranty returns for leakage issues.

This article is based on information provided by The Lee Company and originally published on its website.