Understanding Electrohydraulic Valve Types

Electrohydraulic valves are often classified as either servo or proportional, a distinction that gives an indication of expected performance. However, this classification tends to generalize and blur the true differences between the various types of electrohydraulic valves available in the market.

Understanding the different types of electrohydraulic valves available and how each can help to control pressure or flow ensures the right valve is selected for a given application.

Traditionally, the term servo valve describes valves that use closed-loop control. They monitor and feed back the main-stage spool position to a pilot stage or driver either mechanically or electronically. Proportional valves, on the other hand, move the main-stage spool in direct proportion to a command signal, but they usually do not have any means of automatic error correction (feedback) within the valve.

Confusion often arises when a valve's construction resembles a proportional valve, but the presence of a spool position feedback sensor (usually an LVDT [linear variable differential transformer]) boosts its performance to that rivalling a servo valve. This reinforces the concept that designers and suppliers should use common terminology and focus on the performance requirements of the particular application at hand.

Typically, proportional valves use one or two proportional solenoids to move the spool by driving it against a set of balanced springs. The resultant spool displacement is proportional to the current driving the solenoids. The springs also center the main stage spool. Repeatability of the main-stage spool position is a function of the springs' symmetry and ability of the design to minimize nonlinear effects of spring hysteresis, friction, and machining tolerance variations.

An Explainer on Servo Valves

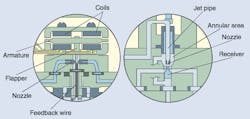

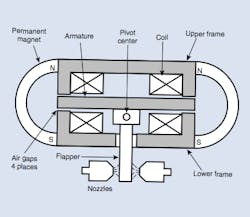

The term servo valve traditionally leads engineers to think of mechanical feedback valves, where a spring element (feedback wire) connects a torque motor to the main-stage spool. Spool displacement causes the wire to impart a torque onto the pilot-stage motor. The spool will hold position when torque from the feedback wire's deflection equals the torque from an electromagnetic field induced by the current through the motor coil. These two-stage valves contain a pilot stage or torque motor, and a main or second stage. Sometimes the main stage is referred to as the power stage. These valves can be separated primarily into two types, nozzle flapper and jet pipe, as seen in Figure 1 below.

The electromagnetic circuit of a nozzle flapper or jet pipe torque motor is essentially the same. The differences between the two lie in the hydraulic bridge design. A hydraulic bridge controls the pilot flow which, in turn, controls the main-stage spool movement. In a nozzle flapper, the torque produced on the armature by the magnetic field moves the flapper toward either nozzle depending on command-signal polarity. Flapper displacement induces a pressure imbalance on the spool ends which moves the spool. In a jet pipe, the armature movement deflects the jet pipe and asymmetrically imparts fluid between the spool ends through the jet receiver. This pressure imbalance remains until the feedback wire returns the jet pipe or flapper to neutral.

Historically, jet pipe and nozzle flapper servo valves have competed for similar applications that require high dynamics. Typically, better first-stage dynamics gives the nozzle flapper better overall response, whereas improved pressure recovery of the jet/receiver bridge design gives the jet pipe motors higher spool driving forces (chip-shearing capability).

Both valves require low command currents and therefore offer a large mechanical advantage. Motor current for these style valves is typically less than 50.0 mA. Note that these servo valves are also proportional valves, because spool displacement and flow are directly proportional to the input command.

READ MORE: Getting the Most out of Electrohydraulic Valves

Direct-Driven Electrohydraulic Valves

Direct-driven valves, unlike hydraulically piloted two-stage valves, displace the spool by physically linking it to the motor armature. These valves usually come in two basic varieties, those driven by linear force motors (LFM) and those actuated by proportional solenoids. Within these two general classifications, the valves can be separated into proportional and servoproportional. The distinction is based on the use of a position transducer to provide spool position feedback. Servoproportional valves must incorporate closed-loop spool position feedback to increase repeatability and accuracy necessary for high-control applications. Typically, servoproportional, direct-driven valves have an overall lower dynamic response than hydraulically piloted two-stage valves with the same flow characteristics. This is usually due to the large armature mass of the LFM or solenoid and the large time constant associated with the coil, which is a function of the induction and resistance of the coil.

Unlike hydraulically piloted servos, direct-driven valve performance does not vary with changes in supply pressure. This makes them ideal for applications where pilot flow for first-stage operation is not available. Direct-driven valves also tend to be viscosity insensitive devices, whereas nozzle flapper and jet pipe valves work best with oil viscosity below 6,000 SUS. However, most direct-driven valves cannot generate the high spool driving forces of their hydraulically piloted counterparts.

Like the torque motor used in the nozzle flapper/jet pipe servos, the LFM allows for bidirectional movement by adding permanent magnets to the design and therefore making the armature motion sensitive to command polarity. In the outstroke, the LFM must overcome spring force plus external flow and friction forces. During the backstroke to center position, however, the spring provides additional spool-driving force which makes the valve less contamination sensitive. Magnetic-field forces are balanced by a bidirectional spring that lets the spool remain centered without expending any power.

Unlike the LFM, the proportional solenoid is a unidirectional device. Two solenoids oppose each other to achieve a centered, no power, fail-safe position. When a single solenoid is used, holding the spool at midstroke requires a continuous current to balance the load generated by the return spring. This makes the design less energy efficient than its LFM or a dual-solenoids counterpart. During a power loss, the LFM and dual proportional solenoid designs fail to a neutral position and block flow to the load, that is the piston. When a single solenoid design loses power, the spool must move through an open position that tends to cause uncontrolled load movements.

Creation of Multistage Valves

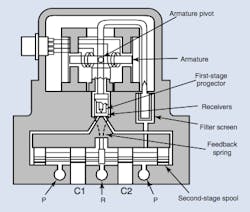

All of the aforementioned designs can be used to create a multistage hydraulic valve. The approach for each design is specific to the application requirements. Usually, most designs do not exceed three stages. Mounting a nozzle flapper, jet pipe, or direct-driven valve onto a larger main stage satisfies most requirements for dynamics and flow.

Sometimes, the jet pipe valve is used in a multistage configuration where the mechanical feedback of a traditional jet pipe is replaced with electronic feedback. This servojet style has pilot characteristics of a typical jet pipe. Depending on the required control, many multistage valves can close a position loop about the main stage using a linear variable differential transducer. This device monitors the spool position. In case of hydraulic power loss, springs on opposite sides of the main stage spool return it to a neutral position.

A Closer Look at Servo Valve Designs

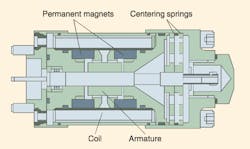

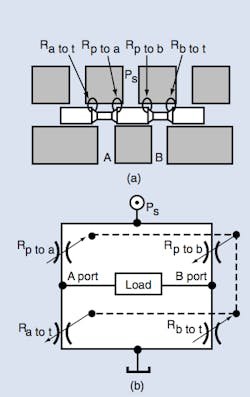

Viewing the principal internal parts of a flapper-nozzle servo valve, as shown in Figure 3 below, it should be clear that torque applied from a torque motor to the flapper arm, say in the clockwise direction, moves the flapper closer to nozzle A and tends to close it.

Concurrently, the flapper moves away from nozzle B to allow more flow through it, so the net result is a rise in pressure Pa and a drop in pressure Pb. The pressure difference, Pa - Pb is felt across the two ends of the main valve spool, driving it to the right and creating communication from port P to port B, and from port A to port T.

A 4-way directional control valve is represented in Figure 4. When the valve spool moves to the right, Rp to a and Rb to t open while Rp to b and Ra to t close. Fluid flows from the valve's A port to the load and returns via B port to tank. Left spool movement opens Rp to b and Ra to t so that fluid flows from the valve's B port to the load, returning to tank via A port.

Pilot-Operated Valve Options

Valves with larger flow capacities need pilot stages to boost the power necessary to shift the larger spools. The electromechanical methods used for this staging are torque motors, force motors, and proportional solenoids.

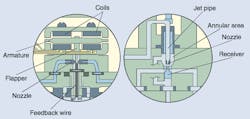

Torque motors, shown in Figure 5 below, are electromechanical rotary machines whose rotational travel is restricted — often to less than one or two revolutions — and are nearly always used for a piloting function. They are fitted with permanent magnets as the major flux source with the flux paths arranged to form a force bridge. Their limited rotation allows the armature to be mounted on a stiff flexure spring rather than bearings, although there is one known proprietary exception that uses a soft spring. The stiff spring and lack of bearings virtually eliminate hysteresis caused by bearing restriction.

Incoming current creates a second set of magnetic fluxes that unbalance the force bridge and results in net torque. The torque causes angular rotation until the flux-induced torque equals the counter-torque of the flexing spring plus any external load. An important characteristic of the torque motor is that the direction of rotation is affected by the direction of current through the coil. The electromagnetic field caused by the current is compared to the field of the permanent magnet in the magnetic bridge circuit and rotation ensues in a commensurate direction.

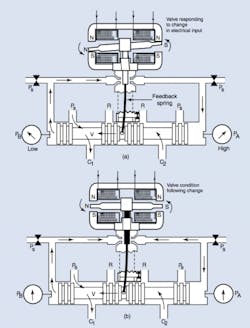

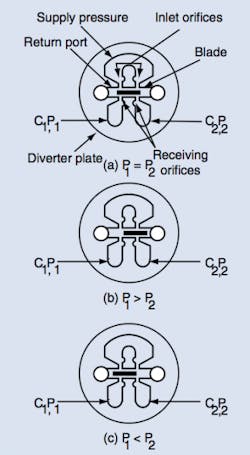

In the final valve assembly, the torque-motor armature is connected to a flapper sitting between two opposed nozzles, a jet pipe, or a swinging wand or blade. These last two steer a fluid stream, shown below in Figure 6, branch B. Basic operating principles and conceptual construction of flapper-nozzle and jet pipe servo valves are indicated in Figures 7 and 8 below, respectively. Torque motors almost exclusively pilot servo valves, and usually require less than 1W of power to fully operate although that is not a hard-and-fast rule.

Torque from the torque motor of a jet pipe servo valve steers the jet to one receiver or the other, unbalancing spool end pressures. Movement of the main spool continues until the feedback spring between the main spool and jet forces the jet pipe back to near null. Main spool position then is commensurate with coil current.

The flapper nozzle has two different implementations: the one already mentioned is the stiff design, wherein the force due to the impinging nozzle flow is small in comparison to spring and torque motor forces. In soft designs, the torque motor and nozzles are deliberately sized so that nozzle effluent causes a significant force on the flapper. One argument concludes that this design is more tolerant of certain contamination problems. The argument goes like this: when the two fixed orifices are open fully and unclogged, the unpowered flapper will center due to a combination of fluid-momentum force acting on the flapper, restoring force on the light spring, and magnetic force in the torque motor.

Should one of the nozzles or fixed orifices become partially blocked, reduced effluent flow produces less force on the blocked side of the flapper. The flapper then moves toward the clogged bridge leg until reduced force from the opposite receding nozzle equals the diminished flow force from the partially blocked nozzle. Current input to the torque motor then causes the flapper to move about a shifted neutral, but the pressure does not go to a hard-over level. The main spool might not shift fully in one direction, however.

The swinging wand, as seen in Figure 6 above path D, has a mechanical-to-hydraulic interface that is proprietary. The versions of this interface include:

- dual nozzle where the two fluid streams are deflected off the outside edges of the wand, and

- single nozzle, where a single fluid stream passes through a central hole in the wand.

Consider the dual-nozzle version, shown below in Figure 9. The two fluid streams issuing from the source side of the pilot head are collected in opposing receiving ports. When a current into the torque motor causes the wand to swing, one receiving port experiences a rise in pressure while the other experiences a pressure reduction. As in the case of the jet pipe and flapper nozzle pilots, the resulting difference in pressure shifts the valve's main spool.

The single-nozzle version has a hole laterally bored and centrally located in the wand such that the single fluid stream issuing from the single nozzle must pass through the hole. When the wand is centered, equal pressures are collected in the two receiving ports. A current into the coil causes the wand to shift and the fluid stream is deflected off the inside edge of the central hole resulting in different pressures being collected in the two receivers. The resulting differential pressure between the two receiving ports shifts the main spool.

This swinging-wand design has a supply pressure limitation in that the pilot head must be sized for a particular supply-pressure range. If flow issuing from the nozzle(s) is excessive, fluid momentum force acting on the wand can pin it against the receiver side, locking it there. Installing an orifice — matched with the supply pressure and the needs of the pilot stage — in series with the nozzle side, remedies this problem. An approximately 2:1 change in supply pressure is possible with a single orifice.

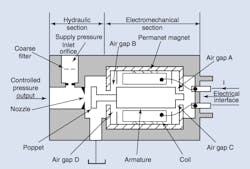

Force motors are the linear equivalent of torque motors in that they also have permanent magnets inside. Therefore, the direction of motion depends upon the direction of input current, as shown in Figure 12 below. There is only one manufacturer of force motors in the U. S.: Fema Corp., Portage, MI. The two permanent magnets each create attractive forces, each urging the armature toward it, but nominally offsetting one another when centered. Additionally, a stiff centering spring prevents either of the natural regenerative attractive forces from pulling the armature either way.

When a current is applied in the direction shown in Figure 12, the resulting electromagnetic fields act to strengthen the magnetic fields by increased flux density in air-gaps B and D while at the same time weakening the fields in air-gaps A and C. The resulting force moves the armature and poppet to the left. State-of-the-art force-motor design produces a maximum of about 5 lbs. of stall force, about 0.02-in. of travel (no load) at about 5W of power.

Reviewing Proportional Solenoid Valves

Proportional solenoids are about 30 years old and are manufactured by a number of companies worldwide. Some market their solenoids to U. S. industry, while others supply themselves. All competing products have similar performance specifications. State-of-the-art proportional solenoid designs yield these approximate typical specifications:

- maximum force of 20 lb.

- proportioning travel of 0.10 in. current, 12V coil, 1.5-2.5 A, and

- power of 15-25W.

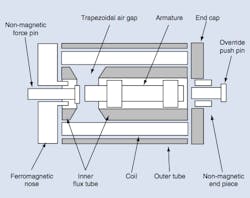

Figure 11 below indicates approximate construction detail of a proportional solenoid. The secrets to success lie in forming the proper trapezoidal air gap dimensions and in keeping stiction low.

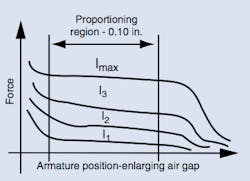

Figure 12 below shows a representative force-displacement curve for a proportional solenoid. Its unique characteristics are a region of relatively constant force as the armature changes position, plus relatively linear changes in force for changes in solenoid current, both performance goals sought by the solenoid's designers. It is probably true that neither the constancy of force nor the linearity with current are as important as the manufacturers would claim. Things incorporated external to the solenoid substantially affect performance of the total valve: use of pressure feedback or armature-position feedback, for example. Furthermore, the enormous versatility of the hardware and software of modern computers makes control and linearization a fairly straightforward task.

Comparing Solenoid and Motor Devices

Some differences between proportional solenoids and force/torque motors are apparent in the specifications while others are not. Torque/force motors require lower current levels. Proportional solenoids:

- require much higher electrical input power than their motor counterparts,

- produce substantially greater mechanical travel than motors,

- produce higher levels of force,

- produce higher levels of stiction,

- operate with greater hysteresis, and

- generate force in a direction independent of current direction.

Therefore, to make a 4-way directional valve operate requires two proportional solenoids but only one force/torque motor.

All of these factors make proportional-solenoid drive electronics more complex than that necessary for force/torque motors. Proportional-solenoid power requirements have caused manufacturers of proportional-valve drive electronics to adopt pulse width modulation (PWM) as the power-output method of choice. The major reason for the use of PWM is to handle the high-output power required of the solenoid without overburdening the power-output transistors.

There is a second benefit of using PWM: if the PWM frequency is sufficiently low, it automatically provides a mechanical dither that helps minimize stiction-induced hysteresis. In some valves the effects of dither can only be described as dramatic when looking at the reduction in hysteresis. The correct dither frequency must be determined after the valve is designed. Furthermore, the frequency selected must be a compromise between propagating the dither pulsations imperceptibly into the hydraulic circuit and yet achieving sufficient reduction in stiction. A low frequency helps the stiction problem but if too low, the user of the hydraulic system can feel the pulsations.

U.S. industry uses PWM frequencies from about 33 to about 400 Hz. At least one European manufacturer uses 40 kHz and receives no dither effects whatsoever. Their amplifier supplies dither with a separate on-board dither generator. There is an advantage to this method: dither power remains constant throughout the modulation range, whereas when relying on the PWM frequency for dithering, the dither power varies with the amount of modulation. There is none at the 0 and 100% modulation points, but maximum at 50% modulation.

READ MORE: Solenoid Valve Quality in Arctic Can Impact Oil and Gas Applications

A Summary of Pilot-Operated Valves

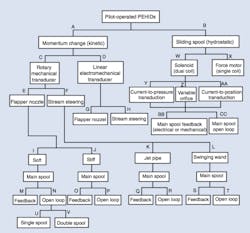

Figure 13 below shows a family tree of all electrically modulated, continuously variable pilot-operated valves. It is a peculiarity of the U.S. hydraulic valve manufacturing industry that each terminus of the tree also tends to define a specific manufacturer's product. For example, the A/C/E/I/N/V path rather accurately describes the servo valve built by Danfoss' Controls Div. in Minneapolis (note that its mate, U, has no supplier).

In contrast, though, the A/C/E/J/O path is well populated. That is where the products of Moog, Bosch Rexroth, Parker Hannifin's Dynamic Valve and others have congregated.

How to Choose the Right Electrohydraulic Valve

To choose the proper electrohydraulic valve for a specific application, designers must consider specific application and system configurations. Supply pressure, fluid type, system force requirements, valve dynamic response, and load resonant frequency are examples of the various factors affecting system operation.

Hydraulically piloted valves are sensitive to supply pressure disturbances, whereas direct-driven valves are unaffected by supply pressure variation. Fluid type is important when considering seal compatibility and viscosity effects on performance over the system's operating temperature range.

Total force requirements must include all static and dynamic forces acting on the system. Load forces can aid or resist, depending on load orientation and direction. Forces required to overcome inertia can be large in high-speed applications and are critical to valve sizing.

The load resonance frequency is a function of the overall travel stiffness, which is the combination of the hydraulic and structural stiffness. For optimum dynamic performance, a valve's 90° phase point should exceed the load resonant frequency by a factor of three or more.

The valve's dynamic response is defined as the frequency where phase lag between input current and output flow is 90°. This 90° phase lag point varies with input signal amplitude, supply pressure, and fluid temperature so comparisons must use consistent conditions.