Troubleshooting Challenge: Hydraulic System Overheats in Aluminum Recycling Plant

This file type includes high-resolution graphics and schematics when applicable.

An aluminum recycling and smelting plant has a hydraulic feeder unit that pushes scrap aluminum into a smelting furnace. Once melted, the aluminum flows to other equipment that separates impurities and directs the relatively pure aluminum into large molds, where it solidifies as ingots. After the ingots have cooled, they are ready to be shipped to customers.

The feeder uses a hydraulic cylinder at the bottom of a feed chute to shear the incoming scrap aluminum and push it into the furnace. The cylinder operates at a rate determined by a motion controller, which receives several feedback signals from the machine (such as how fast the aluminum melts, the scrap feed rate, and weights).

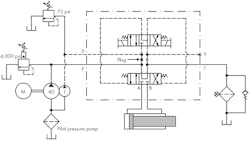

The hydraulic feeder circuit is fairly simple: It uses a 40-gpm pumping system with a 1-gpm pump for pilot pressure to reduce pilot-pressure heat generation when the cylinder is idle. A pilot-operated directional-control valve was sized large enough to keep pressure under 10 psi when its spool is centered. Both the relief valve and directional valve were mounted on a customer-supplied manifold.

The system ran fine for several years until a crane hook inadvertently caught hold of the pilot valve and ripped it off the main stage. As a result, the pilot valve was replaced with a new one.

The repaired system did not undergo any heat buildup during the idle phase, but a heating problem occurred when the system was cycling. If the system was allowed to idle for a period, its temperature would drop. Operators also noticed that the cylinder was operating at a slower speed.

Plant personnel called us in to add a heat exchanger to control the overheating problem. But we convinced them that they should resolve the problem rather than just treating the symptom.

They had already replaced both relief valves and used a flow meter to confirm that the pump output was close to the rated flow. We confirmed the cylinder was not bypassing.

Any idea what was causing the heat and slow cylinder operation?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by August 8, 2016 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Ryan Funk, of Peoria, Ill., who won our June puzzler by having his name picked from those who correctly answered that problem. A $50 gift card is in the mail to him.

Solution to Last Month’s Problem: Leaking Cylinder Puzzle Expert

After finding a puddle of oil under a forklift—even though no leak was found after a test run—I called in our seal provider. After we explained the circumstances, he told us, “The hardest thing to seal is a cylinder with NO pressure in it.” That was why we could not get the returned cylinders to leak when we tested them, and why the cylinder didn’t leak in the test run.

Our seal guy recommended that we stop using the factory seal kit the dealer was supplying us. Instead, we should use a different seal design made from a slightly softer material. It solved our leaking rod seal problem from that point on.

Looking for parts? Go to SourceESB.

This file type includes high-resolution graphics and schematics when applicable.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.