Troubleshooting Challenge: O-ring Installation Causes Motor to Overload

A student attending a basic hydraulic school at one of our distributors was having a problem with a hydraulic stamping machine at a metal fabricating plant. The plant’s maintenance people had replaced all of the O-rings on stack valves mounted on a manifold. When they started up the machine, the electric motor circuit driving the pump kept tripping from overload. He explained that the machine had worked fine for several years other than the recent problem of the O-rings leaking.

The student said a mechanic at the plant ordered a replacement motor, even though the machine was working fine before the new O-rings were installed. The new motor overloaded, just like the one removed by the mechanic. The maintenance people then considered installing a larger-horsepower motor, and the student told them he did not think it would solve their problem.

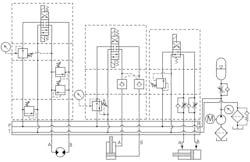

The student contacted us and asked if we could help troubleshoot the problem. We asked him for a copy of the schematic, shown above, and reviewed it with the class. The stack valves from Sun Hydraulics were all ISO-3 size, and worked with directional valves from Bosch Rexroth.

From the information given, can you determine why changing the O-rings would cause the motor to overload?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by August 29, 2016 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Mike Josefiak, mechanical engineer at Greenerd, Nashua, N.H., who won our July puzzler by having his name picked from those who correctly answered that month’s problem. A $50 gift card is in the mail to him.

Solution to Last Month’s Problem: Hydraulic System Overheats in Aluminum Recycling Plant

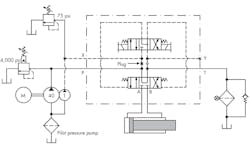

The aluminum recycling plant’s overheating problem was caused by the pilot-pressure relief system being connected to the main system pressure. The plug isolating the two pressure systems had an orifice hole through its center. This allowed the higher system pressure to force oil across the orifice and over the pilot-pressure valve, which was set at 75 psi.

Unfortunately, the pilot relief was a small, directly operated type, and its setting increases with flow. The orifice plug is normally supplied on internally piloted valves. Removing this plug increases the shifting speed of the main spool and can cause unwanted shock.

The orifice pressure drop, added to the pilot-relief setting, caused the heat buildup. Installing a solid plug in place of the orifice plug solved the problem.