Troubleshooting Challenge: Regenerative Circuit Not Working on a Molding Machine

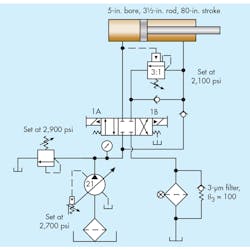

An older molding machine was being used to debug new dies. The opening and closing time for the machine had increased to twice its normal high-speed closing rate. However, the tonnage when clamped was still working fine.

The circuit used a Sun Hydraulics counterbalance valve as the regenerative unloader. Unfortunately, as is too often the case, the first thing the mechanic did was replace the pump, which didn’t solve the problem. Next, the Sun counterbalance valve was replaced. The maintenance people felt if they adjusted it as high as it would go clockwise, the high-speed regeneration circuit should work all of the time, and they would see half the normal tonnage. Again, this did not fix the problem. They disassembled the check valves and relief, but found nothing wrong.

Any idea what could be causing the problem?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by October 24, 2016 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Problem: Fix One Problem, Another Pops Up

After replacing a ruptured bladder in an accumulator, technicians could not get a pair of squeeze cylinders to extend, and when the cylinders retracted, a pressure gauge read 0 psi.

After the technicians received a new gauge, a lot of compressed air came out of the hydraulic line when they removed the old gauge. They installed the new gauge and bled any remaining air out by cracking the tube nut on the back of the gauge. Voila! The squeeze cylinders started extending.

One of the technicians made a comment that the tube lines to remote valves and gauges are usually ¼ in. or smaller in size. They summarized that the reducing valve’s balancing orifice passes only a small flow of oil, so it took a long time to compress the air in the oversized pilot lines—especially in the line to the gauge on the console. The air must have entered the ½-in. lines when the reducing valve was examined.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.