This file type includes high-resolution graphics and schematics when applicable.

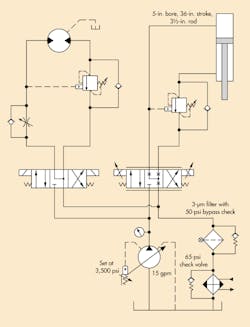

A distributor’s sales engineer asked us to troubleshoot a problem he was experiencing with a system he designed. We were not told what the machine did, but he gave us the schematic shown below.

The problem involved chattering that occurred every time the 5-in. bore cylinder extended to lower the load. He explained that if he adjusted the counterbalance valve to control the cylinder on its downward stroke when the proportional valve was wide open, everything worked fine. However, when he slowed the cylinder down with the proportional valve, it caused pronounced chattering, and he could not make any adjustment that worked.

Our work started by checking the model numbers of the components he was using. We determined that the pressure and flow ratings seemed to be sufficient for the application. We then turned our attention to the 30-gpm return flow when the cylinder was retracting. However, this had already been taken into consideration, so that was not the problem.

Next, we looked at the proportional valve, which had spool position feedback, even though it was not shown on the schematic. After some discussion, we ruled this out as a cause of the problem. The proportional valve had an asymmetric spool, which required the rod side of the cylinder to be connected to the B port, and it was connected as such.

Based on this information, what do you think was causing the chatter when lowering the load at less than full speed, and how would you resolve it?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by November 21, 2016, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Problem: Regenerative Circuit Not Working

Regenerative circuits rely on the oil from the rod end of the cylinder to flow to the cap end, which causes the piston rod to extend faster than in a conventional circuit. If left in this condition, though, the annulus area on piston’s rod side works against the area on the opposite side. The result is lower applied force from the cylinder.

To get maximum tonnage, oil from the rod side needs to be connected to a tank line. The Sun counterbalance valve adjustment is opposite that of most pressure controls, which increase pressure when rotated clockwise and decrease pressure when rotated counter-clockwise. The mechanic needs to adjust the Sun counterbalance valve counter-clockwise to increase the pressure. Unintentionally adjusting the Sun valve to open at a very low pressure prevented the regeneration feature from activating.