Download a PDF of this article.

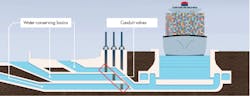

The recent expansion of the Panama Canal was an enormous task—one that required the resources of project partners around the world. A monumental feat of engineering and collaboration, the canal’s expansion included installing valves for the filling and emptying of a lock chamber system and establishing a system of water-saving basins and corresponding valves to control the water flow.

Since June 2016, ships up to 366 m (1,200 ft.) long and 49 m (160 ft.) wide can pass through this shortened connection between the Far East and commercial ports along the North American shoreline.

Two main players for this project were Bosch Rexroth and South Korean manufacturer Hyundai Samho Heavy Industries. Hyundai equipped and installed culvert, conduit, and equalization valves and appurtenant structures, while Bosch Rexroth supplied and built all operating machinery for the valves. This machinery includes custom-designed hydraulic power units (HPUs) with full redundancy, hydraulic cylinders, and comprehensive electronic control systems with sensors and backups, contributing to 99.9% reliability in all operating circumstances. The project required manufacturing 158 complete systems of hydraulic cylinders, HPUs, and controls in a synchronized effort from Bosch Rexroth workshops in the U.S., China, South Korea, Germany, and the Netherlands.

Above are hydraulic power units with stainless steel and flexible lines.

The Right Experience

Rexroth was chosen as system supplier for the valve drives and related control technology based on a number of factors. First, the company has decades of experience in civil and hydraulic engineering, including large engineering projects in Europe, South America, and China. Secondly, Bosch Rexroth has a rich history with the Panama Canal.

“We have worked with then Rexroth and now Bosch Rexroth since the early 1990s, and they have been a suitable technical solution provider for applications on locks, locomotive hydraulics, and programmable logic controls,” says Jorge L. Quijano, CEO for the Panama Canal Authority (ACP). “They have provided ACP with robust technical solutions and effective project management. They have been there to support our challenging needs both on the Panamax and Neo Panama canal locks.”

Here is a control block of a hydraulic power unit with pressure gauge.

Bosch Rexroth met with Panama Canal engineers in 1992 to explore how they could help upgrade the original mechanical lock machinery—in operation since 1914 when the canal first opened. Rexroth delivered a turnkey prototype project for rising stem valves, converting them from mechanical to hydraulic operating machinery. From there, Rexroth won a contract to convert all of the mitre gates from electromechanical to electrohydraulic, including computer controls and data acquisition. Based on these upgrades, canal engineers experienced the ease of control and reliability of an electrohydraulic solution, which resulted in Bosch Rexroth adding hydraulically operated systems.

Focusing on the Lock System

For the most recent project, awarded in 2010, attention turned to the canal’s two identical lock systems, one at the Pacific site and another at the Atlantic site. Because the system uses large amounts of water, the new advanced lock technology was designed to conserve water. Both new locks have three chambers, and each is connected to three water-saving basins. With this arrangement, it is by far the largest and most complex locks system in the world.

Each new lock has three lock chambers connected to a water-saving basin to recycle the water employed in a lockage from Gatun Lake.

As a ship travels from the Atlantic Ocean into a new lock, tug boats guide it into a lower lock chamber. As soon as the outer lock chamber gate closes, gravity fills the lower lock with water from the basins through the rising-stem valves. Main culvert valves then equalize the water levels of the middle and lower chambers. Once this occurs, the corresponding lock chamber gates open, and the ship can be tugged into the middle chamber. After the gates close behind the vessel to isolate the middle chamber from the lower one, the process repeats itself with the upper chamber.

Together, the three water-saving basins hold about 60% of the water volume to equalize each corresponding lock chamber. Therefore, only 40% of the water volume is lost by using the basins, saving water from Gatun Lake. When the ship reaches lake level, the outer gates open and it continues its journey through Gatun Lake to the Pacific Ocean.

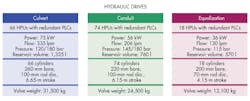

The hydraulic drives for all the valves are identical, but with different capacities for electric motors, pumps, valves, and reservoirs. The differences are caused by three types of cylinders for the culvert, conduit, and equalization valves. However, the software control system is the same for all the valves where the configuration parameters determine the type of valves.

Redundancy Is Key to 99.9% Availability

The lock system’s essential role in international transport requires near-perfect equipment reliability. Therefore, all systems have redundant operation. Technically, only two valves are needed to empty a basin. However, each basin has four valves. This means the lock will still continue working without issues even if two valves fail. The same redundancy exists for the culvert canal. Here, each lock installation contains 32 valves, but only half are needed for operation. This means the lock remains operational even when valve maintenance is being performed.

Every valve has a drive cylinder and related power unit, and each power unit has two motor-pump units (one being redundant). In addition, the PLCs and cylinder-position sensing systems of the valves also feature redundant design. The culvert, conduit, and equalization valves also have spares, so the complete scope of delivery comprises 158 drive units. This exhaustive redundancy contributes to a lock availability of 99.9%.

Every drive cylinder is equipped with a position measurement system that allows for the exact recording of the valve positions.

Time Constraints

Apart from the technical challenges of the project, time played a decisive role. Rexroth needed to develop 158 customer-specific HPUs and drive cylinders for the valve operation to regulate the water flow. These compensating valves control the inflow to the lock chambers and water-conserving basins. Once design of the hydraulic drives was complete, the first partial delivery to the Panama construction sites had to be fulfilled by January 2013.

Rexroth’s global development and production capabilities made this deadline achievable. Engineering and project management took place in Germany, and the hydraulic cylinders were developed in the Netherlands. Rexroth’s U.S. and South Korean plants manufactured the hydraulic power units and the cylinders were produced in China. Through all of the various locations and projects, everything had to conform to American Society of Mechanical Engineers (ASME) standards.

Parveen Gupta is vice president, applications & projects at Bosch Rexroth, Bethlehem, Pa.

About the Author

Leaders relevant to this article: