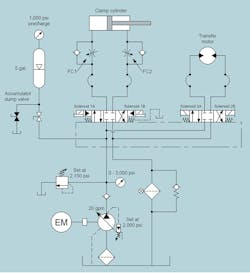

A company that makes concrete blocks has a carousel with 10 horizontal two-piece molds that are clamped together, one at a time, by a 3-in. bore, 15-in. stroke hydraulic cylinder. Concrete is then poured into the top gate to fill each mold. The clamp cylinder and mold are then moved to the next position on the carousel by a hydraulic motor. The circuit provided shows the transfer motor and only one of the 10 clamp cylinders.

No more than two mold clamp cylinders move at a time. One opens while the other closes. Once the mold that’s opening trips a position sensor, the motor turns the carousel. After a dwell time needed for the concrete to harden, that mold is opened and a block removed. The cycle then repeats unless someone trips a safety-light curtain.

A problem occurred when a freshly filled mold would open slightly, allowing concrete to leak from the bottom gap of the partially open mold. This happened when the carousel first started to rotate resulted in a rejected block because of the void created.

Any idea why the clamp cylinders didn’t always do their job?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. Bob and his company have been involved in troubleshooting, training, and consulting internationally for 30 years. All correct answers submitted by Nov. 16, 2019 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Challenge:

Press Mold Moving When it Shouldn’t

The bottom mold that occasionally moved as if it was losing clamping force only happened when a large pneumatic cylinder nearby was shifted and the propeller press started to open at the same time. The large cylinder caused the system supply pressure to drop when both were moving. Technicians installed a large-volume chamber in the supply line close to the press, and it solved the problem.