Bucher Differential Lock Valves Improve Machine Maneuverability and Energy Use

Bucher Hydraulics has developed the DL14 differential lock valves to help meet evolving mobile machine requirements, including reduced energy consumption. The valves are intended for use in hydrostatic drives with parallel-connected hydraulic motors in either open- or closed-loop mode.

Features of the DL14 differential lock valves include:

- bi-directional flow dividers enable forward and reverse travel

- optimized flow behavior for system efficiency

- orifice design enables large operating range at high pressures

- single size covers 100-250 l/min. operating range.

Higher Flow Rates and Efficiency Gains

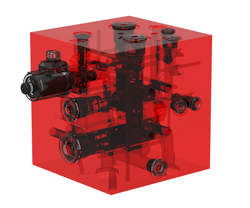

Bucher's DL14 differential lock valves are available for use with two-, three- or four-motor setups. Use in drive systems with more than four motors is also possible due to the valves' orifice being connected in parallel, the company said in its press release announcing the launch of the valves.

As the valves feature bi-directional flow dividers, their differential lock function can work during both forward and reverse travel. Bucher explained that when the differential lock is deactivated, the hydraulic flow distributes itself among the hydraulic motors freely, and with minimal pressure losses. This can help to improve overall efficiency and thus reduce a machine's fuel consumption. When the differential lock is activated, the hydraulic motors are operate with parallel connections.

The DL14 valve blocks are available with a 2- or 4-way differential lock function. The 2-way version suits flow ranges up to 250 l/min while the 4-way works with flows up to 500 l/min.

Optimization of the valve orifice design as well as its flow behavior enable use over a large operating range at high pressures. It can cover an operating range of 100-250 l/min with only one size necessary instead of the two valve sizes typically required to cover this range.

READ MORE: A Guide to Flow Control Valve Types and Use Cases

Design Features Enhance System and Machine Performance

Bucher designed the valve so it provides low pressure losses when the differential lock is deactivated and activated, enabling more wheel power to be available on a machine. As such, energy savings can be achieved when the lock is activated compared to what is possible with conventional spool-type flow dividers.

As the company explained, pressure loss with a 2-way differential lock is 5 bar at a nominal flow of 150 l/min and 11 bar at 250 l/min – and only 3 and 5 bar at those same points when the unit is deactivated. For the 4-way differential lock version, pressure losses are close to 56 bar less than alternative options when in the activated position with inlet flows of 100 l/min.

According to the company, these lower pressure losses equate to a hydraulic power savings of 9.3 kW.

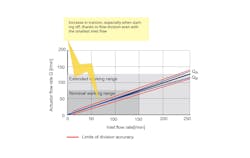

Further design features of the valves aid machine maneuverability. A locking effect occurs almost as soon as a machine begins to move, an aspect Bucher said its design team knew from the beginning it wanted to include. This was achieved through use of a metering orifice controlled by the incoming flow.

The diagram below shows how the division of the incoming flow begins from flow rates of less than 10 l/min. Bucher said this feature is especially beneficial in improving a machine's ability to move on slippery surfaces. It also helps operators remain focused on their work instead of trying to maneuver a machine through difficult terrain since it can more easily do so with less operator input. This features benefits forward and reverse operations as well.

Pressure compensators for each motor or actuator are integrated into the valve block as well to supply power to the wheel motors independently of load pressure. Continuous operating pressure of 450 bar can be achieved with the valves and a peak pressure of 520 bar.

The company notes there is a trend toward higher operating pressures in the mobile equipment industry, and the valves' ability to meet this need will benefit various OEMs. Bucher said the valves can be used in a range of machine types including agricultural sprayers, timber harvesters, aerial work platforms, road pavers and more.

In addition to the fuel savings it can provide traditional machines, the DL14 valves can also benefit hybrid and electric machines equipped with hydraulic travel drives due to their reduced energy use – key to optimizing run time of battery- and other electric-powered machines.