Ductile iron now available for large manifolds

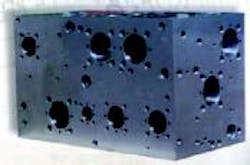

This manifold for a hydraulic press is 30-in. wide, 18-in. deep, and 20-in. high, a size that, until recently, was not readily available in ductile iron.

The benefits of ductile iron over other materials, such as steel, have been well documented for years. Ductile iron has found favor in a wide variety of applications due to its easy machinability, high sound and vibration damping abilities, and high strength, wear resistance, fatigue strength, ductility, and toughness. But size limitations meant that ductile iron could not be used for very large hydraulic manifolds. Consequently, they had to be made using alternative techniques, such as steel plate or forgings.

Both of these alternatives usually led to more costly manifolds. Now, however, ductile iron is now available as Unibar continuously cast bar. Available in four grades, Unibar comes in rough-machined ingots with a 191/23 231/2-in.cross section and standard lengths to 39 in. All ingots and blocks are ultrasonically tested to ensure internal soundness. Submitted by Chuck Rigali, United Cast Bar Inc., Aurora, Ill. For more information, contact United Cast Bar Inc. at (630) 897-7811 or visit www.unitedcastbar.com.