This file type includes high resolution graphics and schematics when applicable.

The primary function of hydraulic reservoirs is to temporarily store hydraulic fluid. If properly designed, they can also function as fluid-conditioning devices. That is, they not only provide fluid to meet varying demands as actuators extend and retract, but can also prepare the fluid for its next working cycle.

Design Considerations

Mobile-hydraulic reservoirs are expected to perform as well as industrial reservoirs, even though the mobile variety typically operates under more extreme and often adverse conditions. Two examples of the special problems faced by designers are machine motion and extreme ambient temperatures. However, the most significant problem to overcome is the limitation in size.

Size is the most striking difference when comparing industrial and mobile designs. Industrial standards, developed by NFPA (National Fluid Power Association) and accepted by ANSI (American National Standards Institute), specify that reservoir capacity should equal three to 12 times maximum pump output. However, size and weight limitations may require the equipment to operate with reservoirs as small as the volume the pump discharges in a single minute. Because of the special limitations of mobile hydraulic reservoirs, they typically require custom design.

Custom-made hydraulic reservoirs have an advantage over off-the-shelf reservoirs because they can be designed to fit the exact space and technical requirements necessary for optimal performance. Cost, size, and weight can be minimized while maintaining performance and efficiency. 3D modeling can be used to develop the most efficient design for the application and for manufacturability. A design that is too complex of a design makes manufacturing more complicated, which increases cost. Here are some factors to consider:

Calculating drawdown: The amount of fluid a reservoir must make up is equal to the total drawdown—the areas of the cylinder rods multiplied by their respective strokes. The sum total of all these volumes equals the volume of fluid the reservoir must provide.

Drawdown calculations are critical: enough fluid should remain in the reservoir at maximum drawdown to provide a reasonable residence time for the fluid passing through the tank. Residence time gives the contaminants a chance to settle out and air bubbles to coalesce. A good rule of thumb is to fix total capacity at one-third of maximum pump output at drawdown.

Thermal expansion: Increases in fluid volume from heat must be considered when sizing a reservoir. Fluid expansion between the time a reservoir is filled with cold fluid and when the fluid reaches maximum operating temperature must be accounted for. Care should be taken to avoid overfilling when servicing reservoirs. Reservoir oil levels should be checked with all cylinders retracted. To calculate thermal expansion, use a co-efficient of volume expansion of 4.5 x 10-4. The co-efficient multiplied by the volume in cubic inches of fluid undergoing the temperature change and the change itself in degrees will yield the volume change due to heating or cooling.

Vented or pressurized: Should a vented or pressurized reservoir be specified? The key deciding factors are the location and inlet requirements of the pumps. In many mobile applications, the fluid level of the reservoir is below pump inlet. In response to pump inlet line losses, the pump may cavitate–i.e., form small liquid-free zones such as bubbles or voids. Collapsing voids that implode near to a metal surface cause cyclic stress through repeated implosion. This results in surface fatigue of the metal, causing cavitation. Because an inlet vacuum may require pump de-rating, the reservoir can be pressurized to maintain maximum pump performance.

Three techniques are used for pressurizing a reservoir on most mobile construction equipment:

• Use regulated compressed air from the machine’s pneumatic system. This is probably the most eï¬ective way.

• Contain the air within the reservoir clearance volume (above the fluid) and depend on thermal expansion of the fluid to compress the air and pressurize the reservoir.

• Tap pressurized air from the scavenge pump of a two-cycle diesel engine.

A reservoir pressure cap ensures that pressure is contained within the tank and relieves excess pressure when the cylinders are retracting, so it returns more oil to the tank than the pumps are demanding. The cap must also have low pressure-overshoot characteristics.

When a reservoir is pressurized, its wall stresses must be calculated. However, wall stresses should also be calculated for a vented tank. High stresses develop quickly in large areas of flat plate, and deflections can become large due to the weight of the fluid. If peripheral equipment such as ladders or air tanks are added to reservoirs, plate thickness and the need for stiffeners should be considered.

Careful placement of baffle plates can provide needed support without costly additional weight. Mounting brackets and access cover mounting flanges can also provide stiffness when carefully placed.

Inlet and Return Lines

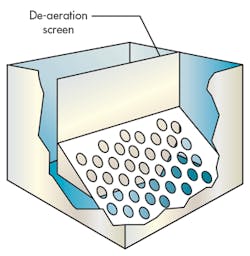

Small bubbles of air entrained in the fluid when drawn through a pump become pressurized and implode, rebounding a jet of fluid outward at pressures in excess of 50,000 psi, along with extremely high local temperatures. These fluid jets can chip bits of metal from surrounding surfaces. Screens of expanded or perforated metal, called de-aeration screens, placed in the reservoir at an angle are effective in removing air bubbles from fluid (Fig. 1). When fluid containing air bubbles is directed through the angled screen, the bubbles travel up the ramp formed by the screen while the fluid passes through. Care must be taken when selecting the angle and the amount of open area to ensure the passage of cold fluid.

A smooth transition should occur from the low velocity of the fluid in the reservoir to the pump inlet lines. Velocities in pump inlet lines should not exceed 5 ft./sec. in large lines. For any given flow velocity in two different size lines, pressure drop is greater in the smaller line because of increased fluid shear area. Cutting the end of pump inlet lines inside the tank at an angle and pointing the mouth downward provides a larger throat area and helps prevent fluid vortexes (small whirlpools) and cavitation. Locate the inlet tube under a substantial depth of oil to avoid vortexes, or add vanes to the throat of the tube extending outward.

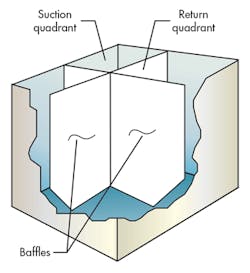

Baffles direct, diffuse, and contain fluid and increase tank stiffness (Fig. 2). To help cool return fluid, it should be directed toward the outer walls of the reservoir. The fluid should also flow across magnets, which intercept ferrous particles. Return flow should never be aimed at a fluid intake line.

Some fluid mixing without agitation is beneficial. Diffusing the fluid throughout the tank prevents dead spots, where fluid can collect. Flow velocities across any baffle should be 1 ft./sec or less. Fluid must not cascade from one level to another within the tank. This can be caused by differences in fluid levels between two areas separated by either a poorly designed baffle or multiple-level tank bottom.

When sizing baffles—or any component in the return portion of the tank—provide for maximum return flow. Assume that the cylinder of the largest area ratio (cylinder cap-end area minus rod-end area) is being retracted at full flow: return flow will exceed pump output. Return diffusers and filters should also be sized to accommodate this flow.

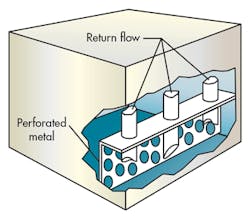

Return-line velocities on mobile equipment usually exceed 10 ft./sec. It is best to size return manifolds and plumbing adjacent to the reservoir to reduce return velocity to 5 ft./sec or less. Return-line diffusers help reduce flow velocities and provide fluid mixing without agitation. Diffusers commonly reduce flow velocities to 1 ft./sec. or less.

Many types are commercially available. However, fitting the ends of return lines with 40%-open-area perforated metal works well (Fig. 3). When possible, return lines should have ends cut at 45 deg. and be directed toward an exterior wall.

Contamination Control

Return filters are often placed inside the tank to save space and provide integral diffusion. One advantage of in-tank return filtration is that filling the tank through the filter helps ensure fluid cleanliness. However, be sure to install return filters so that contaminants will not fall into the reservoir when an element is changed.

Placing filters within the tank provides a neat-looking design, but may introduce contamination to an area where it is difficult to remove. External return filters, while more difficult to plumb, keep contamination outside the tank and are more easily accessible for servicing.

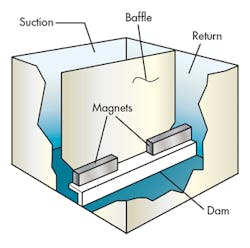

Particle dams (Fig. 4) placed between the return and suction areas of the tank help contain heavier particles that may have bypassed the return filters. Dams commonly consist of an angle plate that extends across the floor of the tank. The dam should be high enough to contain particles until the reservoir is routinely cleaned and low enough to prevent cascading. Dams also provide ideal mounting surfaces for magnets.

Pumps in mobile equipment are usually located at or above fluid level and far away from the tank. These conditions sometimes create a high inlet vacuum (greater than 5 in. high), which complicates pump inlet contamination control. Suction strainers or inlet filters should be considered where positive pump inlet conditions exist (as with a charge pump). Cold startup and ambient operating conditions should also be considered when sizing suction filters if pumps cannot be disengaged during startup.

Materials of Construction

Hydraulic reservoirs in mobile equipment can be prone to corrosion when humid air is drawn in when the oil level drops. Once moist air gets into the reservoir, water can condense on the interior walls when the ambient temperature drops. Desiccant breathers can be specified to filter and dry ambient air drawn into the reservoir. However, the desiccant has a finite service life, so if the breather is not changed at recommended intervals, moisture will be drawn in unimpeded. The condensate, ultimately, will enter the hydraulic system and pose several problems.

The condensate will also adhere to the interior surfaces of the reservoir, which could lead to rust deposits that can also enter the hydraulic system. These deposits can cause problems of their own, including premature wear to components, clogging of filters and orifices, and valve malfunctions.

Mobile hydraulic reservoirs are typically manufactured from steel, stainless steel, or aluminum. Another option is aluminized steel. Aluminized steel is sheet carbon steel that is hot-dip-coated on both sides with an aluminum-silicon alloy to avoid the contamination problems inherent to uncoated steels (Fig. 5). Essentially, aluminized steel combines the corrosion resistance of aluminum with the high mechanical strength — and lower cost — of steel. Aluminized steel reservoirs are compatible with virtually all petroleum-based and synthetic fluids while also providing protection from atmospheric corrosion. However, aluminized steel has thickness limitations.

Fabrication and Finish

The quality of the weld is all-important for any hydraulic reservoir. A combination of MIG, TIG, and robotic and electrical resistance welding should be expected from any manufacturer to provide reservoirs of the highest quality. Manufacturing equipment should also include CNC turret, FMS and LNC lasers, punches, CNC forming equipment, and CNC welding equipment.

Powder coating should be seriously considered for finishing (Fig. 6). The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a “skin.” It creates a hard finish that is tougher than conventional paint. Increasingly stringent environmental regulations, rising costs in all areas, and demands for better quality and more durable products make it the smart choice for a better-looking, more durable finish.

Final Considerations

Reservoir servicing must also be taken into account. Provisions must be made to drain both return and suction areas of the tank, especially if a dam is used to separate them. Pipe couplings are often used, but SAE O-ring ports provide better sealing. Valves should be provided to close off inlet lines when replacing pumps or other components that are below fluid level.

Furthermore, access must be provided for cleaning the interior of the tank. Hatches should be large enough for service personnel and cleaning tools. There should also be a means for lighting each portion of the tank for inspection. Hatches should be attached to the tank so leaks can be detected and repaired from the outside.

When mounting the reservoir, consider the dynamic nature of the mobile equipment; bouncing over rough terrain or moving at highway speeds can put high impact or fatigue loading on tank walls. When mounting a tank by the corners, stresses can be distributed through the side plates by placing angles in the corners.

All reservoirs should be delivered clean and pressure-tested. The manufacturer should be able to provide powder coating and chemical-agent-resistant coatings and sub-assemblies. In fact, manufacturers that can install accessories—fill caps, filter breathers, sight gauges, sending units, hoses, fittings, and mounting hardware—simplify the procedure by providing equipment that can readily be installed into the machine.

Keith Ellefsen is president of The IFH Group, Rock Falls, Ill. For more information, call (800) 435-7003 or visit the company's website.