Fluid Power eBook, Edition 2, Chapter 1: Accumulator Circuits - Part 1

Hydraulic accumulators make it possible to store useable volumes of non-compressible fluid under pressure. A 5-gal container completely full of oil at 2000 psi will only discharge a few cubic inches of fluid before pressure drops to 0 psi. The same container filled with half oil and half nitrogen gas would discharge over 11/2 gal of fluid before pressure dropped to 1000 psi.

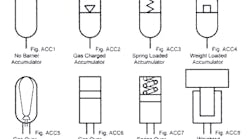

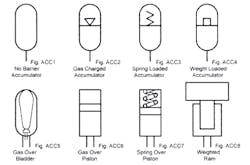

Figures 1-1 through 1-4 show symbols used for different types of accumulators. Figures 1-5 through 1-8 are simplified cutaways showing construction of different types of accumulators.

All accumulators except Figure 1-4 will have a pressure decrease as fluid discharges. A weight-loaded accumulator maintains pressure until all oil is used.

When using an accumulator, it is necessary to install a manual or automatic function to de-pressurize all fluid before working on the circuit. Several manufacturers make automatic discharge valves that work well. These automatic discharge valves are explained at the end of this section.

Most hydraulic accumulators are used in one of four applications: 1. Supplement pump flow in circuits with medium to long delays between cycles. 2. Hold pressure in a cylinder while the pump is unloading or stopped. 3. Have a ready supply of pressurized fluid in case of power failure. 4. Reduce shock in high velocity flow lines or at the outlet of pulsating piston pumps.

The following circuit images show some circuits using accumulators for the operations mentioned in 1 to 4 above. Other accumulator circuits and information follow.

Using accumulators to supplement pump flow

Some hydraulic circuits require a large volume of oil for a short time; for example to move a large cylinder rapidly to clamp a part. After clamping, the circuit needs little or no additional fluid for period of time while curing takes place. When a circuit has extended dwell time, an accumulator can be used to downsize the pump, motor, tank, and relief valve. The cost of accumulators usually offsets savings on these smaller components, but downsizing saves on operating costs.

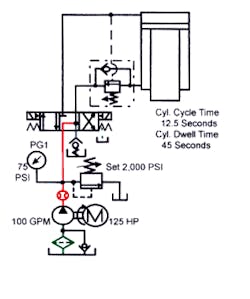

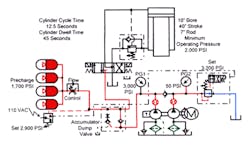

The conventional pump, directional valve, and cylinder pictured in Figure 1-9 show horsepower and flow requirements needed for a 12.5 sec cycle time. The advance cycle requires full power, while returning the cylinder needs minimal force. Reduction of the pump and motor size is not possible if the cylinder cycles rapidly. However, if there was a 45 sec wait between cycles, the pump and motor could be almost 70% smaller with an accumulator circuit.

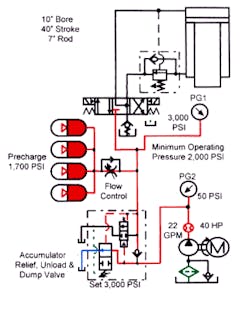

This reduced flow and horsepower are possible when using accumulators and the circuit shown in Figure 1-10. The extra expense of the accumulators offsets the reduced price for the power unit, but operating cost is less for the life of the machine. The directional valve and piping from the accumulators to the cylinder still has to handle the 125 gpm flow.

Using a gas charged accumulator in a pump supplementing circuit will increase maximum system pressure. The extend portion of the cycle needs at least 2000 psi working pressure, which requires filling the accumulators with fluid above 2000 psi so they can discharge oil and not drop below minimum pressure. The maximum system pressure should be as high as can be tolerated. The higher the maximum allowable system pressure, the smaller the accumulators. The drawback of high pressure is that the circuit is at this pressure when the cycle starts. If this higher pressure can cause damage or other problems, it should be lowered to a safe level.

Accumulator circuits normally have flow controls because there is a volume of oil at elevated pressure that can discharge almost instantaneously. Placing a flow control at the accumulator outlet allows free flow from pump to accumulator and adjustable flow to system.

The circuit in Figure 1-10 has a minimum pressure of 2000 psi and a maximum pressure of 3000 psi. This pressure is the limit of most hydraulic components. A 22-gpm pump driven by a 40-hp motor now meets the force and cycle time specified. All pump flow continuously goes to the circuit instead of being unloaded most of the time as in conventional circuits.

As the cylinder cycles, the accumulators supply fluid at a rate set by the flow control. Pump flow adds to accumulator flow to set the required cycle time. Cylinder cycling could be made faster than specified by increasing outlet flow from the accumulator.

The fixed-volume pump in Figure 1-10 unloads through a special accumulator relief/unload/dump valve, which sends all pump flow to the accumulators and cylinder until the system reaches set pressure. After reaching set pressure, the valve opens and unloads the pump to tank at approximately 50 psi. The pump will continue to unload until the system pressure drops about 15%. This pressure drop might be from leakage or at the start of a new cycle. Any time pressure drops, the pump will load and stay loaded until pressure tries to go above 3000 psi. With this valve, stored oil in the accumulators automatically discharges to tank when the pump stops, which makes the circuit safe to work on shortly after locking and tagging off the pump.

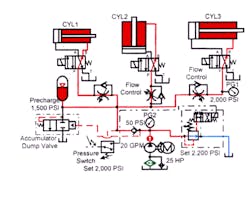

Figure 1-11 shows a variation of the accumulator circuit in Figure 1-10. Here a 1-gpm fixed-volume pump and a 5-gpm pressure-compensated pump supply oil until the accumulators fill. A pressure switch, set at about 2900 psi, unloads the fixed-volume pump through a solenoid-operated relief valve. After the fixed-volume pump unloads, the pressure-compensated pump finishes filling the accumulators and holds maximum pressure without fluctuations and with minimal heating.

The accumulator dump valve in this circuit will stay closed as long as the pumps are running. When the pumps stop, this valve quickly and automatically discharges the accumulators to tank.

Full-time pressure with fixed-volume pumps

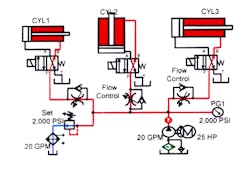

Some circuits need pressure at all times to hold position or maintain force. The circuit in Figure 1-12 holds pressure on the cylinders when they stop, but excessive heat generation makes it a poor choice. Flow controls keep pressure in the circuit while a cylinder is moving.

Some designers use the circuit shown in Figure 1-13 to simultaneously reduce energy loss and maintain holding pressure. This double-pump circuit provides high flow (to move the cylinders rapidly) and low flow (for pressure holding). While the system is at holding pressure, the high-flow pump goes to tank through an unloading valve. Only the low-flow pump goes across the relief valve. Although energy loss is drastically reduced, it is still excessive.

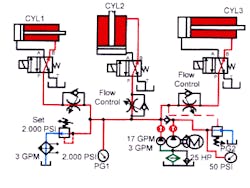

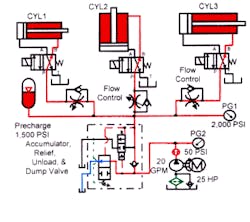

The circuits shown in Figures 1-14 and 1-15 use a small accumulator to hold pressure on the actuators while unloading the pump at minimum pressure. This makes it possible to use a less expensive fixed-volume pump instead of a pressure-compensated pump, with little or no energy loss or heat generation.

The pump in Figure 1-14 unloads through an accumulator relief/unload/dump valve. This valve sends all pump flow to the accumulator and cylinders until the system reaches set pressure. After it reaches set pressure, the valve opens and unloads the pump to tank at approximately 50 psi. The pump will continue to unload until the system pressure drops about 15%. This pressure drop might be from leakage or it could be at the start of a new cycle. The pump loads again and fills the circuit until pressure tries to go above 2000 psi. While the pump unloads, the accumulator makes up for any leakage so pressure at the cylinders only drops about 15% maximum. The length of time the pump unloads depends on the size of the accumulator and the amount of system leakage. With the accumulator relief/unload/dump valve, stored oil in the accumulator discharges to tank when the pump stops. This makes the circuit safe to work on shortly after locking and tagging out the pump.

Notice the variation of the above pressure holding circuit in Figure 1-15. Here the pump unloads through a normally open, solenoid-operated relief valve controlled by a pressure switch. The accumulator and actuators fill from the pump until system pressure reaches 2000 psi. At 2000 psi, the pump unloads through a solenoid operated relief valve at approximately 50 psi. The main advantage of the circuit in Figure 1-15 is that pressure drop is adjustable by more or less than the fixed 15% allowed by the unloading valve in Figure 1-14.

To have a safe accumulator circuit, it is necessary to have a means to discharge stored energy at shutdown. The circuit in Figure 1-15 uses a high-ratio pilot-to-close check valve. The pilot ratio is about 200:1, which means 25 psi in the pilot line can hold as much as 5000 psi in the circuit. Most unloading circuits have at least 25 psi while unloaded, so this valve works well. When the pump shuts off, pressure drops to zero, the pilot-to-close check valve opens, and stored energy dumps to tank.

Another way to automatically discharge the accumulator at shutdown is with a normally open, solenoid-operated, 2-way directional valve. This directional valve connects to the accumulator pressure line and on to tank. Starting the pump motor also energizes the solenoid on the normally open 2-way valve, causing it to close. As long as the pump runs, this valve blocks the flow path to tank. When the pump stops, the solenoid is deenergized, and the valve shifts to port stored energy to tank.

CAUTION! ALWAYS CHECK AN ACCUMULATOR CIRCUIT FOR PRESSURE BEFORE WORKING ON IT. NEVER ASSUME THE AUTOMATIC UNLOADING SYSTEM WORKED!