Industries requiring high force pressing have relied on hydraulics for many years. However, the hydraulic fluid leaks which sometimes occur can cause contamination and safety risks for many applications.

In these instances, many are turning to electromechanical actuators for a leak-free alternative. This was the case for a whiskey barrel manufacturer who was experiencing hydraulic fluid leaks that led to reductions in output and productivity.

The manufacturer worked with Tolomatic to replace its hydraulic pressing equipment with all-electric machines, enabling it to minimize downtime and product waste previously caused by leaks as well as achieve performance improvements.

Barrel Making Requires High Force Capabilities

The manufacturer constructs whiskey barrels from oak staves, which are gathered together and bound by a metal ring that is pressed onto the stave bundle.

During the manufacturing process, the press indexes down while arms extend from the side, locking the barrel in place. Then, the press pushes tooling against the metal hoop. After the metal ring is applied, the arms expand and the barrel is rotated for the process to repeat once more.

Because pressing the metal ring onto the barrel requires a high amount of force, the manufacturer initially used hydraulic presses.

Unfortunately, whenever hydraulic fluid leaked from the system and dripped onto the barrel, the entire barrel had to be discarded. Not only did this reduce product throughput, but the downtime required for repairs also impacted the operation.

The barrel manufacturer found an alternative with electromechanical presses as a leak-free solution without sacrificing performance.

Traditionally, electromechanical actuators have had force limitations that kept them out of some high-force end pressing applications, but the force capabilities of linear servo actuators continue to grow. Today, linear servo actuators can match the forces of similarly-sized hydraulics — and do so with better energy efficiency and force control.

Replacing Hydraulics with Electric Actuators

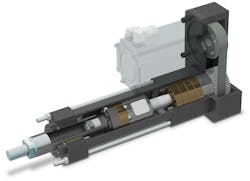

The new pressing system chosen by the barrel manufacturer uses two linear servo roller screw actuators that operate in tandem. Each actuator features an alignment coupler that connects to a plate attached to the 2,000-pound annular-shaped tooling. By pushing the plate up and down, the actuators press the tooling into the metal ring so it can squeeze around the barrel staves.

The barrel manufacturer specified two RSX 15 actuators from Tolomatic for the new system, each supplying 17,450 pounds of force. With a combined force of 34,900 lbs., the actuators travel a stroke length just over 20 in. (508 mm).

While the manufacturer chose to replace its hydraulic system with two electric actuators, Tolomatic also offers actuators that could have accomplished the same results with a single model. A two-actuator setup was chosen because the barrel manufacturer had worked with another company previously to design the machine with two actuators and did not want to have to do a complete redesign for a single actuator solution.

In addition, splitting the load across two actuators has the potential to extend the overall life of the system.

Electric Actuators Enable Motion Profile Improvements

With the previous hydraulic system, the manufacturer had a fairly fast and aggressive motion profile. To match this profile with electric actuators, a static oil bath was installed around the roller screws, reducing heat generated by friction.

The electric components matched the cycle speed requirement and optimized the motion profile to accommodate a complex multiple-hoop press. With electric actuators, the manufacturer improved the coordination and efficiency throughout the entire system.

Even though hydraulic actuators provided enough force to meet the manufacturer’s needs, throwing barrels away due to hydraulic fluid contamination and production losses caused by downtime were becoming a problem. The high power density of roller screw actuators allowed the manufacturer to achieve application success and also maintain high throughput.

This article was written and contributed by Matt Gulleen, Application Engineering Manager, Tolomatic.