The How and Why of Magnetic Force Feedback

What you’ll learn:

- What magnetic force feedback is and how it works.

- The advantages of magnetic force feedback over traditional solutions.

- How to use magnetic force feedback effectively.

- How magnetic force feedback is used in a multitude of applications.

Magnetic force feedback is the next evolution of force feedback control and is being developed by Iris Dynamics, a manufacturer of intelligent linear electric motors. The core technology is an electromagnetic control system that manipulates magnetic fields to control position, acceleration and most importantly the force of an actuator.

This method of force feedback has the ability to transform industries by enabling high fidelity feedforward and feedback when interacting with systems that require fast response and sensors integrated directly into the motor. This type of control is far superior to the traditional technology that makes use of inaccurate gear trains and servo motors.

READ MORE: Getting the Right Stepper or Servo Motor for Electric Actuators

How Does Magnetic Force Feedback Work?

The mechanical operation of magnetic force feedback is elegantly simple. The device consists of a thin walled stainless steel tube lined with permanent magnets. This shaft assembly is then placed inside an array of copper coils, a current is passed through these coils, and an electromagnetic flux is created.

This flux is manipulated by the control software, which in turn generates complex waveforms that move the shaft in predictable ways. The high speed and force capabilities can be accurately controlled to produce complex feedback to the user that can create ultra realistic force feedback.

Advantages of Magnetic Force Feedback

Magnetic force feedback has a number of advantages over its traditional electromechanical counterparts, some of which are:

- silent operation

- one moving part

- integrated force sensing and control

- integrated position sensing and control

- fast response times

- can be linked with software

- low voltage DC power

- low cost comparable to other systems.

Like any complex control system, there exists inherent undesirable effects that reduce overall system efficiency. Traditional systems usually design around these effects creating complex mechanical systems that have multiple points of possible failure. With magnetic force feedback, these issues can essentially be programmed away.

In a magnetic system, issues such as magnetic hysteresis, torque rippling and bearing friction can create large enough errors to ruin the immersion and realistic feedback to the user. However, with magnetic force feedback, these issues can also simply be removed programmatically.

Closed Loop Control

In control systems engineering, there are a number of ways of controlling a motor. Generally speaking the most accurate method involves a closed loop system where the actual output can be measured compared to desired output and adjusted as needed. Closed loop control necessitates having a method to sense output.

READ MORE: Designing closed-loop circuits for stability

In the case of a device that is force controlled this means the inclusion of a load cell, a type of external sensor which can measure the amount of force (pressure) being exerted between two objects. These sensors are delicate, expensive, and generally require sophisticated high speed external amplification controllers before feeding their measurements back to the closed loop motor controller.

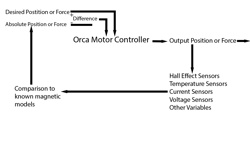

Magnetic force feedback eliminates this complexity by comparing known magnetic models and comparing them using an integrated array of hall effect sensors, temperature sensors, current sensors, voltage sensors, and other magnetic variables to interpolate absolute positional and force data. This approach results in a more accurate, more compact, simplified, and an ultimately faster device. Having a faster device means that more complex effects can be generated.

Applications of Magnetic Force Feedback

Due to the high accuracy and high speed of magnetic force feedback, developers can program more sophisticated effects into their system. The true value of the technology can be realized when generating subtle effects and queues that are traditionally very difficult to replicate in a simulated environment.

Magnetic force feedback allows subtle vibrations, displacements, and dampening forces to be programmed. In an entertainment application for example, this makes a clear difference in the immersive nature of the experience. In a training scenario, the trainee has both better immersion and can develop better muscle memory. By pushing the envelope of immersion a more believable and engaging experience can be delivered be it to an amusement park guest or to a pilot learning a new skill.

Magnetic force feedback offers an improvement over existing force feedback technology. With precise and high speed sensing, integrated position and force control, closed loop control, and a simple, fully integrated design, magnetic force feedback systems are changing the way we interact with machines. From training and simulation to high precision industrial applications, magnetic force feedback is the next evolution in robotics.

This article was written and contributed by Iris Dynamics LTD. It originally appeared on the company's website.