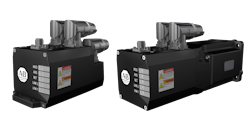

Rockwell Automation Distributed Servo Drives Allow for Smaller Machine Designs

The ArmorKinetix Distributed Servo Drives from Rockwell Automation can be mounted outside of an electrical cabinet, allowing a more simplified architecture.

Key features of the servo drives include:

- design flexibility and reduced component requirements

- power output up to 5.5 kW

- IP66 certification to ensure durability

- integrated vibration and thermal sensors for performance monitoring.

READ MORE - How Advanced Servo Technology can Take Motion Systems to the Next Level

Benefits of a Distributed Servo Drive System

The ArmorKinetix Distributed Servo Drives are designed for mounting directly on a machine instead of in an electric cabinet. This enables creation of a smaller overall machine footprint as well as a reduction in cabling and cooling requirements. Use of smaller electrical cabinets is also possible to improve space utilization in a facility.

Per Rockwell Automation, moving to a decentralized system such as the ArmorKinetix drives can reduce cabling up to 90% while lowering overall system costs by about 30%. For the latter, the ability to use smaller machines and electrical cabinets combined with the reduced cooling needs enables can lower energy use for improved operational costs.

The servo drives are available in Distributed Servo Drive (DSD) and Distributed Servo and Motor (DSM) formats to meet a range of motion control applications, providing greater design flexibility for machine manufacturers and their customers. Both types require fewer parts and terminations to help create a compact unit while also reducing installation time.

In addition to the design benefits offered by the servo drives, they also provide the ability to improve maintenance for machine owners. Vibration and thermal sensors are integrated into the drives to help detect potential issues which can be addressed before a costly downtime event occurs.

Additional benefits provided by the ArmorKinetix Distributed Servo Drives include:

- optimized power density with minimal derating

- integrated safety technology capable of achieving SIL 3

- CIP Security capability

- easier support and intuitive operation.