Oilless pneumatic systems have been in the norm for some time because they don’t require lubricators, oil, and periodic maintenance. But the fact remains that the majority of pneumatic systems are lubricated.

That’s because many users deem the total savings from lubricated air exceed the cost of installing and maintaining the lubricators. Lubrication helps reduce friction between sliding surfaces, and that improves efficiency and permits higher operating speeds. It also reduces wear, which ultimately means longer component life and less maintenance. Moreover, lubrication in pneumatic systems can reduce both internal and external leakage around valve spools, cylinder rods and pistons, and air motor and rotary actuator vanes, rotors, and housings.

That said, a major drawback to lubricated systems is they discharge oil mist when the air exhausts. And that can bring the unwanted attention of regulatory authorities.

Discharge regulations

The Occupational Safety and Health Administration (OSHA) Air Contaminants Standard 1910.1000 mandates employees’ exposure limits to toxic and hazardous substances. For oil mist, compressed air exhaust may not contain more than 5 mg/m3 (about 4.3 ppm) on a time-weighted average basis. The standard also details how to calculate total risk when a worker’s exposure varies throughout the day.

Likewise, the National Institute for Occupational Safety and Health (NIOSH) recommends short-term exposure limits of no more than 10 mg/m3, defined as a 15-minute exposure that should not be exceeded at any time during the workday.

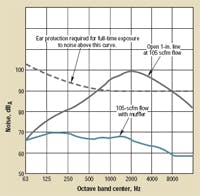

In addition to oil-mist limits, regulations govern noise levels of compressed air exhaust. OSHA Standard 1910.95 on occupational noise, in short, limits a worker’s average noise exposure in an eight-hour day to 90 dB, and less than 15 minutes at 115 dBA.

Obviously, most every manufacturer strives to keep its plant safe for workers. Failing to comply with the standards can result in considerable costs and headaches for a company. In addition to potential fines and penalties, operating outside the recommended limits can bring requirements for respirators and hearing protection for employees, ongoing monitoring of noise levels and air quality, annual company-paid medical check-ups, and onerous paperwork and record keeping. And that’s not to mention the unpleasant prospect of a government inspector lurking behind your back.

Two-in-one solution

In a nutshell, routing noisy and oily compressed air into plant can be a real problem. Fortunately, there’s a simple solution to the problem — air exhaust mufflers that reduce noise and also limit emissions of oil and dirt. These products go by a number of names, including coalescing mufflers, coalescing silencers, filter silencers, and reclassifiers.

Regardless of name, manufacturers state that these products easily bring pneumatic systems into compliance with government regulations. Internal geometry of the devices reduces air velocity and baffles for audio damping take care of noise; filtration takes care of the oil. But just any filter-muffler may not suffice. A standard filter-muffler has a porous element to trap solids entrained in the compressed air stream, but it is not designed to trap oil vapors.

A coalescing muffler, on the other hand, operates on the same principles as a coalescing filter. As air flows through the coalescing element, oil particles are captured by three different mechanisms: direct interception, inertial impaction, and diffusion. In direct interception, oil particles simply collide with and are trapped by filter fibers. With inertial impaction, the element’s turbulent air stream throws oil particles against fibers, which trap the oil. Diffusion causes the smallest particles to vibrate and collide with each other - and eventually the element’s fibers - which trap the oil.

However, because these devices are on the exhaust side of a pneumatic system they are exposed to sudden shock loading. This means their oilremoval capabilities may not be as consistently good as those of a pure coalescing filter.

Nonetheless, a good coalescing muffler typically gives 2 ppm or less oil discharge in normal operation. (Without coalescing mufflers, contamination may exceed 50 ppm in a plant that is tightly closed for operation in cold weather.) Most also have a port for draining collected oil, and elements that can be changed without having to replace the entire muffler.

Whatever the choice, mufflers that remove oil from the exhaust air should be considered - especially if air exhausts near workers. It is not uncommon for coalescing mufflers to remove 99.97% of the entrained oil. Even if oil-free compressors are used, exhaust mufflers can reduce noise to OSHA-acceptable levels and ensure that exhausted air is clean.

Guide to available products

The Atomuffler defogger/reclassifier muffler from Allied Witan is one device designed to reduce pneumatic noise from air-operated devices and effectively remove entrained oil from exhausted air. The muffler uses a proven coalescing concept of intercepting, extracting, and condensing oil to liquid droplets that gravitate into a sump to be drained off periodically. And it reduces objectionable noise and particulate contamination associated with pneumatic systems.The corrosion-resistant defogger/reclassifier mufflers are rated for pressure to 125 psig (8.6 bar) and come with disposable disseminator elements. They are available with male pipe thread connections (NPT) in nine standard sizes from 1/8 to 2 in. for quick connection to exhaust ports.

Bosch Rexroth’s MU1 oil separator with silencer has a three-stage coalescing micro-filter. Filter efficiency is reportedly 99.99% with remaining oil content in the discharge air as low as 0.01 mg/m3. The company recommends replacing the filter element annually.

Reclassifying mufflers from Exair help plants meet OSHA requirements by reducing sound to safe levels below 90 dB. In most installations, the typical noise reduction is up to 35 dBA. In addition, they separate oil from the exhausted air so virtually no oil is released into the environment. For instance, based on an intake of 50 ppm at 100 psig, the reclassifying muffler reportedly reduces exhausted oil mist to 0.015 ppm. A reservoir where oil accumulates at the bottom of the unit can be drained by attaching a ¼-in. tube. Connector sizes range from 0.12 to 1.0 in. NPT.

clean the exhaust air from pneumatic control systems via a fine filter cartridge, and are said to remove more than 99.99% of oil and other contaminants. At the same time it reduces exhaust noise by at least 40 dBA, regardless of frequency. Condensate collects in a lower plastic bowl and discharges via a drain. The units are rated for maximum flow rates of 4000 to 12,500 lpm and input pressures from 0 to 16 bar. Temperature range is -10 to 100°C.

Quietair coalescing mufflers from Norgren work much the same as oilremoval filters which cause small oil droplets to merge together into larger drops that fall into a container for removal. In the course of this process, the porous material also reduces noise level of the exhaust air. The units feature a rugged, corrosion-resistant aluminum, steel, and polypropylene construction with a replaceable filtercartridge element. The high-performance cartridge removes up to 99% of oil mist from exhaust air, and a snap-on liquid sump with manual drain collects coalesced oil. Sound-reducing capabilities are also significant. For instance, for an open 1-in. line discharging 105 scfm, adding a silencer reduces sound levels at 2000 Hz from 100 to about 65 dBA. Three male-thread versions have port sizes from ½ to 1-in. NPT and four female-thread version have ports from ½ to 1¼ NPT. Flow ratings are to 15.7 Cv. Maximum pressure rating is 300 psig and maximum temperature is 160°F.

The Numatics Reclassifier is an exhaust coalescing filter/silencer. It is said to remove 99% of the oil and reduces noise up to 25 dBA from exhaust ports on pneumatic systems — even at high flow rates – with low back pressures. The unit’s 1-μm coalescing filters are replaceable. The Reclassifier mounts to exhaust ports on valves or manifolds using a common base or by combining exhaust ports. Mounting it vertically makes use of the oil-catching sump surrounding the filter element and simplifies draining, with manual or continuous drain options available. Maximum temperature rating is 125°F, maximum pressure is 100 psig, and flow ratings range to a flow coefficient of 10. Port sizes range from ½ to 1¼ NPT, and metric threads are available.

Finite Exhaust Coalescing Silencer (ECS), from Parker Hannifin's Filtration & Separation Div., is said to be 99.97% efficient at removing oil aerosols from pneumatic valve, cylinder, and air-motor exhaust. The ECS also acts as a silencer with 25 dBA attenuation, to lower exhaust noise below OSHA requirements. Oil aerosols coalesce into large droplets that collect in a drain sump. The sump can be drained manually or with an attached ¼-in. plastic tube. Maximum ratings are 100 psig and 125°F. The standard units come in ½ and 1-in. NPT port sizes, and BSP (G) threads are available. The ECS units are constructed from the same materials that make up the company’s standard coalescing filter elements. A seamless design ensures media conformity and strength, and provides high efficiency with low pressure drop. Cylindrical perforated steel retainers support the media inside and out. The retainers, galvanized for corrosion resistance, give the units high rupture strength in either flow direction. The ECS can also be used as a high-efficiency inlet or bypass filter for vacuum pumps, or breather elements to protect the air above critical process liquids.