Compressed Air Systems Rely on Proper Filtration

Engineers and system designers often choose compressed air due to the fact that it is readily available and easy to use, but simply setting up the system of piping without strong consideration of air filtration will lead to poor efficiency and inevitable failure. The simple act of compressing air can lead to a rise in air temperature. As the warm air moves through the system, it cools and creates moisture that can wreak havoc on the piping system. In addition to moisture, system designers must also be aware that rust and other contaminants, including oil carryover from the compressor itself, can compromise the efficiency of the system by reducing pressure and increasing energy consumption. For these reasons, designers must contemplate where and how to filter moisture and/or particles from their compressed air systems.

In recent years, filter manufacturers have been incorporating new filter materials to improve flow capacity and capture even smaller particles, down to 0.01 µm, which improves efficiencies to 99.999%, in some cases.

One of the most attractive reasons for using compressed air is its reliability. When properly filtered, compressed air systems can work uninterrupted for millions of hours. But even the tiniest particles can plug small orifices in the system and cause excessive wear or system failure. Proper selection of air filters can prevent probable short- and long-term issues in a pneumatic system.

So what do you need to know about filtration? What are the important factors to consider when choosing the right filter for your application?

Contaminants Come in Small Packages

Filters are rated according to the minimum particle size that their elements will trap. Although filters rated at 40 to 60 µm are adequate for protecting most industrial applications, many point-of-use filters are rated at 5 µm. Finer ratings increase the pressure drop through the filter, which equates to higher energy cost to compress the air. In addition, finer filters clog more rapidly, also increasing pressure drop. Therefore, using a filter finer than necessary does no harm to downstream components, but increases air system operating cost.

Many filter manufacturers will define the expected pressure loss and dirt-holding capacity, using curves related to pressure and flow. Therefore, particle-removal filters should be selected based on acceptable pressure drop and pipe-connection size. A typical pressure drop through such filters would be between 1 and 5 psig. A filter with larger body size will produce less initial pressure loss and provide longer operating life than a smaller-size filter with the same removal ratings.

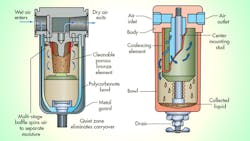

Most point-of-use filters claim to remove condensed water, typically via a form of cyclone separator at their inlet end (Fig. 1). The water-removal efficiency of such filters is highly dependent on the incoming air velocity. Therefore, these filters must be matched to the intended airflow, rather than acceptable pressure drop. If the filter is intended to remove moisture, an integral automatic float-type drain should be provided to periodically remove accumulated liquids from the filter bowl.

Generally, such filters have transparent polycarbonate bowls, which allow easy visual inspection of the sump level. Numerous chemicals can attack this plastic material and it only performs well at pressures below 150 psig and temperatures between 40° F and 120° F. A metal bowl may be required when the filter could be subjected to conditions outside those limits, as well as when synthetic compressor lubricants, which often contain chemicals that are harmful to polycarbonate, are present.

Moisture Barriers

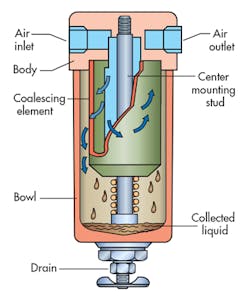

Most oil entrained in a compressed air stream, as well as some of the condensed water, will be in the form of mists or aerosols that can pass through the openings in standard airline filters. Air for instruments, spray painting, and bulk-material conveying frequently requires the removal of such droplets. Coalescing-type filters will accomplish this job (Fig. 2). Aerosol carryover through such filters is commonly stated as parts per million (ppm) of oil vs. air by weight and will range from 1 to as little as 0.01 ppm.

Coalescing filters are often rated to remove aerosols that are substantially smaller than the nominal size of the smallest solid particle that would be captured. Some models offer dual-stage filtration; the first removes solid particulates to protect the coalescing element in the second stage. Because all coalescing filters create a greater restriction to the airflow, pressure losses will be higher than those of conventional compressed air filters.

Coalescing filters have an initial (or dry) pressure drop and a working (or saturated) pressure drop, both based on pressure and flow rate. The effective removal efficiency of such filters depends greatly on the air velocity passing through the filter assembly. Therefore, choose a coalescing filter based on acceptable oil carryover, expected airflow rate, and pipe-connection size. A coalescing filter rated at 0.1 ppm will typically have a clean, wetted pressure drop between 2 and 5 psig, while a high-efficiency filter rated at 0.01 ppm can cause as much as a 10 psig drop once it becomes wetted or fully saturated during service.

The chart below from our Designer’s Guide lists manufacturers of airline filters, and provides sizes, ratings, and specifications about products offered by each company.

Looking for parts? Go to SourceESB.