Download this article as a .PDF

Compressing atmospheric air converts it into potential energy which can be stored, distributed, and used as a source of power for pneumatic systems, tools, and processes. Besides nitrogen, oxygen, and other gasses, atmospheric air contains water, hydrocarbon vapor, and solid particulates ranging in size from sub-micron dust to heavy dirt as large as a millimeter. Compressing this mix concentrates solid contaminants and heats the air so that it holds more water vapor. In addition, oil used to lubricate the compressor can enter the air stream as fine mist, aerosol, or vapor. Even air leaving oil-free compressors can pick up oil vapors from atmospheric air and pass them into the air distribution system.

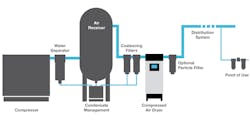

This hot air leaves the compressor via a heat exchanger into the air storage receiver and distribution pipework. As it cools, water and oil vapor condense and turn to liquid or emulsions which can be removed by an efficient condensate management drainage system. However, entrained solid particulates and any remaining water and oil vapor are carried downstream into the distribution system, where the air can pick up more contaminants such as rust and debris from old receivers, treatment equipment, and pipework.

Why, Where, and How?

The problems caused by moisture, particles, and oil in compressed air are straightforward—they make processes less efficient and damage tools and equipment. Contaminants can cause erratic tool operation and premature wear. They reduce fluid power capacity and increase operating costs for compressed air. These contaminants must be removed to keep plants running smoothly.

Bulk contaminants can be removed near the compressor. If the ambient air is dirty, an inlet filter helps keep particles from entering the compressor in the first place. For air leaving the compressor, a water removal filter installed between the outlet and the air receiver reduces the moisture in the stored air. As air in the receiver cools and vapor condenses, liquid water and emulsions fall to the bottom where they can be drained. After the receiver, a coalescing filter may be installed to remove oil aerosols and water carried over from the compressor. If a desiccant dryer is used, oil must be removed first, as oil will cause immediate and complete failure of dryer media.

A general-purpose filter may be installed at the main header as well to remove water and particles. In most industrial applications, a general-purpose filter that removes particles 40 microns and larger is sufficient on the main line. Some applications and environments might dictate additional equipment, such as a dryer or a pressure regulator, be installed on the main air distribution line as well.

Multiple steps are needed to remove water and contaminants from compressed air from the time it leaves the compressor until it reaches the pneumatic tool or equipment it powers.

Point-of-use Filtration

Finally, then, the air has been compressed, the moisture and oil vapors condensed and drained, water removed, and large particles filtered. What next? This general level of air preparation may be enough for many industrial uses, but in many cases, plant managers can make individual tools or groups of tools last longer and operate more efficiently by adding the right filtration, pressure regulation, and lubrication as close as possible to the tool itself.

Applications such as high-speed pneumatic tools or process control instrumentation require filtering out particles down to 5 µm, whereas paint spraying or food-related applications may require filtration down to 1 µm or smaller. But using such a fine filter for the whole distribution system drives up both initial equipment costs and maintenance (filter replacement) costs. It also drives up operating costs because a finer filter makes it harder for air to pass through, resulting in a pressure drop. Increasing air pressure to compensate for pressure drop results in higher compressed air costs.

So how do you select the right point-of-use filtration? The first factor is the requirements of the end-use equipment. Here the most important reference is the operating manual of the equipment itself. The manufacturer of any tool or machine powered by air should specify the appropriate level of filtration in the operating manual. ISO standard 8573-1:2010 Compressed air—Part 1: Contaminants and Purity Classes, specifies purity classes of compressed air with respect to particle, water, and oil.

Once that level is determined, the end-user can specify a filter that meets those requirements. Considerations include:

- Reliable particle removal to the proper level. Keep in mind that even after filtration at the main distribution point, additional contaminants may have been added to the air stream via the pipework.

- Water extraction efficiency. Residual moisture will condense as the air moves through the distribution system.

- Oil removal efficiency. Here again the equipment manual should indicate whether additional oil removal is necessary.

- Appropriate construction for the operating environment. Harsh operating conditions such as outdoor applications, caustic environments, or even salt sea air for offshore operations will take a toll on air preparation equipment. These situations require components with robust construction. Options include 316 stainless steel bodies and specialized sealing materials.

Installing a filter-regulator as close as possible to the tool using compressed air ensures the correct level of particle filtration and pressure regulation. Here, an IMI Norgren B74 helps keep a media blaster operating consistently and productively. (Photo © 2018 Denver Museum of Nature & Science)

To meet these criteria, some applications will benefit from multi-stage filtration: a pre-filter, a fine particle filter, and a coalescing filter to remove oil. Using a pre-filter to remove larger particles prevents the finer filter from clogging and prolongs the service life of the finer filter element. Applications benefiting from three-stage filtration range from instrument air for precision fluid control to large off-shore oil rigs using compressed hydrocarbon gas.

Regulators and Lubricators

Compressed air is not only wet and dirty; it probably leaves the compressor or reservoir at a pressure higher than a given tool or process requires. The addition of a regulator to the airline after the filter will keep the air at optimum pressure. If a tool requires a different pressure than the overall distribution pressure, a regulator should be installed at point of use. Filters and regulators are often integrated into a single unit.

Some tools perform better with consistent lubrication delivered in the air stream. Note that used oil in the air leaving the compressor is degraded and dirty—that is why it needs to be removed. A lubricator added to the filter and regulator delivers a measured amount of clean lubrication that helps tools (even pre-lubed tools) operate efficiently and last longer.

Pneumatics continues to be a safe, practical technology for powering tools and controlling motion in industrial manufacturing and process plants. Using the right filtration at the right place ensures optimum performance service life for tools and equipment.

Point-of-use Filtration Protects Sensitive Tools

When compressed air is used for flowing debris away from fossilized remains, point-of-use filters and regulators ensure precise control of air flow.

A horn. A shoulder blade. Then a beak, a rib, a vertebra. One morning at a construction site in Thornton, Colo., an inspector with a shovel hit a hard bone instead of the soft sandstone he was expecting. Soon thereafter, paleontologists from the Denver Museum of Nature & Science confirmed they had found the horn and shoulder blade of what looked like a Triceratops.

For the next several days, Museum crews excavated bone after bone encased in soft sand and jacketed them in plaster for transport back to the museum. By Friday, visitors to the Museum’s Prehistoric Journey Exhibit could watch volunteers in the paleontology lab meticulously remove the sandstone matrix from the bones of what they would later learn is an extremely rare specimen of horned dinosaur—a Torosaurus.

The dinosaur may be rare, and the setting exotic, but the demands on the lab’s pneumatic tools are as rigorous as any plant that runs, as this lab does, 364 days a year.

Like a typical factory or shop, the lab uses pneumatic tools for many tasks. Volunteers use pneumatic scribes—tiny jackhammers with carbide tips and strokes measured in millimeters—to carefully chisel the stone matrix away from fossilized bones and teeth. Media blasters blow sodium bicarbonate to remove the matrix from specimens too fragile to scrape. Preparators use air nozzles to remove bubbles from mold-making materials as they create research quality casts of fossils too valuable and delicate to travel.

All of these applications require clean, dry air. But they didn’t always get it. An old compressor that threw off oil, mainline-only filtration, and a legacy piping system of copper and black pipe took their toll on the sensitive tools. In particular, scribes had to be taken out of use, disassembled, cleaned, and rebuilt every couple of months because particles and moisture impaired consistent performance. Preparing a fossil is slow, painstaking work, and tool downtime was making the process even slower.

Things began to change when a like-new compressor from another part of the museum became available and the number of work stations was increased from 10 to 28. A lab volunteer, a retired IMI Norgren application engineer, saw this as a chance to upgrade to point-of-use filtration for the scribes and air nozzles. Norgren Inc., donated IMI Norgren B07 miniature filter/regulators to remove moisture and particles down to 5 µm in air destined for two scribes at each station.

Volunteers can alternate between the two tools depending on what size is required for the job. They also use the regulator to control the pressure for specific tools and tasks, ranging from 130 psig down to 40 psig. Since the addition of point-of-use filtration about two years ago, the lab has seen a significant decrease in the number of tools that need to be repaired or replaced.

Each workstation in the paleo lab at the Denver Museum of Nature & Science has point-of-use filtration and regulation, practically eliminating downtime for tools damaged by contaminants and moisture carried in compressed air. (Photo © 2018, Denver Museum of Nature & Science)

In addition to the B07s, Norgren donated larger filter-regulators for the media blasters and lockout/tagout valves for emergency shutoffs. It also donated fittings and tubing to allow scribes and nozzles to be moved easily to work around larger specimens—some weighing as much as 3,000 lb.

Now the more-than-100 prep lab volunteers, the largest contingent of any museum in the U.S., can rely on their pneumatic tools to work consistently and productively. And the visitors watching them through the glass learn not only about the prehistoric fish, turtles, birds and, of course, dinosaurs, but also a little something about pneumatics as well.

Charles Werdehoff is FRL product marketing manager, Americas at IMI Norgren.